Server-Online

137-1337-5955

13713375955

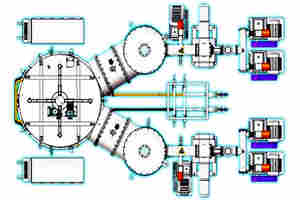

Vacuum coating machines can be classified according to industries, such as lens vacuum coating machines, electronic product coating machines, optical filter coating machines, etc., all belong to optical coating machines, such as packaging vacuum coating machines, anti-counterfeiting vacuum coating machines, capacitor winding vacuum coating machines And so on belong to the winding coating machine. Such as multi-arc ion vacuum coating machine, hardware decoration vacuum coating machine, high vacuum evaporation coating machine, ceramic tile vacuum coating machine, belonging to decorative ion coating machine.

However, many people will also classify according to the function of the vacuum furnace. Zhicheng Vacuum will introduce it in detail:

Vacuum coating machine

According to the thin film principle, it can be divided into sputtering coating, ion coating, evaporation coating and chemical vapor deposition coating. According to the purpose of application, it can be divided into optical coating, winding coating, decorative coating, solar heat collector coating, tool coating, architectural coating, conductive coating and so on.

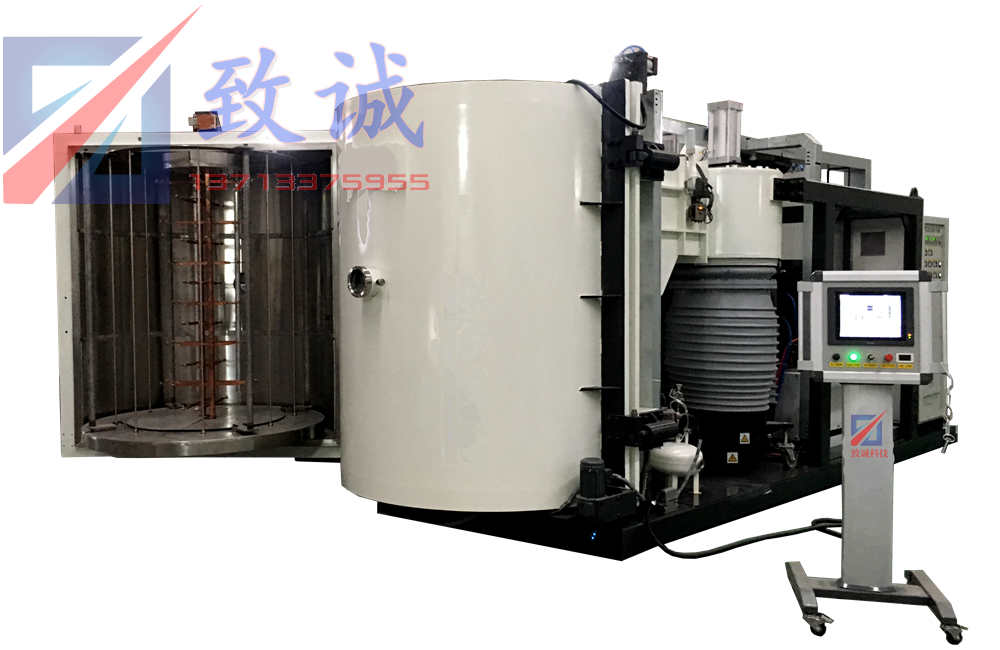

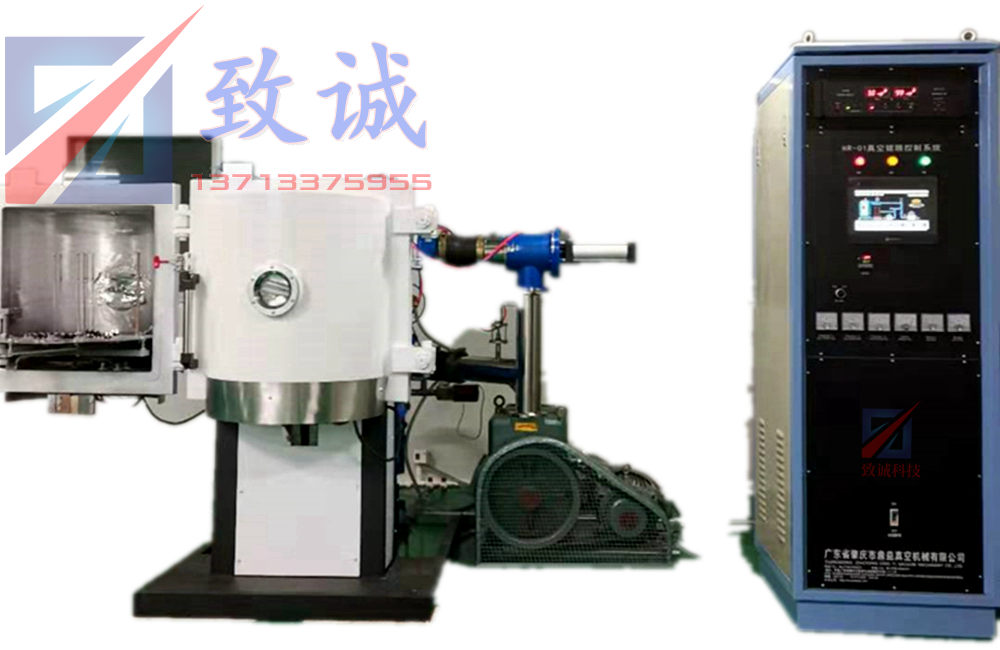

Vacuum Evaporation Coating Machine

Evaporation coating equipment is the first coating equipment successfully developed among all coating equipment in China. It has been successfully developed in China in the 1950s. There are many types of evaporation coating equipment, including optical coating equipment for coating optical films, mainly used for Optical equipment, laser equipment, microelectronic equipment, etc., as well as coil coating equipment made of the principle of transpiration coating, are used in various industries such as decoration and electronic equipment packaging.

Sputter Coater

