Server-Online

137-1337-5955

13713375955

When I first learned about or just came into contact with the vacuum coating machine industry, many people were curious why the evaporation material of the vacuum coating equipment must be in a vacuum state, and the vacuum coating must meet certain standards. The following details:

The ideal film cannot be formed by evaporating the film material under normal pressure. In fact, if the pressure is not low enough (or the vacuum degree is not high enough), good results will not be obtained, such as evaporating aluminum on the order of 10 2 Torr , the obtained film layer is not only not bright, but even gray and black, and its mechanical strength is extremely poor. The aluminum layer can be destroyed by lightly brushing with a squirrel hair brush.

Evaporation must be carried out under certain vacuum conditions because:

1,

A higher vacuum can ensure that the mean free path of vaporized molecules is greater than the distance from the evaporation source to the substrate. Due to the thermal motion of gas molecules, the collisions between molecules are also extremely frequent, so although the speed of gas molecules is quite high (up to hundreds of meters per second), because it has to interact with other molecules in the process of advancing The distance traveled by a molecule between two consecutive collisions is called its free path, and the statistical average of the free paths of a large number of molecules is called the mean free path of the molecule.

Since the gas pressure is proportional to the number of molecules per unit volume, the mean free path is also proportional to the gas pressure. In the process of vacuum deposition of thin films, when the deposition distance is greater than the mean free path of molecules, it is called low vacuum deposition, and when the deposition distance is smaller than the mean free path of molecules, it is called high vacuum deposition. During high vacuum deposition, the collision between evaporated atoms (or molecules) and residual gas molecules is negligible, so the evaporated atoms fly to the substrate along a straight line, so that the evaporated atoms that maintain a large kinetic energy and reach the substrate can be Condensate into a firmer film on the substrate. During low-vacuum deposition, the speed and direction of vaporized atoms will change due to collisions, and even aggregates of steam atoms may be generated in space—the reason is similar to the fog generated by water vapor in the atmosphere.

2,

Residual gas pollution can be reduced under high vacuum. When the vacuum is not too high, there are many residual gas molecules (oxygen, nitrogen, water and hydrocarbons, etc.) in the vacuum chamber, which can affect the coating of the film. would cause great harm. They collide with vaporized film material molecules to shorten the mean free path; they collide with and react with the surface being filmed; they hide in the formed film and gradually erode the film; they combine with the evaporation source at high temperature to reduce its service life ; They form an oxide layer on the surface of the evaporated film material so that the evaporation process cannot be carried out smoothly.

Therefore, the evaporative vacuum coating machine must coat the film layer, and the film must be coated in a vacuum state, so that the film layer will be firm and there will be no pollutants.

How to maintain the vacuum coating machine

2023-03-27

How to maintain the vacuum coating machine

2023-03-27

When the buyer purchases the vacuum coating machine, the manufacturer Shengchang equipment will generally be equipped with a machine maintenance manual. Both the buyer and the manufacturer attach great importance to the maintenance of the vacuum coating machine.

Why does the evaporation coating machine coat under vacuum conditions

2023-03-11

Why does the evaporation coating machine coat under vacuum conditions

2023-03-11

If the pressure is not low enough (or the vacuum degree is not high enough), good results cannot be obtained. For example, if aluminum is deposited on the order of 10 2 Torr, the obtained film is not only not bright, but even gray and black. And the mechanical strength is extremely poor.

What is the difference between PVD vacuum coating machine and CVD coating machine?

2023-03-11

What is the difference between PVD vacuum coating machine and CVD coating machine?

2023-03-11

Thin film deposition technology is mainly divided into three major processes: physical, chemical, and epitaxy. Physical vapor deposition is referred to as PVD vacuum coating machine. Chemical vapor deposition is referred to as CVD coating machine for short.

