Server-Online

137-1337-5955

13713375955

There are two common coating processes for vacuum coating machines, evaporation and sputtering. These two processes are currently the most popular and widely used. Then, naturally, their attention is much higher than that of other processes.

ZhichengTechnology has summarized four frequently asked questions about the two processes of vacuum coating machines in detail.

1. Why can vacuum coating be made into different colors, and there are seven colors?

Because a layer of UV varnish topcoat is sprayed after vacuum evaporation, and different colors can be made on this topcoat. Evaporation can be made into seven colors by plating some silicides, but it is relatively thin. Layers of coatings of different colors to present colorful.

2. What is the reason for the difference in adsorption between vacuum evaporation and vacuum sputtering?

Evaporation is adhesion, and sputtering is strong adsorption of positive and negative electrodes, so the sputtering adsorption is more uniform, denser and harder, and the price of sputtering is 10%-20% more expensive than evaporation.

3. Why can vacuum coating be made semi-transparent and non-conductive?

It is not completely non-conductive, and the discontinuity of molecules in the thin film state is used. Metals or metal compounds are conductive, but the conductivity is different. However, when the metal or metal compound is in the state of a thin film, the corresponding physical properties are different. Among the conventional coating materials, for example: silver is the metal with the best silver-white effect and conductivity, but when its thickness is below 5 nanometers, it is non-conductive; the silver-white effect and conductivity of aluminum are slightly worse than silver, but it When the thickness is 0.9 nanometers, it is already conductive. Why is this so? That's because the continuity of silver molecules is not as good as that of aluminum, so its conductivity is poorer under the relative film thickness. Our vacuum-plated metal non-conductive film actually uses the principle of poor molecular continuity of certain metals to control its thickness within a certain range, making it have a silver-white appearance and high resistance. It can be seen that the effect of the metal non-conductive film is directly related to its film thickness. Only under the corresponding film thickness can a correspondingly stable silver-white non-conductive film be obtained.

As mentioned above, silver with the best silver-white effect and conductivity is non-conductive when the thickness is less than 5 nanometers. So, can silver be used to make the metal non-conductive film we need? the answer is negative. Because silver with a thickness of less than 5 nanometers is basically transparent and colorless, although it is not conductive, it cannot have the effect of a silver-white reflective film at the same time. Likewise, aluminum won't work either. Therefore, we need a metal material that can be plated with a silver-white metallic luster and has a large resistance. We use tin or indium and indium-tin alloys with a purity of more than 99.99%. Tin with a thickness of less than 30 nanometers has poor continuity, but it can obtain a silvery white metallic luster and have greater resistance. The same is true for indium, but the silver-white reflectance of indium is better than the appearance of tin, because the price is higher, we use indium-tin alloy, so that we can get a non-conductive film and a whiter and brighter reflective metal effect! The indium-tin-plated non-conductive film is translucent, so we require the substrate to be plated to be transparent or black. Because indium tin plating starts to melt at 250 degrees, the evaporation temperature is relatively low, so the current and time for heating, melting and evaporation are relatively low.

4. Why is the aluminum plating of vacuum coating not conductive?

Because the coating has a total of three layers, the outermost layer of UV varnish acts as a curing wear-resistant insulation after UV irradiation, but once this layer of film is destroyed, it will conduct electricity.

Vacuum coating machine evaporation coating process, sputtering coating process, not only these four common problems, but they are the most common and the most concerned four problems.

How to maintain the vacuum coating machine

2023-03-27

How to maintain the vacuum coating machine

2023-03-27

When the buyer purchases the vacuum coating machine, the manufacturer Shengchang equipment will generally be equipped with a machine maintenance manual. Both the buyer and the manufacturer attach great importance to the maintenance of the vacuum coating machine.

Why does the evaporation coating machine coat under vacuum conditions

2023-03-11

Why does the evaporation coating machine coat under vacuum conditions

2023-03-11

If the pressure is not low enough (or the vacuum degree is not high enough), good results cannot be obtained. For example, if aluminum is deposited on the order of 10 2 Torr, the obtained film is not only not bright, but even gray and black. And the mechanical strength is extremely poor.

