Server-Online

137-1337-5955

13713375955

The installation and commissioning stage is the main body of the leak detection work of the vacuum coating machine. If the airtightness of the weld seam of the equipment has been guaranteed through the leak detection in the processing stage, then in the process of equipment installation and commissioning, checking and ensuring the tightness of the connection parts is the focus of the leak detection work. Including key suspicious parts such as various pipelines, flange connections between components, and dynamic seals. If leak detection is performed on the weld seam and the joint at the same time, the workload and difficulty of leak detection will increase. For large and complex vacuum equipment, it is best to use segmental leak detection. Each time a component is installed, a leak detection is performed on its connection parts and welds, and the next component is installed after meeting the requirements. Because after all the components are fully assembled, there are not only too many suspected parts, but also multiple leaks may leak at the same time, which brings great difficulties to the overall leak detection.

The leak detection steps during the installation and commissioning of vacuum equipment are as follows:

1,

Understand the structural composition and assembly process of the equipment to be inspected. Master the requirements of the equipment, and find out the key suspicious parts that need to be leak tested.

2,

According to the specified maximum allowable leak rate and whether it is necessary to find the specific location of the leak hole, etc., and proceed from the principles of economy, speed, and reliability, correctly select the leak detection method or instrument, and prepare the auxiliary equipment required for leak detection. Then develop a practical leak detection program.

3.

The inspected parts should be cleaned well, and the welding slag and oil dirt should be removed, and then cleaned according to the vacuum sanitation conditions, and dried. For demanding small devices. After cleaning, it can be baked in a vacuum drying oven. After cleaning, it can not only prevent the leak from being blocked by dirt, oil, organic solution, etc., but also protect the leak detection instrument.

4.

Calibrate the leak detection sensitivity of the selected leak detection method and leak detection equipment, and determine the leak detection time of the leak detection system.

5.

If the vacuum leak detection method is used, in order to improve the sensitivity of the instrument, the tested part should be pumped to a higher vacuum as much as possible.

6.

Under the premise of permission, the more economical and on-site leak detection methods should be given priority as much as possible.

7.

When using helium mass spectrometer leak detection equipment for leak detection, for the inspected parts that require low leak detection or have large leaks, try to use helium with a lower concentration for leak detection at the initial stage of leak detection, and then conduct small leaks. Leak detection of holes to save helium.

8,

Repair and block the large leaks that have been detected in time, and then carry out leak detection for small leaks.

9,

Conduct a re-examination of the detected and repaired leaks to ensure that the leak detection results meet the requirements.

The leak detection link of the vacuum coating machine is a step that needs to be carried out in all links from design, manufacture, commissioning, use, etc., and it is absolutely necessary.

What is the difference before and after the workpiece is plated by the vacuum coating machine?

2023-03-11

What is the difference before and after the workpiece is plated by the vacuum coating machine?

2023-03-11

Vacuum coating machines are widely used in various industries, including machinery, electronics, hardware, aerospace, medical, chemical and other fields.

Vacuum coating machine design should pay attention to details

2023-03-03

Vacuum coating machine design should pay attention to details

2023-03-03

In order to ensure that the vacuum coating machine has good sealing performance, it is necessary to cut off the cause of possible leaks at the source

How to check for leaks during installation and commissioning of vacuum coating machine

2023-03-03

How to check for leaks during installation and commissioning of vacuum coating machine

2023-03-03

The leak detection link of the vacuum coating machine is a step that needs to be carried out in all links from design, manufacture, commissioning, use, etc., and it is absolutely necessary.

Vacuum coating machine sputtering sputtering process introduction

2023-03-03

Vacuum coating machine sputtering sputtering process introduction

2023-03-03

The sputtering method can be used to prepare material films with high melting point and low vapor pressure that cannot be prepared by the evaporation process, which is convenient for the preparation of thin films of compounds or alloys. The vacuum coating machine sputtering sputtering process is mainly used for sputtering etching and film deposition. .

