OTHER PRODUCTS

Coating equipment

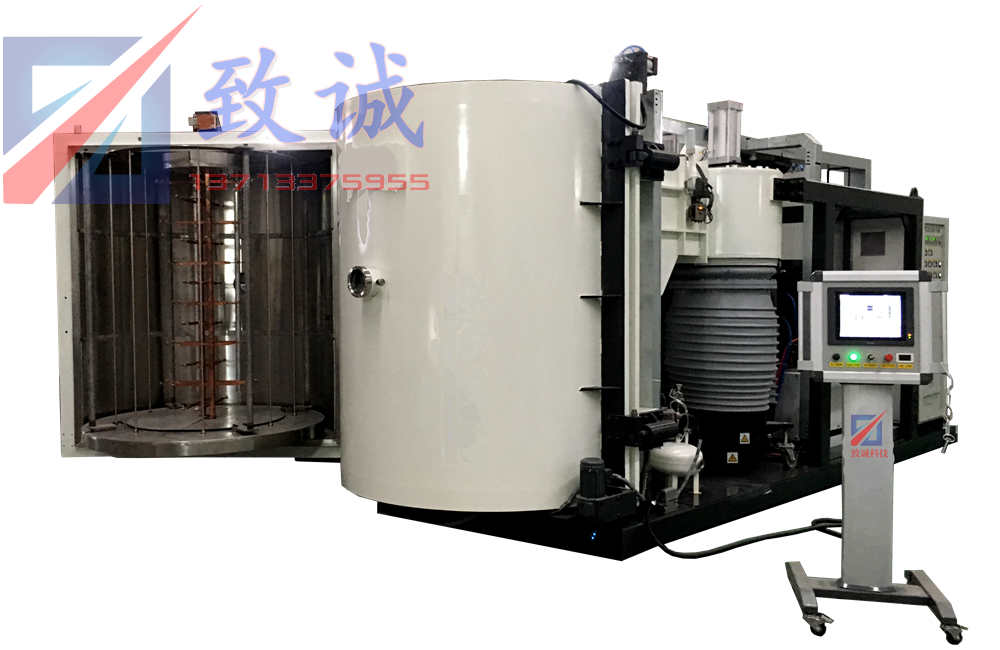

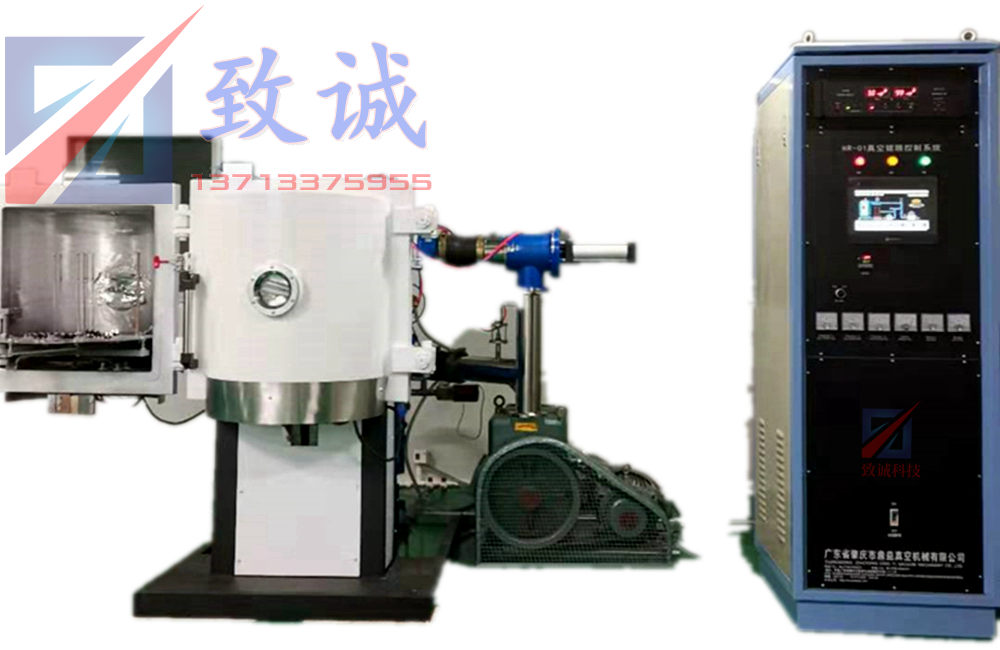

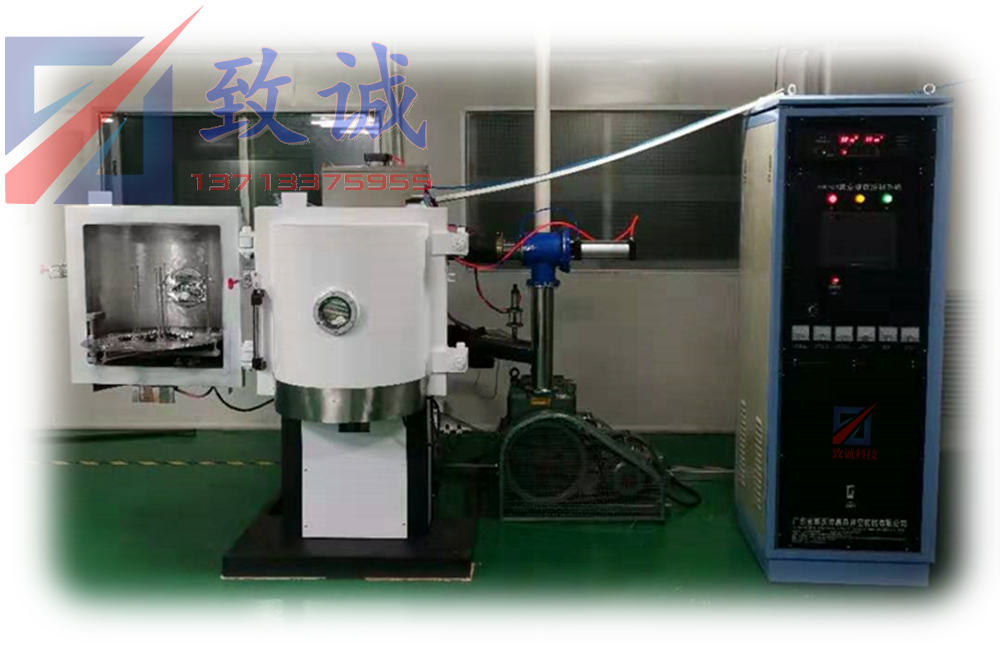

Lamp shade inner plating equipment - evaporation coating machine

Lamp shade - cup set: vacuum PVD internal plating machine: evaporation coating machine is specially developed for the internal coating of advanced jewelry and devices.

PVD internal evaporation coating machine can be used to coat glass, ceramic, plastic and other bottle, tank and spherical inner walls. It is composed of vacuum chamber body, air extraction system, electric control system and evaporation system. Several plated workpieces are buckled on the clamping plate, the door is closed, and the air is pumped quickly. In the vacuum state, the metal film material is evaporated by resistance heating, and the vapor condenses on the inner surface of the workpieces to form the required film.