What is the difference between PVD vacuum coating machine and CVD coating machine?

2023-03-11

What is the difference between PVD vacuum coating machine and CVD coating machine?

2023-03-11

Thin film deposition technology is mainly divided into three major processes: physical, chemical, and epitaxy. Physical vapor deposition is referred to as PVD vacuum coating machine. Chemical vapor deposition is referred to as CVD coating machine for short.

Vacuum conditions in the process of vacuum evaporation coating machine

2023-03-03

Vacuum conditions in the process of vacuum evaporation coating machine

2023-03-03

In the vacuum chamber, when the particle concentration in the gas phase and the pressure of the residual gas are low enough, these particles can keep flying in a straight line from the evaporation source to the substrate, otherwise, they will collide and change the direction of motion.

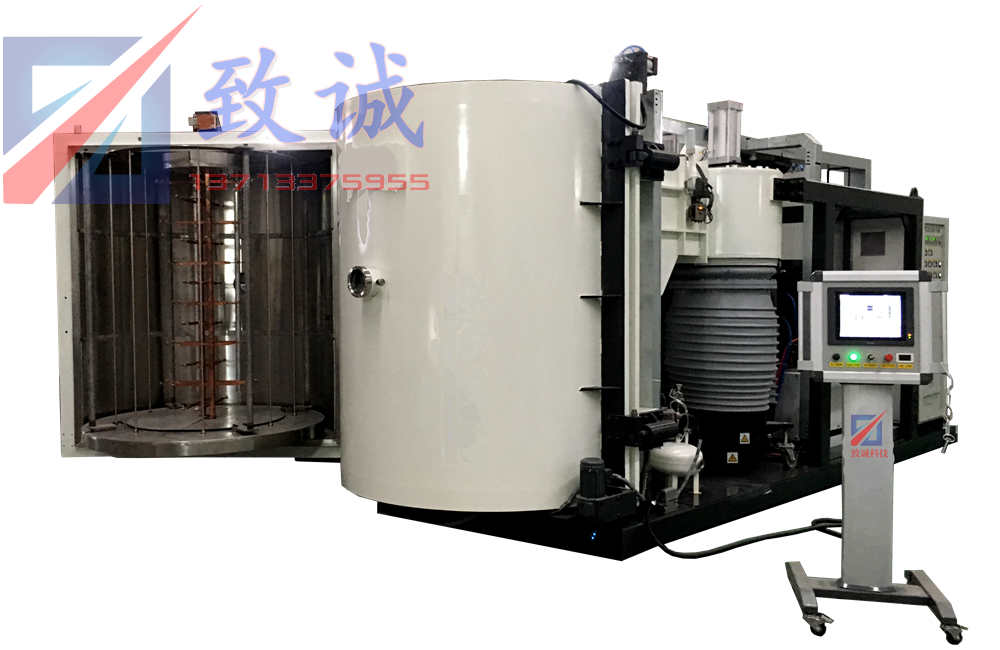

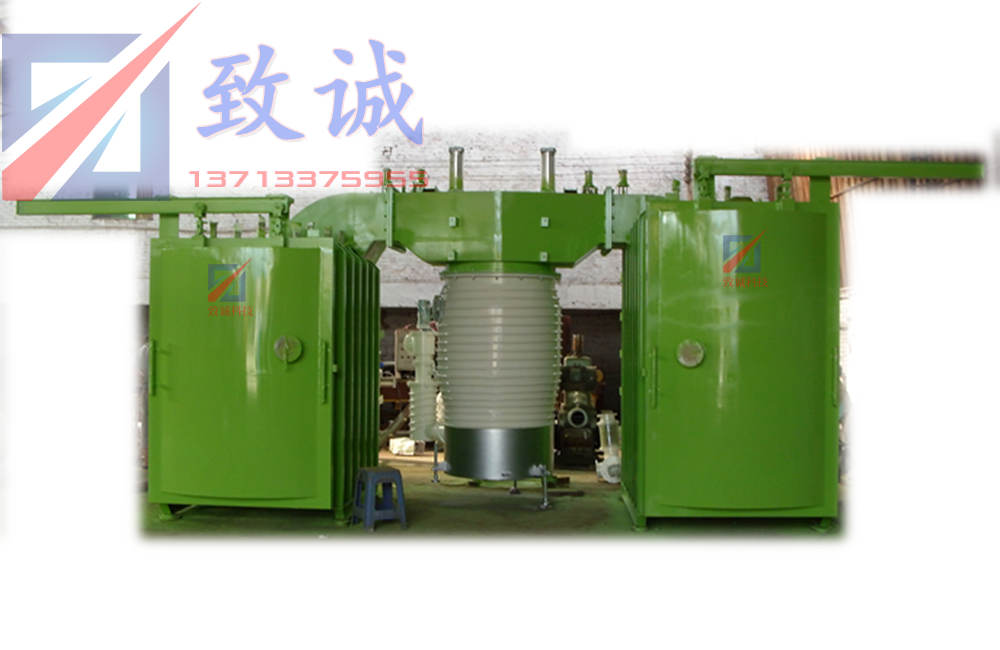

Vertical double-door-high vacuum evaporation coating machine

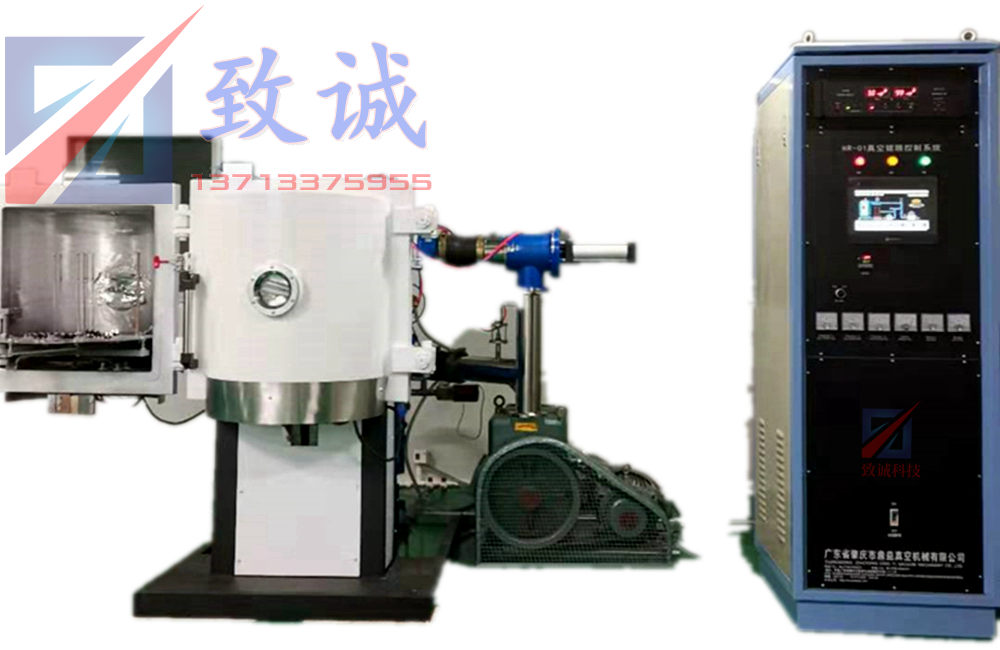

Horizontal evaporation coating machine