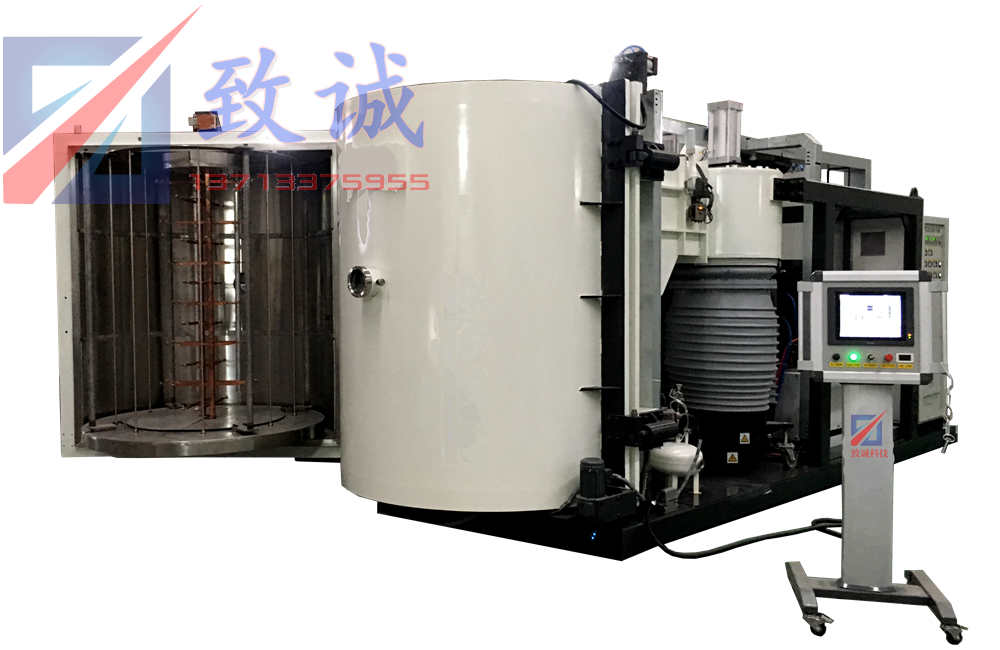

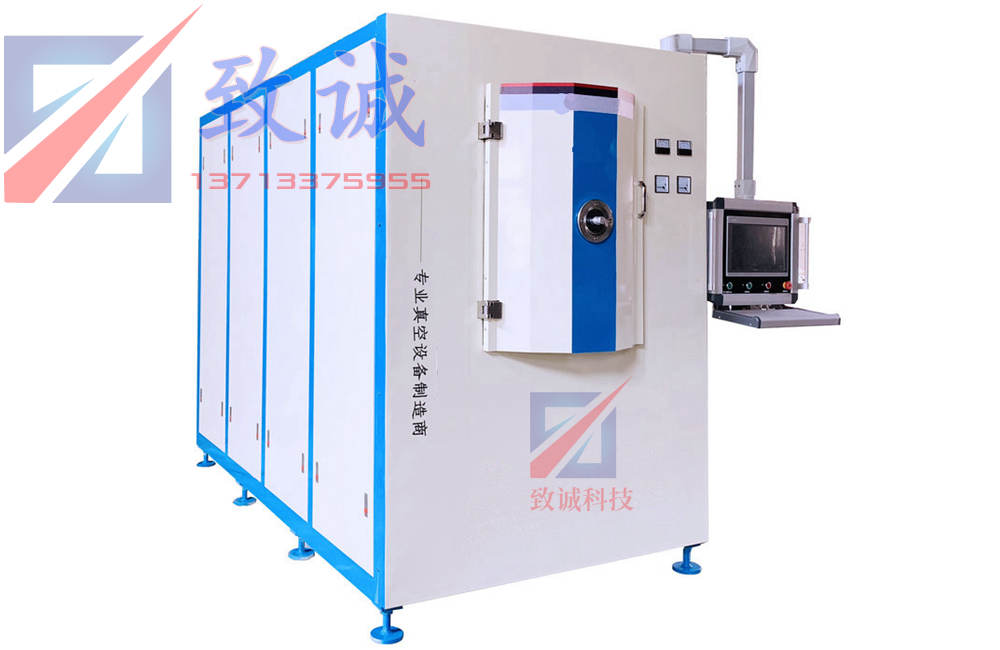

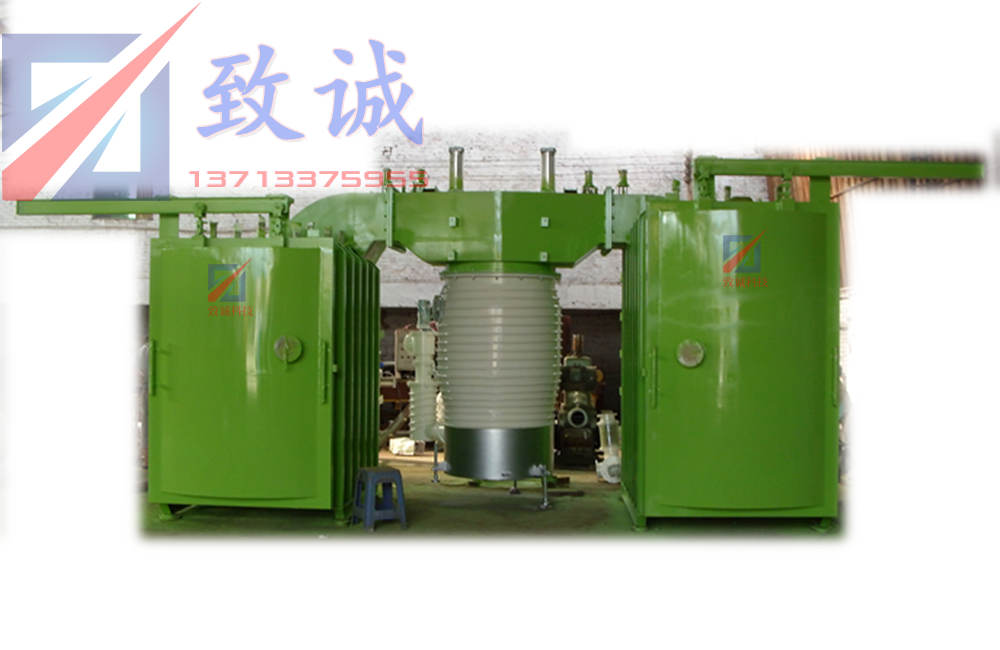

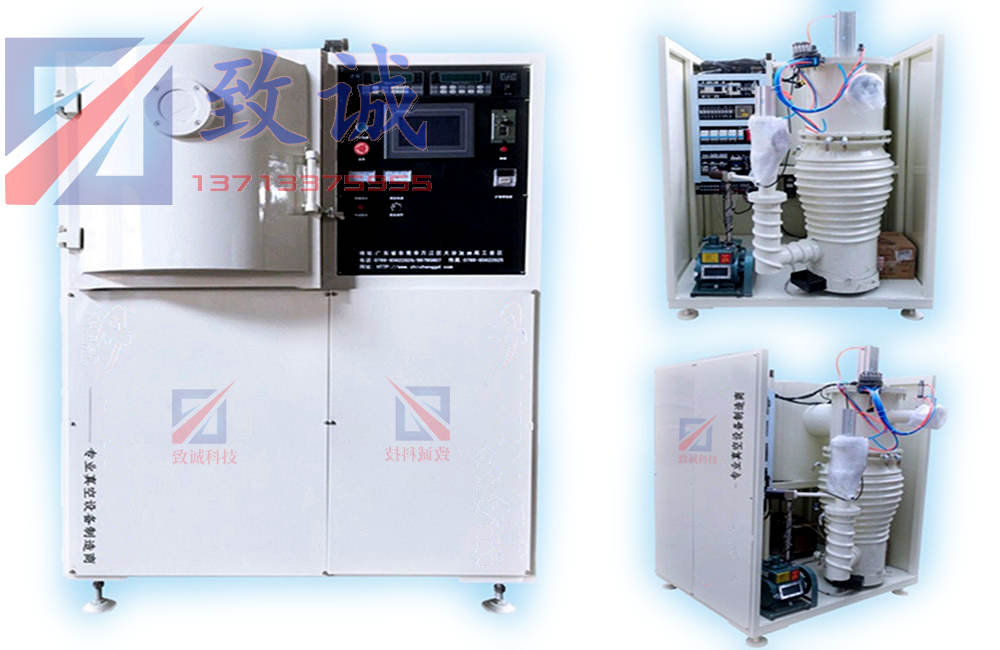

Vertical double-door-high vacuum evaporation coating machine

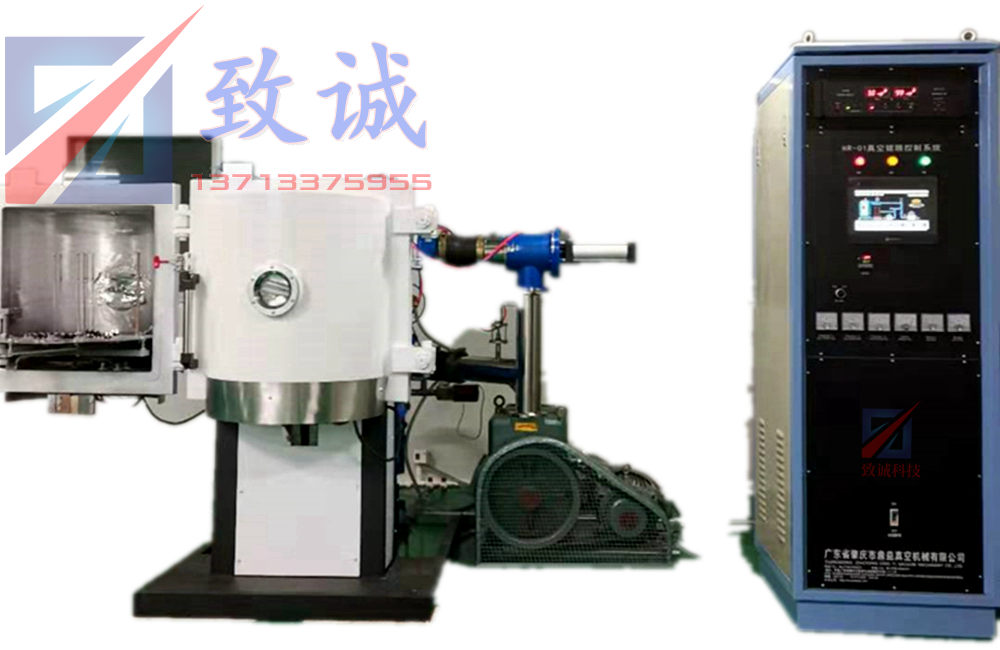

Horizontal evaporation coating machine

Vacuum coating machine for lamps

AF anti-fingerprint coating machine

PVD aluminum mirror coating machine

Vacuum internal plating equipment - evaporation coating machine - plastic/glass lampshade

Magnetic control evaporation dual-purpose coating machine

Laboratory coating equipment

Dongguan City, Guangdong Province, China

+86 137-1337-5955

+86 13713375955 (Mr. Deng)

dgzhicheng@gmail.com

Copyright © 2022 Dongguan Zhicheng Technology Co., Ltd.