Technology Encyclopedia

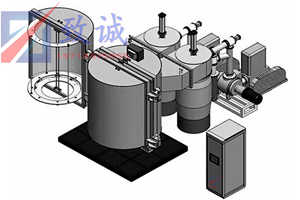

How to maintain the vacuum coating machine

When the buyer purchases the vacuum coating machine, the manufacturer Shengchang equipment will generally be equipped with a machine maintenance manual. Both the buyer and the manufacturer attach great importance to the maintenance of the vacuum coating machine.

Why does the evaporation coating machine coat under vacuum conditions

If the pressure is not low enough (or the vacuum degree is not high enough), good results cannot be obtained. For example, if aluminum is deposited on the order of 10 2 Torr, the obtained film is not only not bright, but even gray and black. And the mechanical strength is extremely poor.

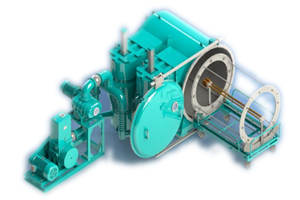

What is the difference between PVD vacuum coating machine and CVD coating machine?

Thin film deposition technology is mainly divided into three major processes: physical, chemical, and epitaxy. Physical vapor deposition is referred to as PVD vacuum coating machine. Chemical vapor deposition is referred to as CVD coating machine for short.

Vacuum conditions in the process of vacuum evaporation coating machine

In the vacuum chamber, when the particle concentration in the gas phase and the pressure of the residual gas are low enough, these particles can keep flying in a straight line from the evaporation source to the substrate, otherwise, they will collide and change the direction of motion.

Common problems of PVD evaporation process and sputtering process

Vacuum coating equipment uses two common coating processes, evaporation and sputtering. These two processes are currently the most popular and widely used, and their attention is naturally much higher than other processes.

Development and Application of Coating Technology for Ion Plating Equipment

Vacuum multi-arc ion coating machine technology Titanium plating is a process for surface treatment of metal materials. It has been widely used in the industrial field and has the intention to gradually promote it.

Advantages of vacuum coating process technology

Vacuum coating makes the plastic surface have a metallic texture; because compared with aluminum, copper, iron, stainless steel and other metal parts, the manufacturing process of plastic parts has unique advantages such as large batches, low cost and easy processing.

Vacuum coating machine coating related knowledge questions and answers

Although PVD coating technology can be used to plate high-quality films, the cost of PVD coating process is actually not high. It is a very cost-effective surface treatment method, so PVD coating technology has developed very fast in recent years.