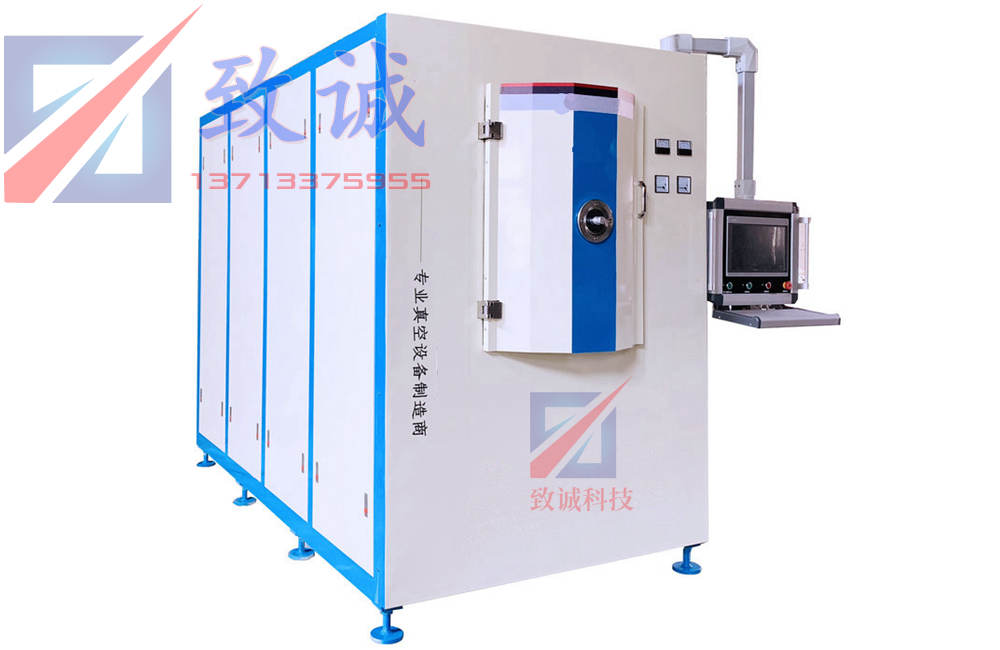

Vacuum coating machine for lamps

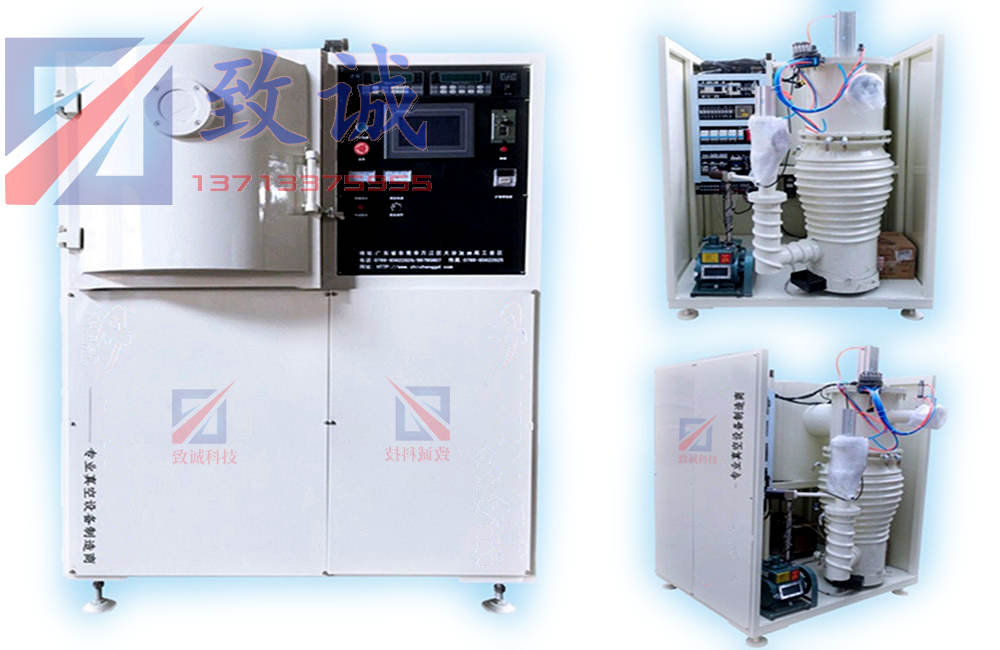

AF anti-fingerprint coating machine

PVD aluminum mirror coating machine

Vacuum internal plating equipment - evaporation coating machine - plastic/glass lampshade

Magnetic control evaporation dual-purpose coating machine

Laboratory coating equipment

Dongguan City, Guangdong Province, China

+86 137-1337-5955

+86 13713375955 (Mr. Deng)

dgzhicheng@gmail.com

Copyright © 2022 Dongguan Zhicheng Technology Co., Ltd.