OTHER PRODUCTS

Coating equipment

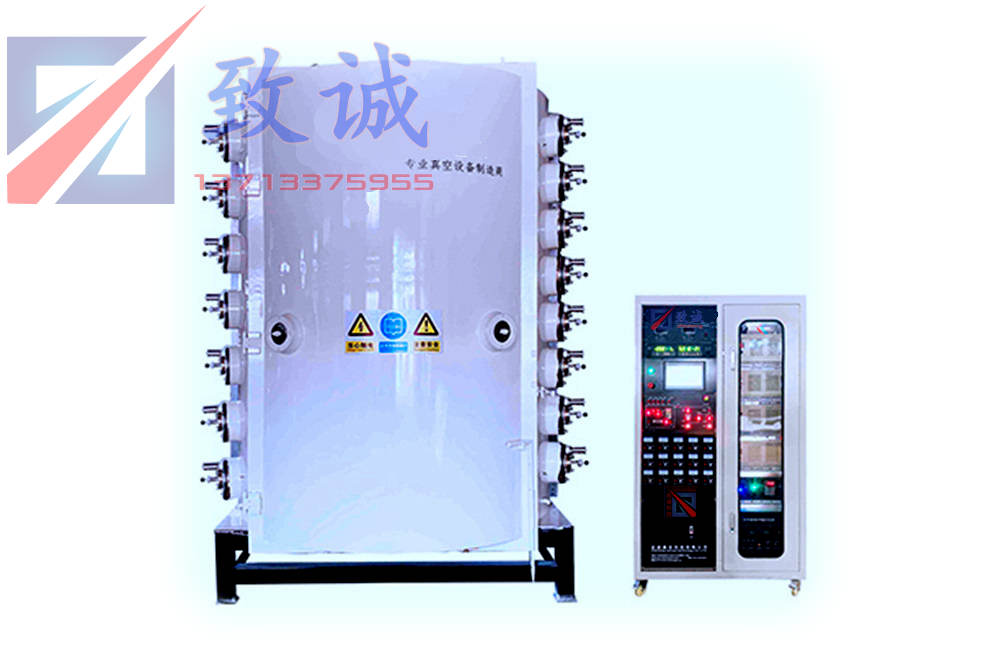

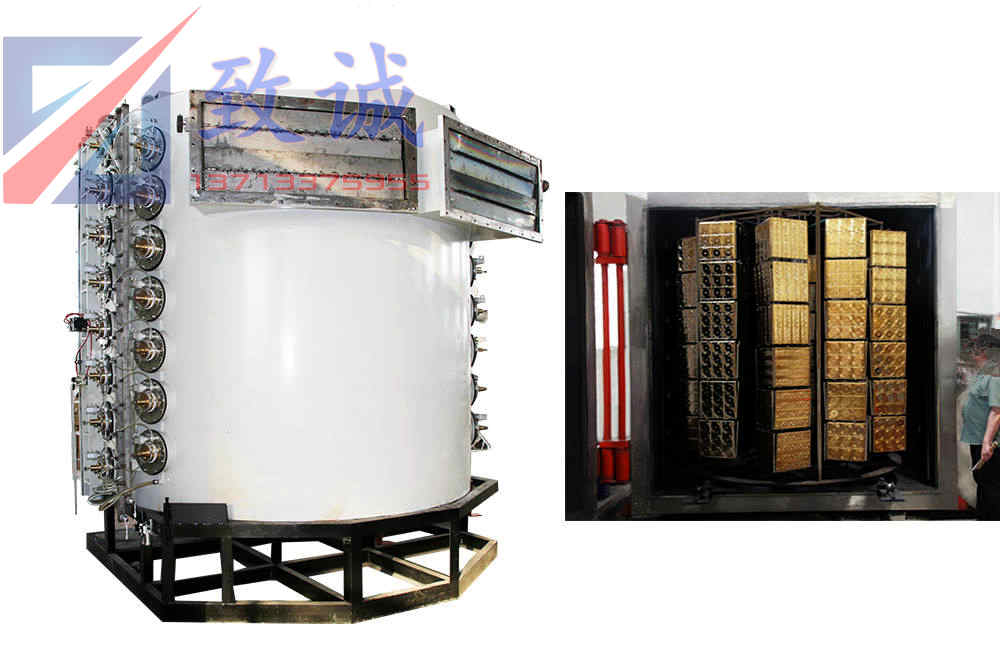

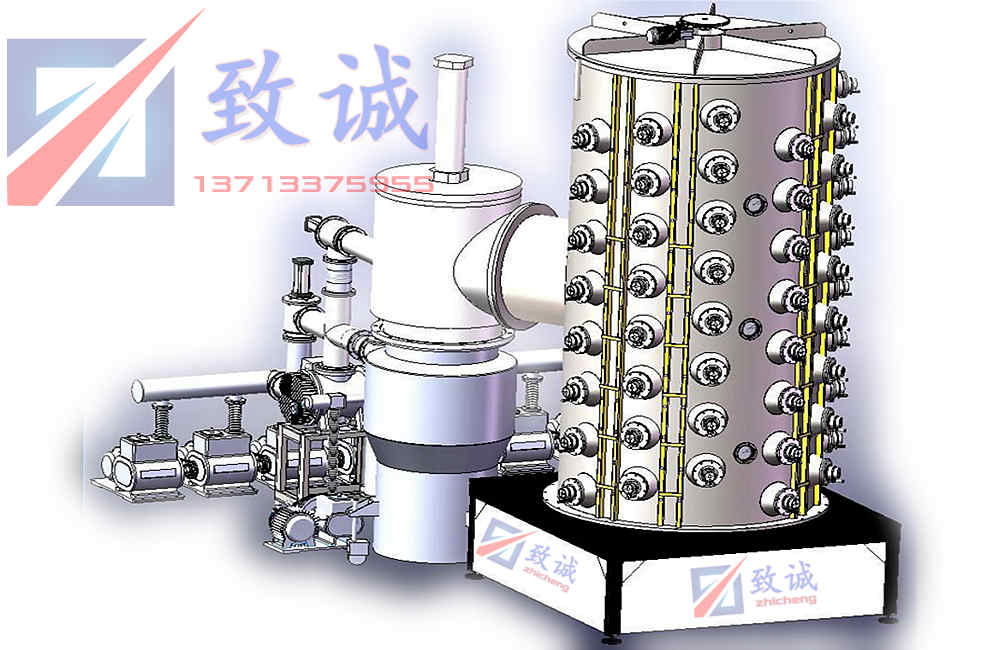

Large Stainless Steel Coating Machine - Stainless Steel / Hardware / Furniture / Pipe / Building Materials