The ion target is sputtered out and deposited on the substrate to form a thin film. Sputtering coating equipment can coat various thin films such as ITO conductive film, dielectric film, semiconductor film, metal film, magnetic film, high-temperature superconducting film, single crystal film, and decoration film, such as large-scale integrated circuits and optical discs in the electronic industry , Plating of disk film. It is used in curtain wall glass films in the construction industry, capacitor films in the electronics industry, solid smooth films in aerospace vehicles, solar cells in power, and many industries such as gas, packaging, and infrared technology.

Ion coating machine

Ion coating equipment can be divided into arc ion coating, radio frequency discharge ion coating, hollow cathode ion coating, etc. Ion plating is characterized by fast deposition speed, dense coating quality and good film adhesion due to its coating principle. It is widely used in tools, molds and other industries, and can be coated with metal film, hard film, imitation gold film and so on.

Chemical Vapor Deposition Equipment

Chemical vapor deposition equipment is used to form films by chemical reactions, which can be used to coat surface protective films, semiconductors and electronic materials.

Ion Beam Etching Equipment

As an ultra-fine processing technology in the semiconductor industry, etching has become an indispensable and important equipment with the increase in the integration of large-scale integrated circuits. Compared with other chemical etching, plasma sputtering and other technologies, ion beam etching technology has no selectivity for processing materials, can perform ultra-fine processing, and can etch very fine grooves. The etched graphics have clear edges and high precision. . Ion beam etching equipment can be divided into vertical type and horizontal type. The vacuum system of domestic equipment is mainly based on oil dispersion pump and water-cooled baffle, while cryopump pumping system is mostly used abroad.

