Server-Online

137-1337-5955

13713375955

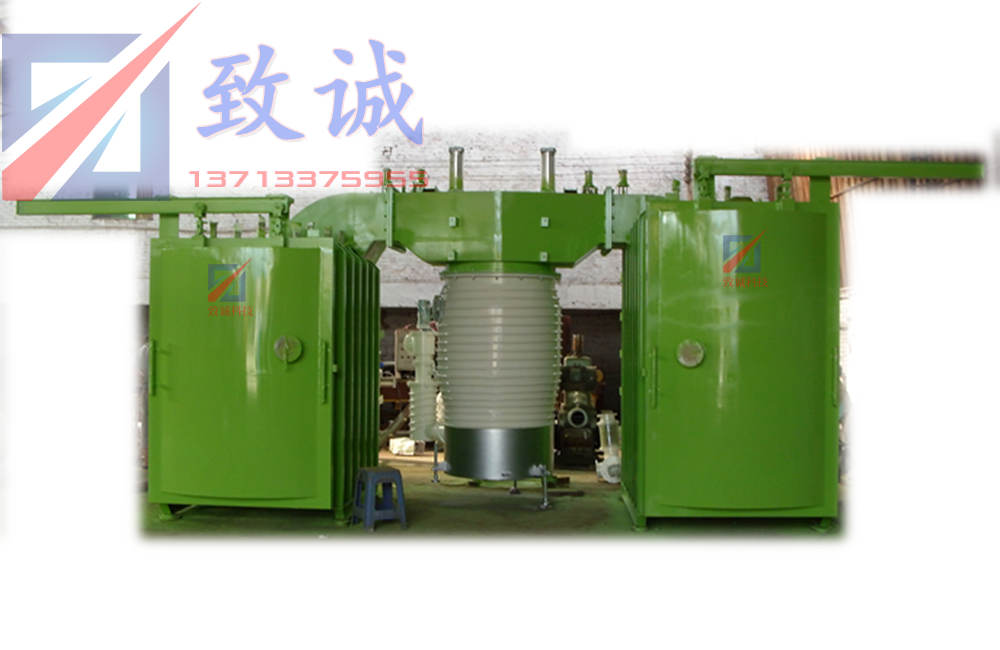

Vertical double-door-high vacuum evaporation coating machine

PVD aluminum mirror coating machine

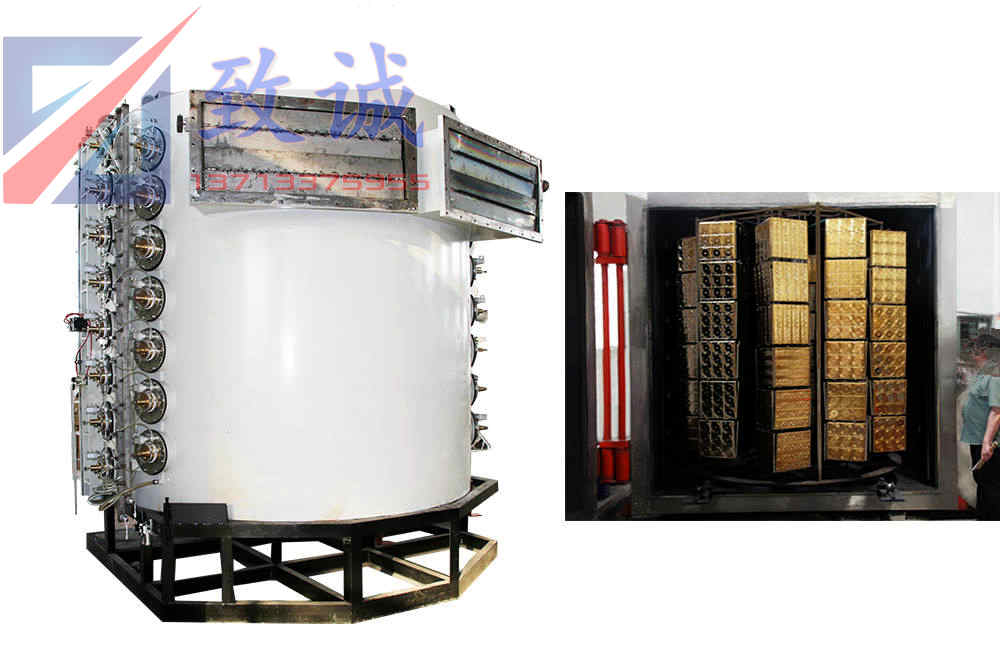

Multi-arc ion coating machine for hardware

Intermediate frequency ion coating machine

Glass special coating machine

Ceramic Vacuum Coating Machine

Large stainless steel coating machine

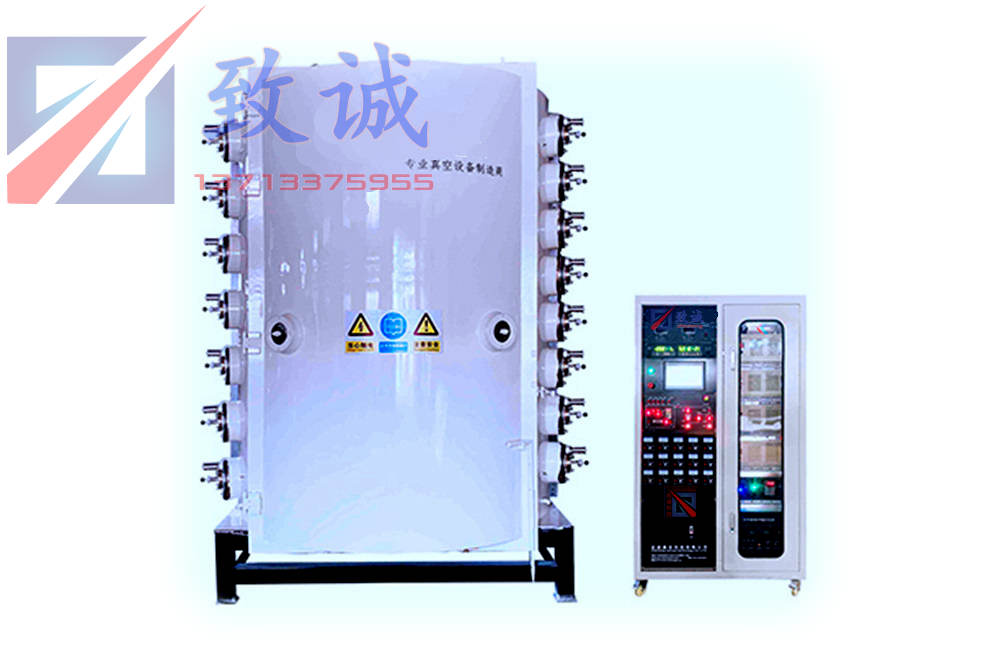

DC magnetron sputtering coating equipment

ABOUT ZHICHENG

Zhicheng vacuum coating equipment

Vacuum equipment solution

Zhicheng Vacuum application solutions

Industry-leading vacuum Application Solutions

Service Line: +86 13713375955

Service Line: +86 13713375955

Plastic Metallization - High Vacuum Evaporation Coating

Symphony/Colorful Plating-Vacuum Coating Equipment-Evaporation Coating Machine

PVD Vacuum Coating Equipment_Intermediate Frequency Ion Coating Machine_Hardware Vacuum Plating Equipment

Технология гальванического покрытия ступиц колес автомобилей и мотоциклов_Оборудование для вакуумных покрытий_Процесс магнетронного напыления

Vacuum evaporation coating machine_plastic metallization UV electroplating processing technology

Cosmetic Shell Electroplating_Evaporation Coating Machine_PVD Vacuum Coating Equipment

Automobile and motorcycle electroplating, refurbishment, repair and modification__Wheel hub magnetron sputtering vacuum coating machine

Ion Coating Machine-Metal/Ceramic/Glass

Vacuum coating machine coating technology industry application

Replacing the traditional electroplating process with vacuum coating technology can not only save a lot of film materials and reduce energy consumption, but also eliminate environmental pollution caused by wet coating. Therefore, foreign countries have adopted vacuum coating process to replace electroplating process in terms of coating anti-corrosion layer and protective film on steel parts.

272023-03