Large vacuum ion coating equipment

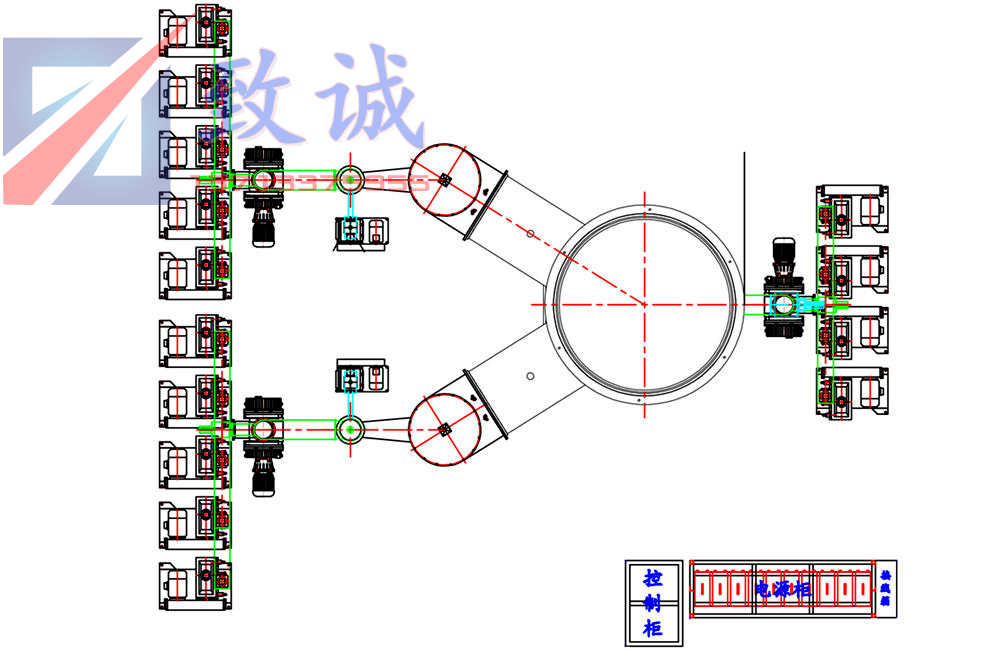

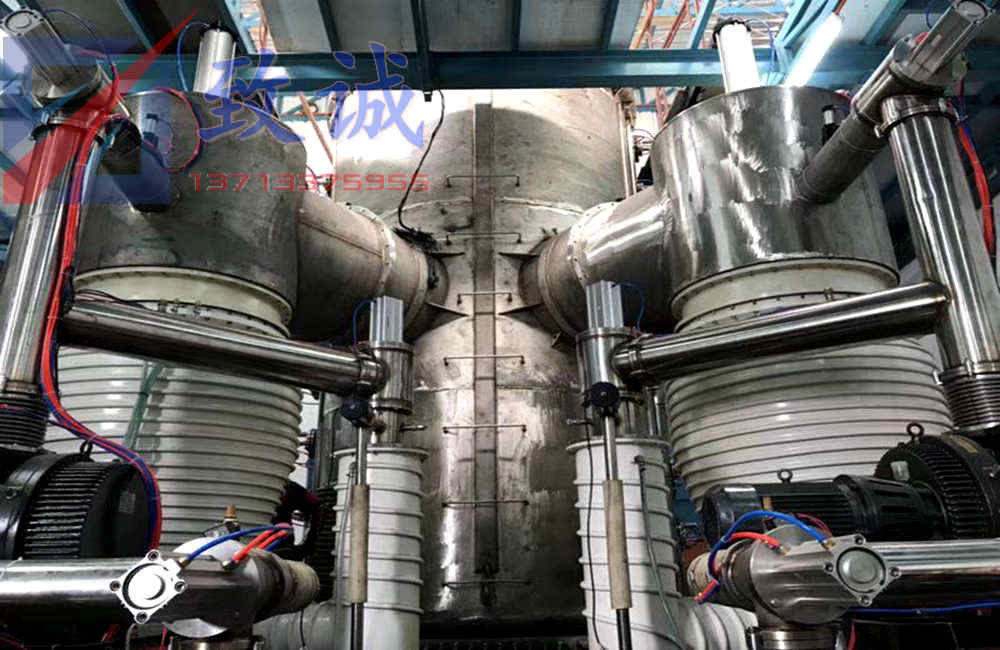

The equipment is specially designed for hardware furniture, ion-plated decorative film on stainless steel decorative panels. The ion-plated film has a real metallic texture, which is incomparable to chemically plated stainless steel color plates. The equipment is equipped with three sets of high-pumping vacuum units, with fast pumping speed and short working cycle; 34~56 circular arc targets are used, the target positions are reasonably arranged, and pulse bias system is equipped, the film layer has good bonding force, uniform color, touch screen +PLC control, computer automatic control can be realized, manual/automatic control can be switched at any time, reliable and stable operation, high yield.

The large-scale vacuum ion coating equipment developed by Dingyi Technology is safe, environmentally friendly, and stable in process. The film layer is rich in color, uniform in color, wear-resistant, corrosion-resistant, high-temperature resistant, good adhesion and not easy to fade.

TiN titanium gold decorative film can be plated; TiC, CrC gun black, black, gray series film; ZrN zirconium gold, champagne gold, brass series film; TiCN rose gold, rose red, wine red, brown series film layer; TiO sapphire blue, emerald green, pink, iridescent series of coating layers.

Widely used in stainless steel plates, stainless steel pipes (up to 6 meters), stainless steel display racks, stainless steel LOGO signs, locks, handles, hardware bathrooms, stainless steel tableware and other stainless steel products, plastic electroplating parts, ceramics and other surface coating processes.

Advantage:

• Low operating cost and fastest production cycle ensure highest industry standard and most competitive cost, low material and energy consumption

• Tailor-made design services according to customers' production needs

• Fast, flexible production cycles and flexible, versatile production systems capable of running at the fastest cycles on the market, with automatic control systems to eliminate human error