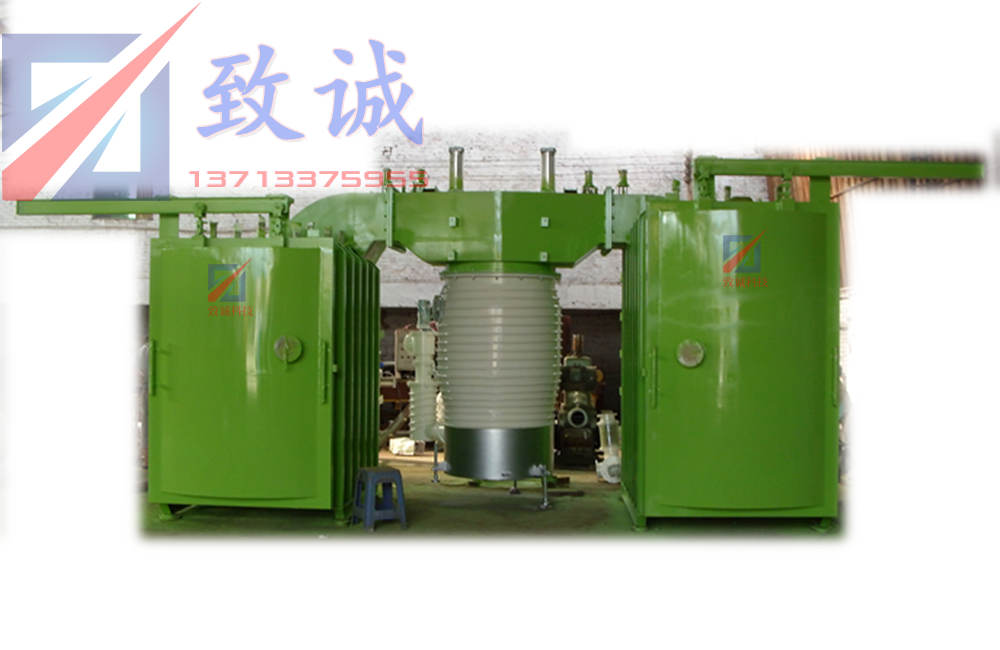

vacuum furnace

The development of vacuum furnaces in China began in the late 1950s. The first 10kg vacuum induction furnace was developed in Shenyang in 1958 and passed the appraisal in 1960. At present, there are many kinds of vacuum furnaces produced in China, which can be roughly divided into metallurgical furnaces and heat treatment furnaces. Metallurgical furnaces include: vacuum resistance furnaces, vacuum sintering furnaces, vacuum electric arc furnaces, vacuum induction furnaces, single crystal furnaces, and vacuum brazing equipment. ; Vacuum heat treatment furnace includes: vacuum quenching furnace, tempering furnace, annealing furnace, carburizing furnace, glow ion nitriding furnace, etc.

Vacuum resistance furnace

The vacuum resistance furnace uses resistance to heat workpieces or materials under vacuum conditions. It is mainly used for annealing and vacuum degassing of vivid, insoluble metals or certain magnetic alloys. There are many types of resistance furnaces, which can be divided into vertical, horizontal, internal heating, external heating and so on according to different methods.

Vacuum sintering furnace

Vacuum sintering furnace is mainly used for sintering treatment of cemented carbide, ceramic materials, magnetic materials, rare refractory materials, metal powder products, photoelectric components and other materials. The information on sintering treatment is different. The types of vacuum sintering furnaces include high-temperature sintering furnaces that can reach above 2 000 ° C and high-vacuum sintering furnaces with higher vacuum degrees.

Vacuum arc furnace

The vacuum electric arc furnace uses the arc generated by arc discharge to melt the workpiece or material. It can be used for melting zirconium and refractory metals in combination with copper method. The types of vacuum electric arc furnaces can be divided into consumable furnaces, non-consumable furnaces and shell furnaces.

Vacuum induction furnace

The vacuum induction furnace uses electromagnetic induction to heat the crucible in the furnace, and melts metals and alloys in a vacuum state. It can melt fine alloys, magnetic materials, active metals and insoluble metals.

Vacuum coating machines are classified according to the function of vacuum furnace, and most of them are classified by industry. However, there are more classifications by industry units and vacuum furnaces.

What is the difference before and after the workpiece is plated by the vacuum coating machine?

2023-03-11

What is the difference before and after the workpiece is plated by the vacuum coating machine?

2023-03-11

Vacuum coating machines are widely used in various industries, including machinery, electronics, hardware, aerospace, medical, chemical and other fields.

Vacuum coating machine design should pay attention to details

2023-03-03

Vacuum coating machine design should pay attention to details

2023-03-03

In order to ensure that the vacuum coating machine has good sealing performance, it is necessary to cut off the cause of possible leaks at the source

How to check for leaks during installation and commissioning of vacuum coating machine

2023-03-03

How to check for leaks during installation and commissioning of vacuum coating machine

2023-03-03

The leak detection link of the vacuum coating machine is a step that needs to be carried out in all links from design, manufacture, commissioning, use, etc., and it is absolutely necessary.

Vacuum coating machine sputtering sputtering process introduction

2023-03-03

Vacuum coating machine sputtering sputtering process introduction

2023-03-03

The sputtering method can be used to prepare material films with high melting point and low vapor pressure that cannot be prepared by the evaporation process, which is convenient for the preparation of thin films of compounds or alloys. The vacuum coating machine sputtering sputtering process is mainly used for sputtering etching and film deposition. .