How to maintain the vacuum coating machine When the buyer purchases the vacuum coating machine, the manufacturer Shengchang equipment will generally be equipped with a machine maintenance manual. Both the buyer and the manufacturer attach great importance to the maintenance of the vacuum coating machine.

112023-03

Why does the evaporation coating machine coat under vacuum conditions If the pressure is not low enough (or the vacuum degree is not high enough), good results cannot be obtained. For example, if aluminum is deposited on the order of 10 2 Torr, the obtained film is not only not bright, but even gray and black. And the mechanical strength is extremely poor.

112023-03

What is the difference between PVD vacuum coating machine and CVD coating machine? Thin film deposition technology is mainly divided into three major processes: physical, chemical, and epitaxy. Physical vapor deposition is referred to as PVD vacuum coating machine. Chemical vapor deposition is referred to as CVD coating machine for short.

032023-03

Vacuum conditions in the process of vacuum evaporation coating machine In the vacuum chamber, when the particle concentration in the gas phase and the pressure of the residual gas are low enough, these particles can keep flying in a straight line from the evaporation source to the substrate, otherwise, they will collide and change the direction of motion.

022023-03

Common problems of PVD evaporation process and sputtering process Vacuum coating equipment uses two common coating processes, evaporation and sputtering. These two processes are currently the most popular and widely used, and their attention is naturally much higher than other processes.

022023-03

Development and Application of Coating Technology for Ion Plating Equipment Vacuum multi-arc ion coating machine technology Titanium plating is a process for surface treatment of metal materials. It has been widely used in the industrial field and has the intention to gradually promote it.

Dongguan City, Guangdong Province, China

+86 137-1337-5955

+86 13713375955 (Mr. Deng)

dgzhicheng@gmail.com

Copyright © 2022 Dongguan Zhicheng Technology Co., Ltd.