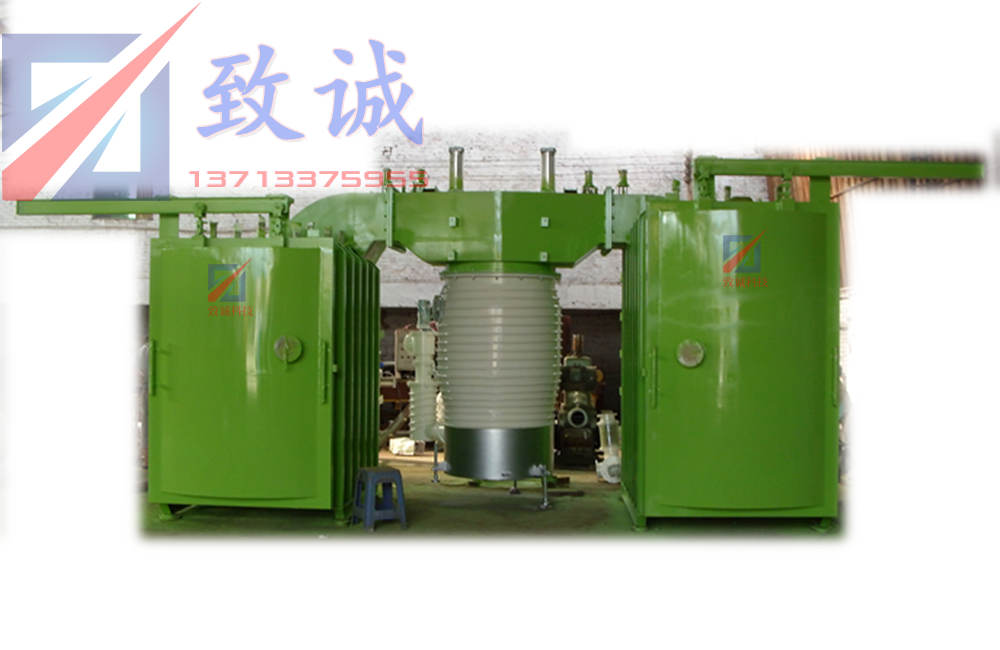

Vacuum evaporation coating equipment (evaporation coating for short) is a technology that uses evaporator to heat and vaporize the evaporated material under vacuum conditions, and the evaporated particle stream is directly directed to the substrate and deposited on the substrate to form a solid film. The preparation and process of vacuum evaporation coating technology is relatively simple. It can not only deposit very pure films, but also prepare films with specific structures and properties. It is a very important coating technology today. The double-door design is convenient for product loading. While one door is in production, the other door can be used for loading and unloading.

Equipment advantages:

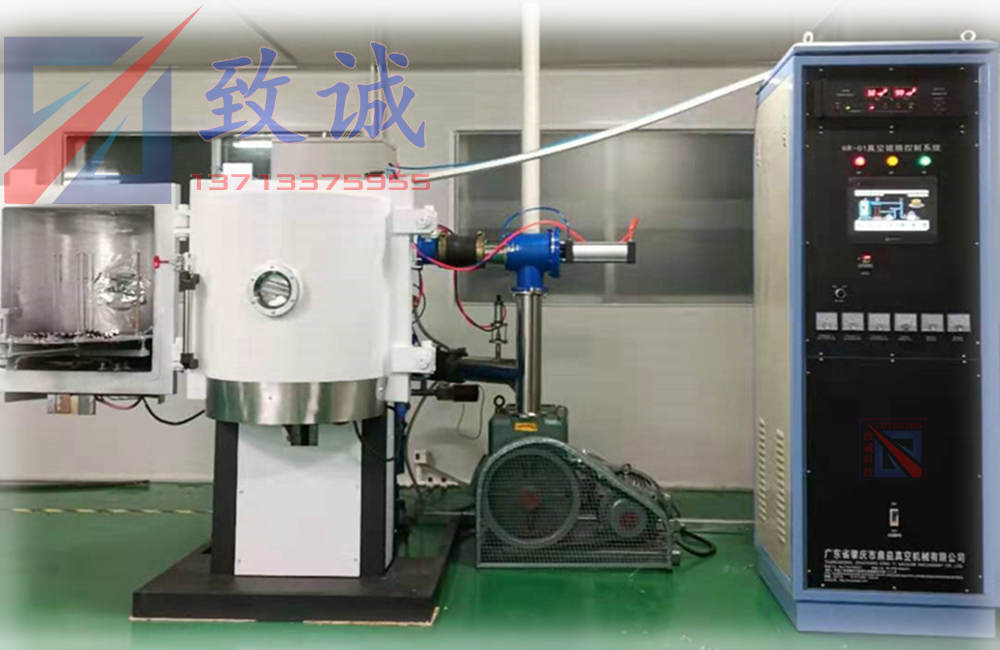

Zhicheng vacuum technology evaporation coating equipment makes aluminum film bright, delicate, fast coating speed, high efficiency, simple operation, and stable equipment. The film is firm, bright, and not easy to be contaminated. The film with high density, high purity, and uniform film thickness can be obtained.

