DLC

DLC (diamond like carbon)

"DLC" is the abbreviation of "diamond-like carbon". DLC is a kind of material which is composed of carbon, similar to diamond in nature, and has graphite atomic structure. Diamond like carbon (DLC) film is a kind of amorphous film, because of its high hardness and high elastic modulus, low friction coefficient, wear resistance and good vacuum tribological properties, it is very suitable for wear-resistant coating, which has attracted the attention of tribological circles.

1. Mechanical properties

a. Hardness and elastic modulus. The hardness and elastic modulus of DLC films prepared by different deposition methods are very different. DLC films with hardness up to or even higher than diamond can be prepared by magnetic filtered cathode arc method.

b. Internal stress and bonding strength. The internal stress and bonding strength of DLC film are two important factors that determine the stability and service life of the film and affect the performance of the film. The DLC film with high internal stress and low bonding strength is easy to crack, fold and even fall off in the application, so the DLC film had better have moderate compressive stress and high bonding strength.

2. Friction performance

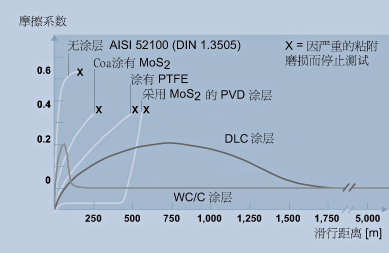

DLC film not only has excellent wear resistance, but also has very low friction coefficient, generally less than 0.2, which is an excellent surface anti-wear modified film. The friction coefficient of DLC varies with the preparation process and the composition of the film, and the lowest friction coefficient can reach 0.005 [13]. Doping metal elements may reduce the friction coefficient, but adding h can improve the lubrication effect, and the environment also has a certain influence on the friction coefficient. But in general, DLC film has obvious advantages in friction coefficient compared with traditional hard films (such as tin, tic, TiAlN, etc.), and the friction coefficient of these traditional hard films is more than 0.4. Therefore, DLC film may replace these traditional hard coatings in many tribological fields.

3. Thermal stability

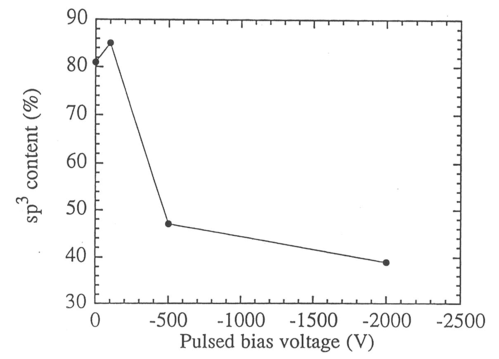

Because DLC is a metastable material, the poor thermal stability is an important factor limiting the application of DLC films. When annealed at above 300 ℃, SP3 bond changes to SP2 bond. Therefore, a lot of work has been done to improve the thermal stability of DLC films. It has been found that the thermal stability of DLC films can be significantly improved by the addition of Si. The SP3 to SP2 bond transition of DLC films containing 20 at% Si occurs only after annealing at 740 ℃. The thermal stability of DLC films can also be improved by the addition of metal (such as Ti, W, Cr).

4. Corrosion resistance

Pure DLC film has excellent corrosion resistance, which is difficult to be eroded by various acids, alkalis and even aqua regia. However, the corrosion resistance of DLC films doped with other elements decreases because the doped elements are eroded first, which destroys the continuity of the films.

5. Surface state

The surface of DLC film is generally smooth, which has little effect on the surface finish of substrate, but with the increase of film thickness, the surface finish will decrease. The surface finish of DLC films obtained by different deposition methods is also different.

DLC film has good adhesion resistance, especially for non-ferrous metals (such as copper, aluminum, zinc, etc.), plastics, rubber, ceramics, etc.

Diamond like carbon (DLC) coating technology:

Different types of diamond-like carbon coatings have different production technologies. DLC coating is suitable for extreme wear and high relative speed, even under the condition of no lubrication operation. It has excellent wear resistance, anti-oxidation and adhesion (anti-wear). It can withstand the surface pressure that will immediately cause wear and cold welding under normal conditions, and minimize the friction loss. Good corrosion resistance can protect the substrate from destructive attack.

DLC film, known as amorphous carbon film, has excellent wear resistance, anti-oxidation and adhesion, which is suitable for extreme wear and high relative speed applications.

Diamond like carbon (DLC) coating technology:

Different types of diamond-like carbon coatings have different production technologies. DLC coating is suitable for extreme wear and high relative speed, even under the condition of no lubrication operation. It has excellent wear resistance, anti-oxidation and adhesion (anti-wear). It can withstand the surface pressure that will immediately cause wear and cold welding under normal conditions, and minimize the friction loss. Good corrosion resistance can protect the substrate from destructive attack.

DLC film, known as amorphous carbon film, has excellent wear resistance, anti-oxidation and adhesion, which is suitable for extreme wear and high relative speed applications.

DLC coating type:

a - C Hydrogen free amorphous carbon film

ta - C Tetrahedral hydrogen free amorphous carbon films

a - C:Me Metal doped chlorine free amorphous carbon films (me = w,

a - C:H Amorphous carbon films containing hydrogen

ta - C:H Tetrahedral amorphous carbon films containing hydrogen

a - C:H:Me Metal doped amorphous carbon films containing hydrogen (me = w,

a - C:H:X Modified amorphous carbon film containing chlorine (x = Si,

Application:

1. Drill, milling cutter

DLC film can be applied to drill bit and milling cutter, especially metal doped DLC film. It has not only high hardness, but also low friction coefficient and anti-ferrous metal bonding. The metal doped DLC film prepared by Hauser company in Holland can reduce the so-called chip bump on the surface of high strength aluminum alloy. The result is a longer tool life and a smoother surface of the workpiece material after cutting. Especially in dry cutting and deep hole processing, the film has very good performance.

2. Optical disc mould and its auxiliary mould

The die for CD, CDR and DVD is an important tool to produce CD, CDR and DVD. In order to reduce the friction between the die and the master disk (nickel disk), we hope that the die surface is hard and the friction coefficient is small. At present, most foreign countries use DLC film, which greatly improves the life of the die and the quality of the disk. After coating, it has the characteristics of high hardness, low friction coefficient, wear resistance, corrosion resistance, good adhesion resistance and environmental protection.

3. Mandrel

The wear resistance, friction reduction and corrosion resistance of DLC film can significantly improve the service performance and service life of gear, mandrel and other moving parts.

4. Application on blade

Now DLC is also used in all kinds of blades, such as scissors, razors and so on. The DLC film reduces the friction between the blade and the skin, improves the performance of the blade and prolongs its service life.

5. Application on key parts

DLC film can also play its excellent performance in many key parts, such as the application in piston. By using its low friction coefficient, it can reduce friction, improve wear resistance, and meet the requirements of oil-free lubrication and service life. Instead of the original plating hard chromium treatment, the DLC coating on the sewing machine shuttle spindle not only avoids the problem of polluting the environment, but also significantly improves the surface hardness and wear resistance of the workpiece, and the service life is increased by more than 10 times. At the same time, because of the reduction of the friction coefficient of the surface film layer, the noise generated during the running of the machine becomes smaller.

6. Other applications

There are many other applications of DLC film in tooling, such as powder metallurgy molding mold, plastic molding mold, lead frame bending mold, glass molding mold, magnesium alloy processing mold, in bearing and so on.

PRODUCTS