Server-Online

137-1337-5955

13713375955

In our daily life, many household items are coated with a layer of film by a coating machine, making the product not only more beautiful, but also more practical. But many people have a question, since it is coated with a layer of film, the film must have a thickness, so how thick is the film thickness, and how to measure it?

Zhicheng Technology will introduce in detail how to measure after the film of the vacuum coating machine.

The thin film must be deposited on the substrate, so there is no way to talk about thin film deposition without the substrate. The cleaning quality of the substrate has the most important influence on the quality of the film. At the same time, the thickness of the film must also be known in the production of the film. It is meaningless to talk about the measurement of the properties of the film without the thickness of the film. Therefore, the measurement of the film thickness and the cleaning of the substrate can be said to be important technologies related to thin film production. Generally, the so-called thickness refers to the distance between two completely flat parallel planes. This concept is a geometric concept.

The ideal film thickness refers to the distance between the substrate surface and the film surface. In the three-dimensional measurement of film morphology, relative to the thickness of the film, the other two-dimensional measurements can be said to be infinite. Since the actual surface is uneven and discontinuous, and there may be pores, impurities, lattice defects and surface adsorbed molecules inside the film, it is necessary to strictly define and accurately measure the thickness of the film. is very difficult.

The definition of film thickness should be determined according to the method of site survey and the purpose of site survey. Therefore, for the same film, different measurement methods will give different results, that is, different thicknesses.

The surface in thin film oil measurement is not a geometric concept, but a physical concept, which refers to the collection of surface molecules (atoms). The average surface means that the algebraic sum of the distances from all points on the surface atoms to this surface is equal to zero, and the average surface is a geometric concept.

We usually refer to the average surface of the collection of surface molecules on one side of the substrate as the substrate surface; the average surface of the surface on the side of the film that is not in contact with the substrate is called the shape surface of the film. The atoms are rearranged so that the density is exactly the same as that of the bulk solid material and evenly distributed on the surface of the substrate. At this time, the average surface is called the equivalent surface of the film quality; according to the physical properties of the measured film, it is equivalent to a length The average surface of a thin film of a bulk solid material having the same width as the measured thin film is called the equivalent surface of the thin film property. Shape film thickness is the film thickness closest to the intuitive form, usually in µm; quality film thickness reflects the amount of substances contained in the film, usually in µg/cm#8217; Useful, and relatively easy to test the most.

Since the actual surface is not smooth, and there are inevitably various defects, impurities and adsorbed molecules in the film production process, no matter which method is used to define and measure the film thickness, it is an average value, and The thickness value of the film is sufficient to include impurities, defects, and adsorbed molecules.

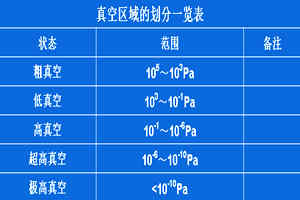

Vacuum coating machine coating is carried out in a vacuum chamber. For measuring the thickness of the film, a professional measuring instrument is needed to measure the thickness.

How does the vacuum coating equipment technology make gradient colors?

2023-03-03

How does the vacuum coating equipment technology make gradient colors?

2023-03-03

Standing at the forefront of market and consumer requirements, bold design can be invincible. Vacuum coating equipment processing gradient color can be said to be a popular color this year. Since the Huawei P20 was sold, everyone has confirmed that gradient color has been a design trend in the past two years.

Why use high-purity gas in vacuum coating

2023-03-03

Why use high-purity gas in vacuum coating

2023-03-03

After high-purity coating metal (such as aluminum) is evaporated at high temperature, it will freely fly away and settle on the surface of the workpiece to form a coating. Argon is a protective gas to prevent the oxidation reaction from affecting the coating quality. In the work of vacuum ion coating equipment, the color of liquid gas will be different when different gases are selected.

