industry news

What is the difference before and after the workpiece is plated by the vacuum coating machine?

Vacuum coating machines are widely used in various industries, including machinery, electronics, hardware, aerospace, medical, chemical and other fields.

Vacuum coating machine design should pay attention to details

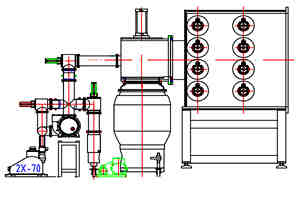

In order to ensure that the vacuum coating machine has good sealing performance, it is necessary to cut off the cause of possible leaks at the source

How to check for leaks during installation and commissioning of vacuum coating machine

The leak detection link of the vacuum coating machine is a step that needs to be carried out in all links from design, manufacture, commissioning, use, etc., and it is absolutely necessary.

Vacuum coating machine sputtering sputtering process introduction

The sputtering method can be used to prepare material films with high melting point and low vapor pressure that cannot be prepared by the evaporation process, which is convenient for the preparation of thin films of compounds or alloys. The vacuum coating machine sputtering sputtering process is mainly used for sputtering etching and film deposition. .

Which products can the ion vacuum coating machine be used on?

Tableware, kitchen utensils, furniture, toys, and daily decorations that are closely related to our daily life have been coated with a layer of film by an ion vacuum coating machine. This technology and equipment has become an indispensable indirect necessity in our life.

Introduction to basic knowledge of PVD coating of vacuum coating machine

PVD (Physical Vapor Deposition) technology is mainly divided into three categories, vacuum evaporation coating, vacuum sputtering coating and vacuum ion coating. Compared with the three classifications of PVD technology, the corresponding vacuum coating equipment also includes vacuum evaporation coating machine, vacuum sputtering coating machine and vacuum ion coating machine.

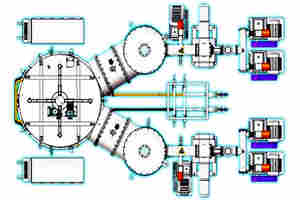

The vacuum coating machine can be classified according to the function of the vacuum furnace

Vacuum coating equipment is distinguished according to the principle of thin film: it can be divided into sputtering coating, ion coating, evaporation coating and chemical vapor deposition coating. According to the purpose of application, it can be divided into optical coating, winding coating, decorative coating, solar heat collector coating, tool coating, architectural coating, conductive coating and so on. the