• All phases of operation are managed by a PC with automatic archiving and backup, which provides real-time reports, system and cycle status data, informing and guiding the operator throughout the process.

Technical Parameters:

|

Machine Size Item

|

Ф2000*H3000MM | Ф2200*H3600MM | Ф2500*H4200MM | Ф2500*H4500MM |

|

|

4 PCS | 5 PCS | 6 PCS | 7 PCS |

Configuration |

2X-70 * 8 SETS ZJP-1200 * 2 SETS KT-800 * 2 SETS 2X-30 * 1 SET |

2X-70 * 8 SETS ZJP-1200 * 2 SETS KT-1000 * 2 SETS 2X-30 * 1 SET |

2X-70 * 10 SETS ZJP-1200 * 2 SETS KT-1000 * 2 SETS 2X-30 * 1 SET |

2X-70 * 12 SETS ZJP-1200 * 3 SETS KT-1000 * 2 SETS 2X-30 * 1 SET |

|

|

32 | 36 | 40 | 46 |

|

|

200KW | 220KW | 240KW | 260KW |

|

|

Public Rotation,Frequency control of rotation speed |

|||

|

|

Manual/Full Automatic mode. Touch screen+PLC |

|||

|

|

8.0*10-4 Pa | |||

|

|

Titanium Gold, Champagne, Japan Gold, Rose Gold, Copper, Gun Black, Rainbow,SS Silver,etc. |

|||

Remarks |

The data is based on the regular machine size, we provide OEM service for the unique product. |

|||

Coating example:

Zhicheng Technology

Vacuum coating machines of various specifications and models can be designed according to user requirements.

The vacuum unit and electronic control system can also be designed and configured according to user requirements.

Zhicheng Technology's world-leading coating application solutions: provide equipment, materials, processing, technology, project support and other system services

Zhicheng vacuum coating equipment includes: evaporation coating machine, magnetron sputtering coating machine, magnetron evaporation dual-purpose coating machine, multi-arc ion coating machine, intermediate frequency ion coating machine, AF coating machine, super hard coating coating machine, winding Type coating machine, PVD coating line, coating project supporting assembly.

PVD process technology uses vacuum conditions to deposit various metal and non-metal films on the surface of plastic parts by means of distillation or sputtering.

Zhicheng Technology matches the best coating process scheme according to the characteristics of the product.

The advantages and characteristics of Zhicheng vacuum coating machine ancestor equipment in the industry are: professionalism, integrity and reliability.

VIDEO