Technical parameters:

1、 The equipment adopts vertical structure, and the vacuum chamber size is F600X600, F600X600, F600X600, (high)

2、 The workshop is equipped with evaporation mechanism. Place the glass on the third floor.

3、 Glasses or glass balls with caliber of F30 to F200mm can be plated each time, for example, glasses with caliber of F50mm can be plated with about 60 glasses each time.

4、 The electric control system is equipped with semi-automatic/manual dual control function, equipped with automatic vacuum measuring instrument, and fully automatic evaporation control.

5、 Equipped with vacuum unit:

① Two K-500 diffusion pumps;

③ One 2X-70 slide valve pump;

④ Two 2X-4 rotary vane pumps.

6、 Vacuuming cycle: empty from the atmosphere to 5x10 ˉ² Pa is less than 6 minutes.

Note: The size of vacuum chamber can be customized according to customer's product and special process requirements

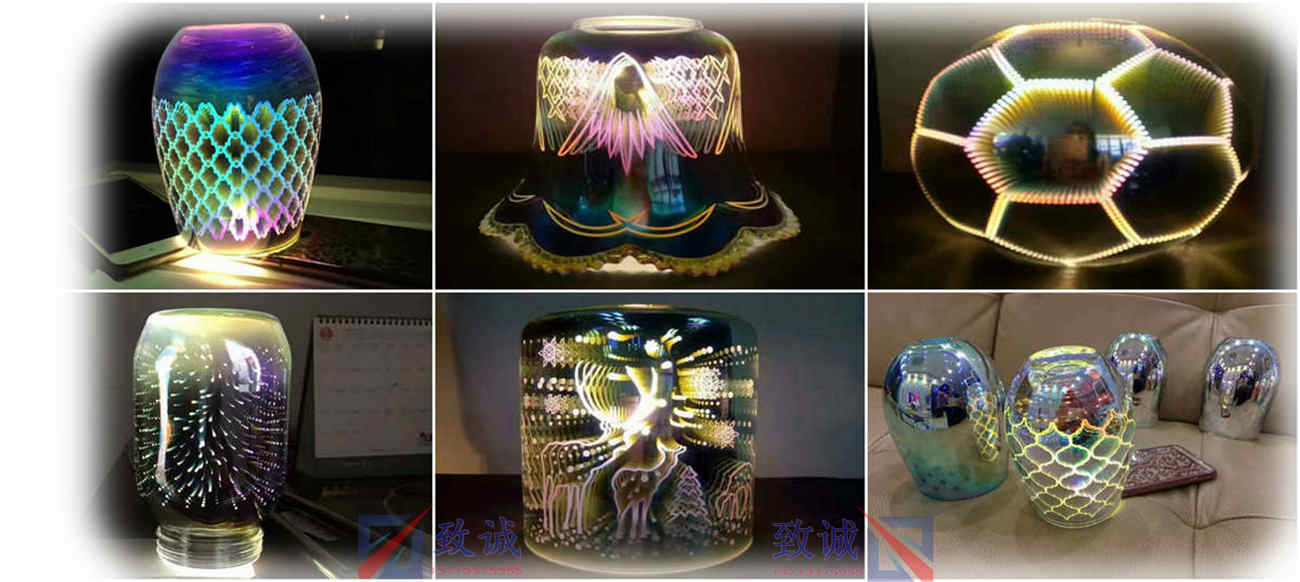

Example of inner plating sample:

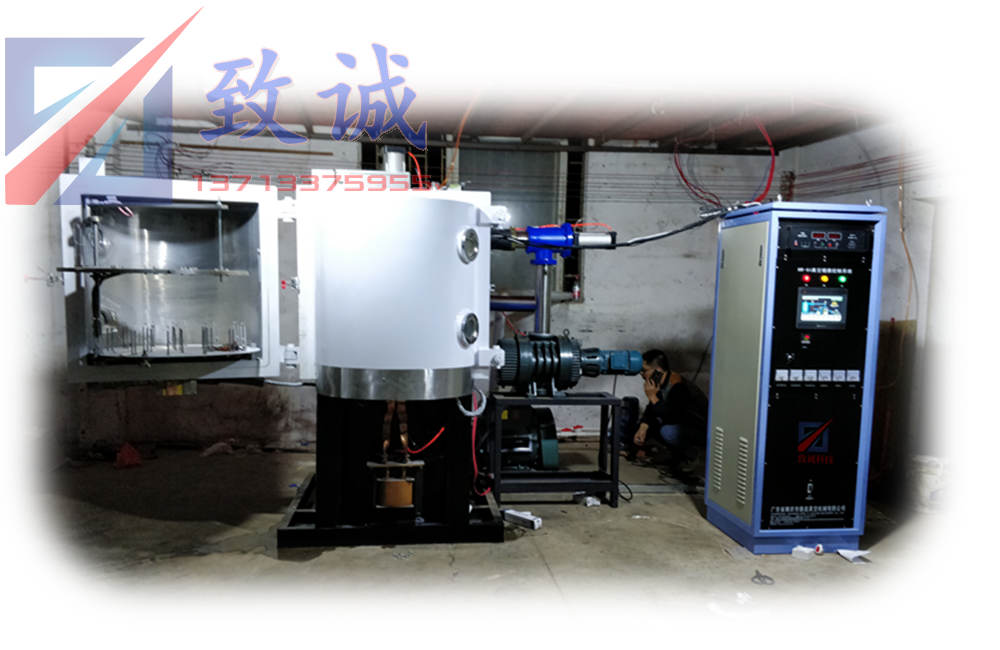

Zhichenggao vacuum evaporation coating machine: aluminum plating machine, mirror plating machine, color plating machine

It has the advantages of reasonable structure, large pumping speed, short working cycle, high production efficiency, convenient operation, low energy consumption, stable operation, uniform film layer and good film quality.

The equipment is mainly used in automobile, audio, various small household appliances, computers, clocks, mobile phones, reflective glasses, cosmetics, toys and other industries.

Processable materials include ABS, PS, PP, PC, PVC, TPU, nylon, glass, ceramics, metal, etc.

The surface state of the substrate that can be plated: electroplating bright surface, semi-transparent mirror surface, matte surface (semi-dumb, full-dumb), process electroplating wrinkles, wire drawing, raindrops, etc;

The plating colors include gold, silver, red, blue, green, purple, black, seven colors, etc

Zhicheng Technology

Vacuum coating machines of various specifications and models can be designed according to user requirements.

The vacuum unit and electronic control system can also be designed and configured according to user requirements.

Zhicheng Technology's world-leading coating application solutions: provide equipment, materials, processing, technology, project support and other system services

Zhicheng vacuum coating equipment includes: evaporation coating machine, magnetron sputtering coating machine, magnetron evaporation dual-purpose coating machine, multi-arc ion coating machine, intermediate frequency ion coating machine, AF coating machine, super hard coating coating machine, winding Type coating machine, PVD coating line, coating project supporting assembly.

PVD process technology uses vacuum conditions to deposit various metal and non-metal films on the surface of plastic parts by means of distillation or sputtering.

Zhicheng Technology matches the best coating process scheme according to the characteristics of the product.

The advantages and characteristics of Zhicheng vacuum coating machine ancestor equipment in the industry are: professionalism, integrity and reliability.

VIDEO