Dingyi Technology takes you to understand the composition and structure of the vacuum coating machine

2023-03-03

Dingyi Technology takes you to understand the composition and structure of the vacuum coating machine

2023-03-03

With the progress of society, vacuum coating machine technology is also changing with each passing day. Optical coating technology, winding coating technology, decorative coating technology, and magnetron coating technology have already been put into market use in large quantities to meet the current market demand.

Encyclopedia of various vacuum pump technologies, a must-read for vacuum coating equipment engineers

2023-03-03

Encyclopedia of various vacuum pump technologies, a must-read for vacuum coating equipment engineers

2023-03-03

A vacuum pump is a device that uses various methods to generate, improve and maintain vacuum in a closed space. A vacuum pump can be defined as a device or device that uses mechanical, physical, chemical or physicochemical methods to evacuate the evacuated container to obtain a vacuum.

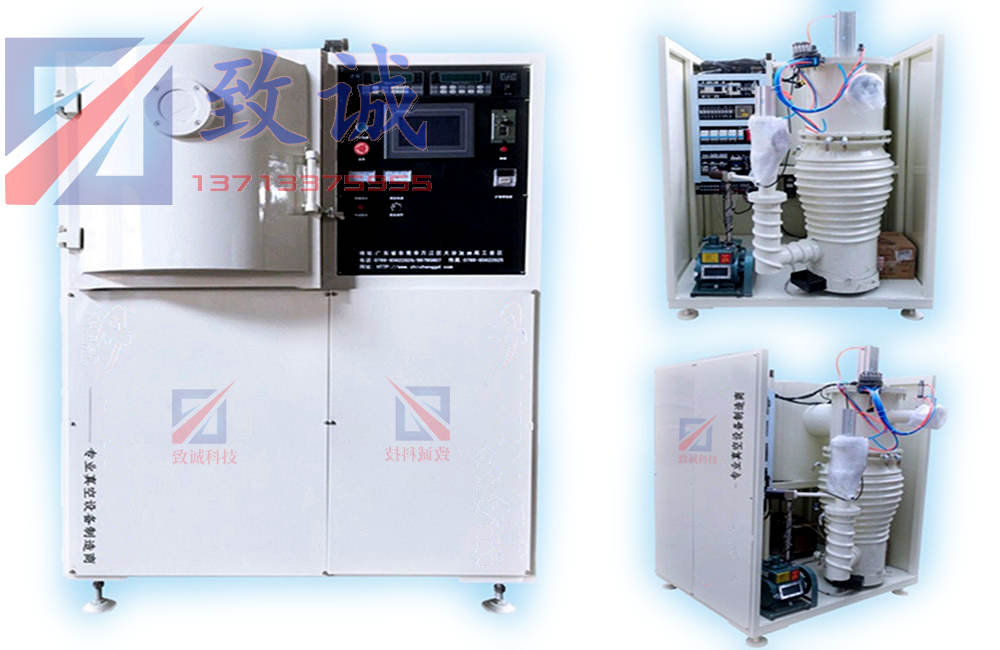

Vertical double-door-high vacuum evaporation coating machine

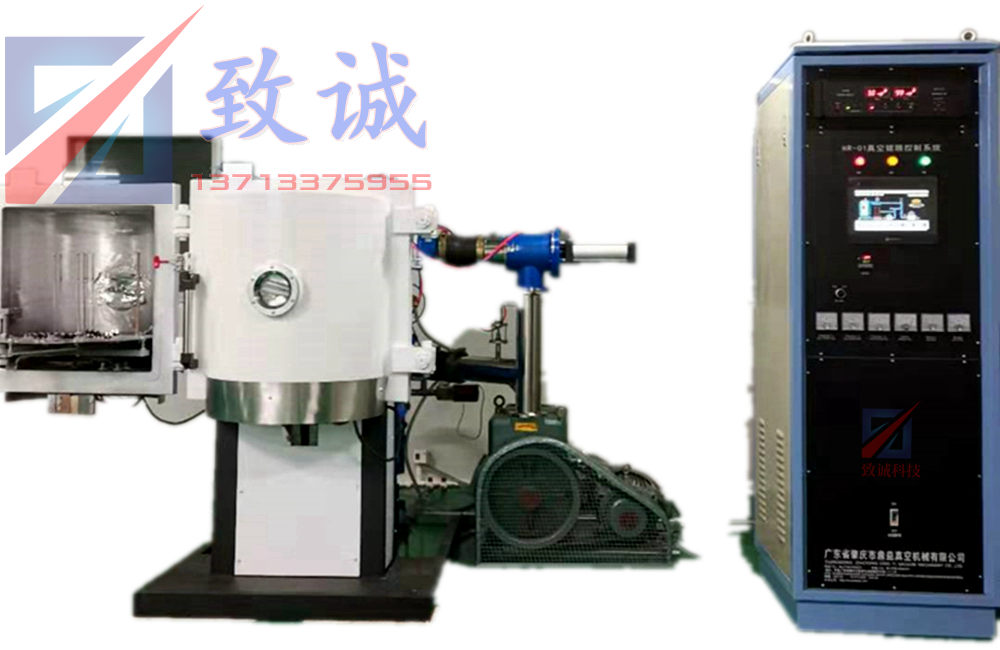

Horizontal evaporation coating machine

Vacuum coating machine for lamps

AF anti-fingerprint coating machine

PVD aluminum mirror coating machine

Vacuum internal plating equipment - evaporation coating machine - plastic/glass lampshade

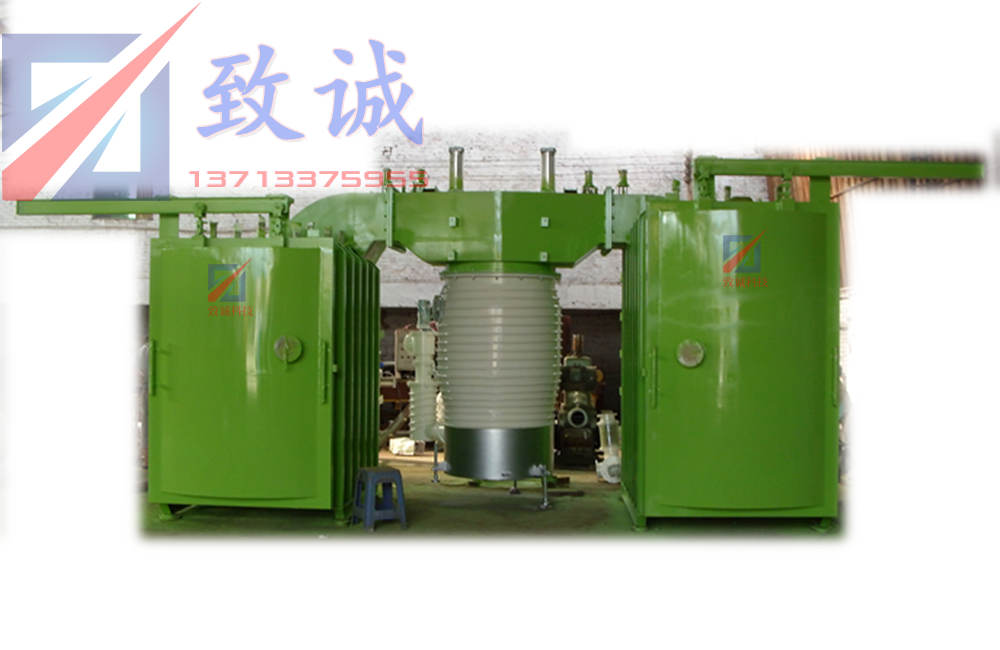

Magnetic control evaporation dual-purpose coating machine

Laboratory coating equipment

Dongguan City, Guangdong Province, China

+86 137-1337-5955

+86 13713375955 (Mr. Deng)

dgzhicheng@gmail.com

Copyright © 2022 Dongguan Zhicheng Technology Co., Ltd.