Vacuum conditions in the process of vacuum evaporation coating machine

2023-03-03

Vacuum conditions in the process of vacuum evaporation coating machine

2023-03-03

In the vacuum chamber, when the particle concentration in the gas phase and the pressure of the residual gas are low enough, these particles can keep flying in a straight line from the evaporation source to the substrate, otherwise, they will collide and change the direction of motion.

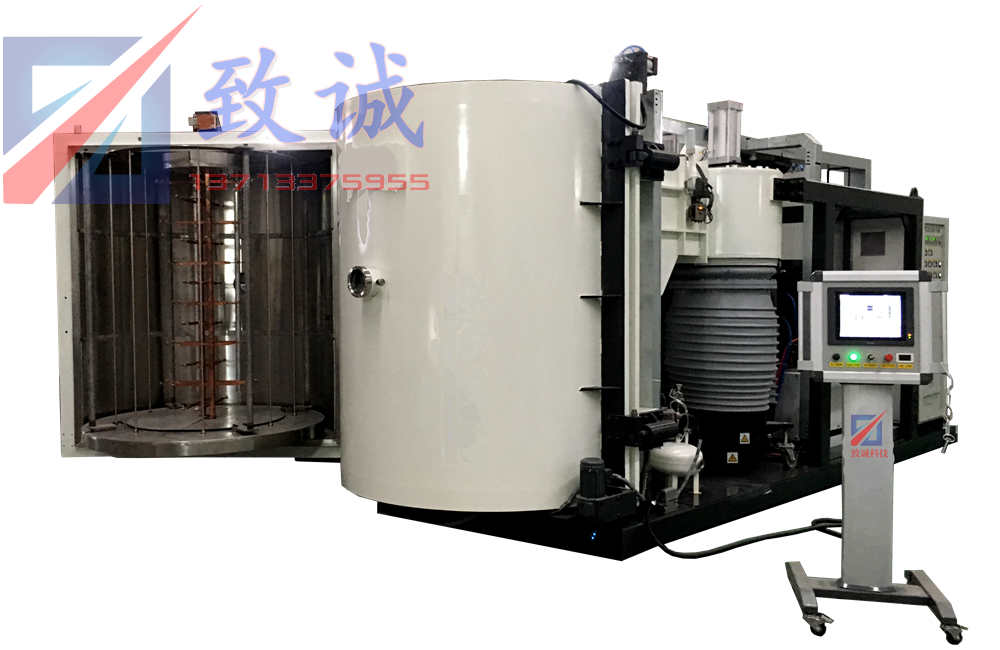

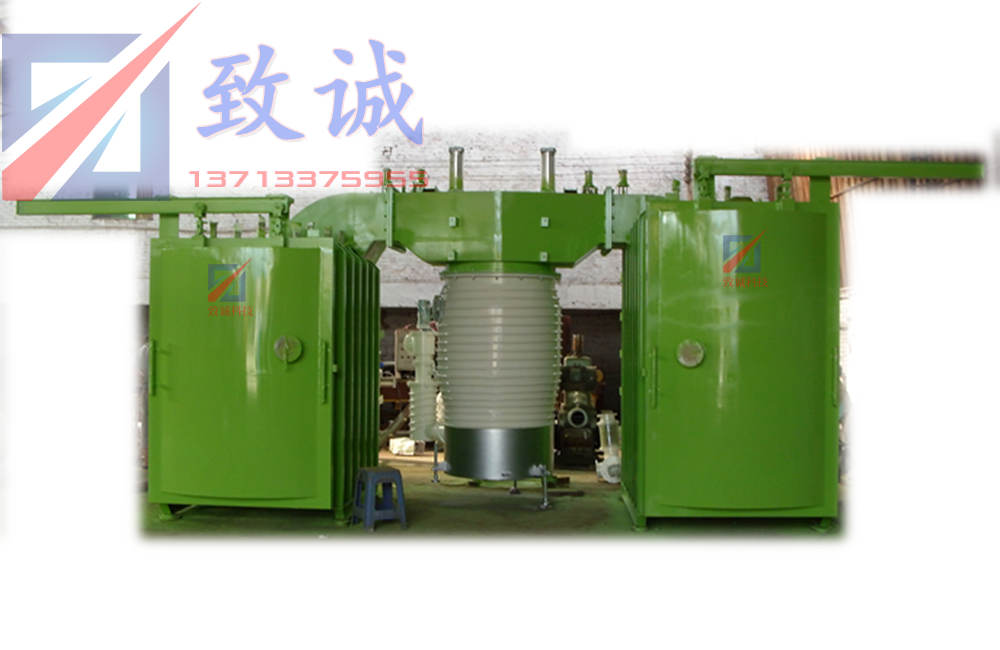

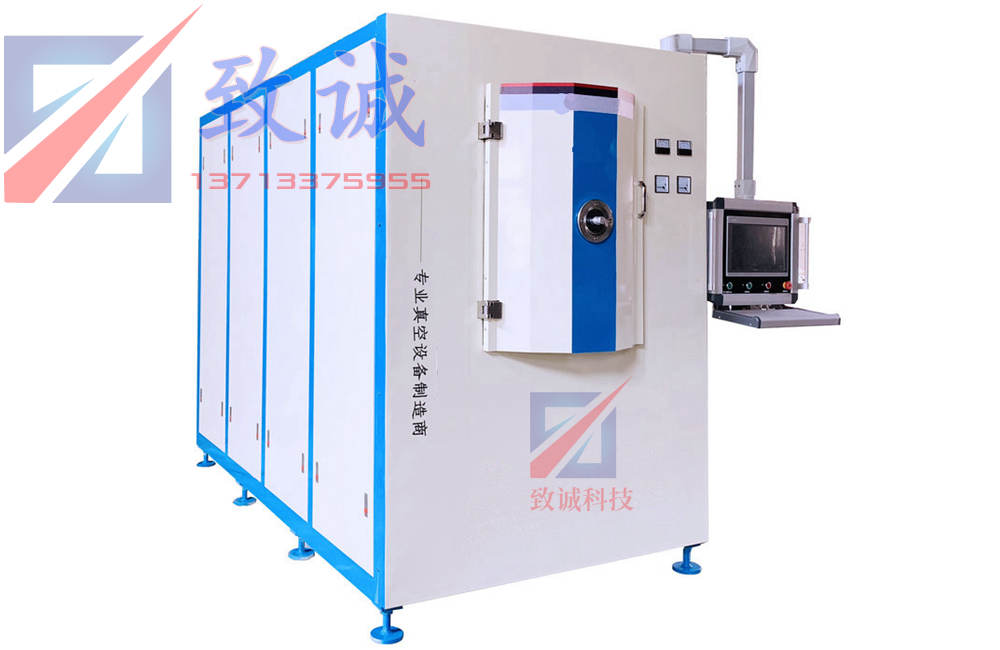

Vertical double-door-high vacuum evaporation coating machine

Horizontal evaporation coating machine

Vacuum coating machine for lamps

PVD aluminum mirror coating machine

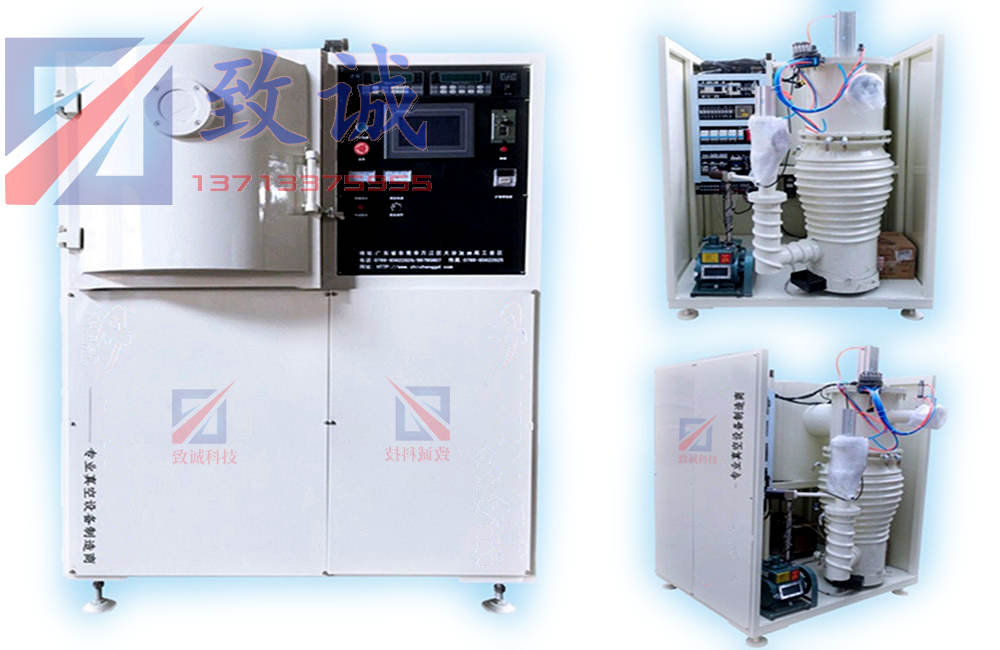