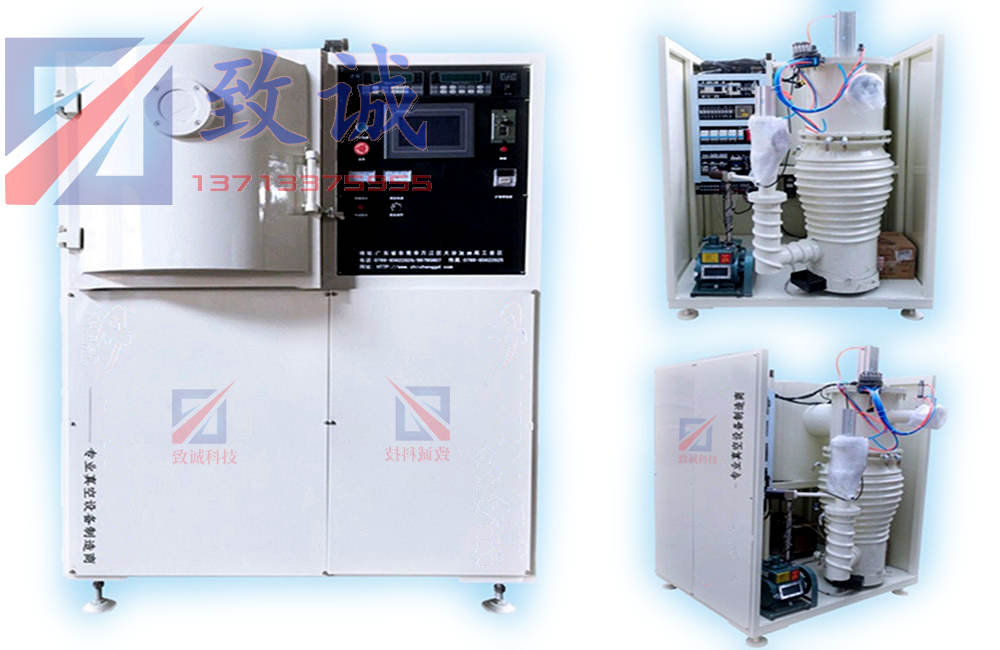

Vertical double-door-high vacuum evaporation coating machine

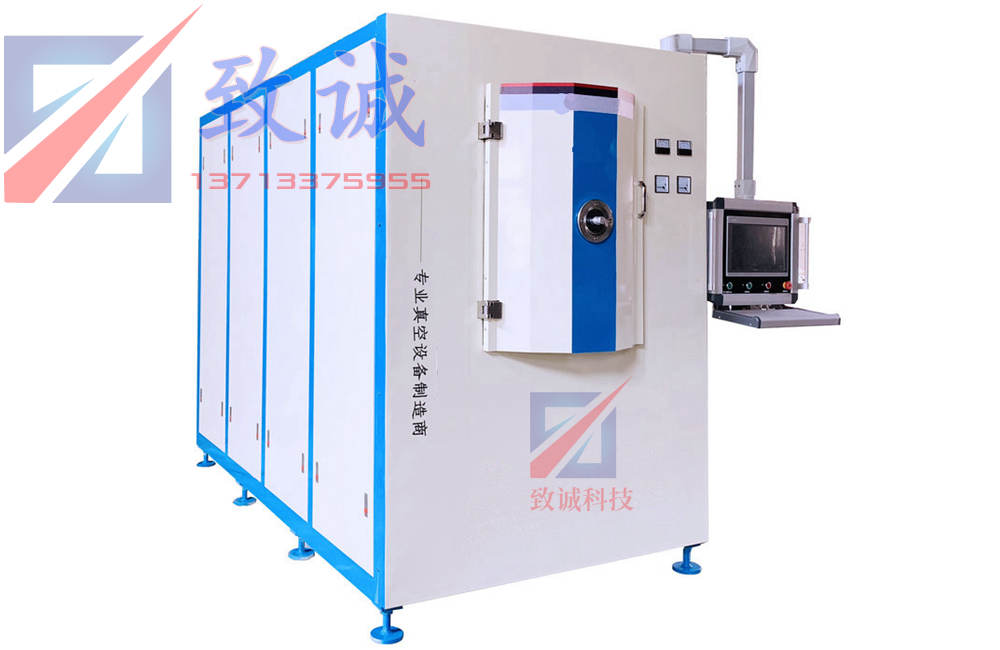

Horizontal evaporation coating machine

Vacuum coating machine for lamps

AF anti-fingerprint coating machine

PVD aluminum mirror coating machine

Vacuum internal plating equipment - evaporation coating machine - plastic/glass lampshade

Magnetic control evaporation dual-purpose coating machine

Laboratory coating equipment

Dongguan City, Guangdong Province, China

+86 137-1337-5955

+86 13713375955 (Mr. Deng)

dgzhicheng@gmail.com

Copyright © 2022 Dongguan Zhicheng Technology Co., Ltd.