AF anti-fingerprint coating machine

Vacuum internal plating equipment - evaporation coating machine - plastic/glass lampshade

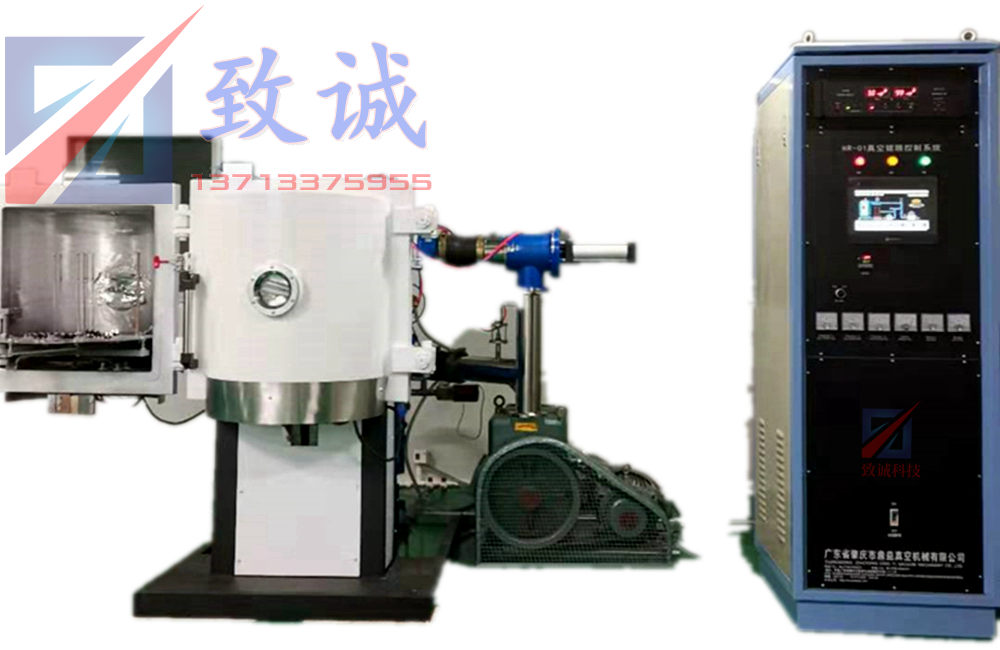

Magnetic control evaporation dual-purpose coating machine

Laboratory coating equipment

Dongguan City, Guangdong Province, China

+86 137-1337-5955

+86 13713375955 (Mr. Deng)

dgzhicheng@gmail.com

Copyright © 2022 Dongguan Zhicheng Technology Co., Ltd.