Server-Online

137-1337-5955

13713375955

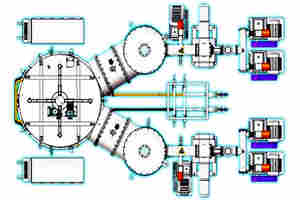

Vacuum coating machine sputtering sputtering process is mainly used in two aspects of sputtering etching and thin film deposition. During sputter etching, the material to be etched is placed at the target position and is bombarded by argon ions for etching. The etch rate is related to factors such as the sputtering yield of the target material, the ion current density and the vacuum degree of the sputtering chamber. During sputter etching, as much of the sputtered target atoms as possible should be removed from the sputtering chamber.

A common method is to introduce a reactive gas to react with the sputtered target atoms to generate a volatile gas, which is discharged from the sputtering chamber through a vacuum system. When depositing thin films, the sputtering source is placed on the target, and sputtering occurs after being bombarded by argon ions. If the target material is simple, a simple film of the target substance will be formed on the substrate; if the reactive gas is consciously introduced into the sputtering chamber, it will chemically react with the sputtered target atoms and deposit on the substrate, A compound film of the target material can be formed. Usually, compound or alloy thin films are obtained by direct sputtering with compound or alloy targets. In sputtering, the sputtered atoms are sputtered after exchanging energy with high-energy ions with thousands of electron volts, and their energy is high, often 1 to 2 orders of magnitude higher than that of evaporated atoms. Adhesion of the film to the substrate is better than evaporation. If the substrate is properly biased during sputtering, the cleaning of the substrate can be taken into account, which is also beneficial to the step coverage of the generated film.

In addition, the sputtering method can be used to prepare high melting point and low vapor pressure material films that cannot be prepared by evaporation, which is convenient for the preparation of thin films of compounds or alloys. There are two main methods of sputtering: ion beam sputtering and plasma sputtering. In the ion beam sputtering device, a directional ion beam with a certain energy provided by the ion gun bombards the target to produce sputtering. The ion gun can also be used for cleaning the substrate and sputtering the target. To avoid charge buildup on insulating solid surfaces, energetically neutral beam sputtering can be used. A neutral beam is the result of energetic positive ions being neutralized by electrons before exiting the ion gun. Ion beam sputtering is widely used in surface analysis instruments to clean or strip samples. Due to the limited size of the beam spot, it is still difficult to quickly deposit thin films on large-area substrates.

the

Plasma sputtering is also called glow discharge sputtering. The positive ions required to produce sputtering come from the plasma in a glow discharge. The surface of the target must be at a high negative potential. After being accelerated by this electric field, the positive ions gain kinetic energy to bombard the target to produce sputtering, and at the same time, the bombardment of electrons to the substrate is inevitable.

The magnetron sputtering process of vacuum coating machine can also be divided into several types, mainly including two-stage sputtering, three-stage or four-stage sputtering, magnetron sputtering, target sputtering, radio frequency sputtering, bias sputtering, non- Symmetrical AC radio frequency sputtering, ion beam sputtering and reactive sputtering, etc., which sputtering method to choose depends on the workpiece to be plated, the material of the workpiece, and the coating layer.

What is the difference before and after the workpiece is plated by the vacuum coating machine?

2023-03-11

What is the difference before and after the workpiece is plated by the vacuum coating machine?

2023-03-11

Vacuum coating machines are widely used in various industries, including machinery, electronics, hardware, aerospace, medical, chemical and other fields.

Vacuum coating machine design should pay attention to details

2023-03-03

Vacuum coating machine design should pay attention to details

2023-03-03

In order to ensure that the vacuum coating machine has good sealing performance, it is necessary to cut off the cause of possible leaks at the source

How to check for leaks during installation and commissioning of vacuum coating machine

2023-03-03

How to check for leaks during installation and commissioning of vacuum coating machine

2023-03-03

The leak detection link of the vacuum coating machine is a step that needs to be carried out in all links from design, manufacture, commissioning, use, etc., and it is absolutely necessary.

Vacuum coating machine sputtering sputtering process introduction

2023-03-03

Vacuum coating machine sputtering sputtering process introduction

2023-03-03

The sputtering method can be used to prepare material films with high melting point and low vapor pressure that cannot be prepared by the evaporation process, which is convenient for the preparation of thin films of compounds or alloys. The vacuum coating machine sputtering sputtering process is mainly used for sputtering etching and film deposition. .

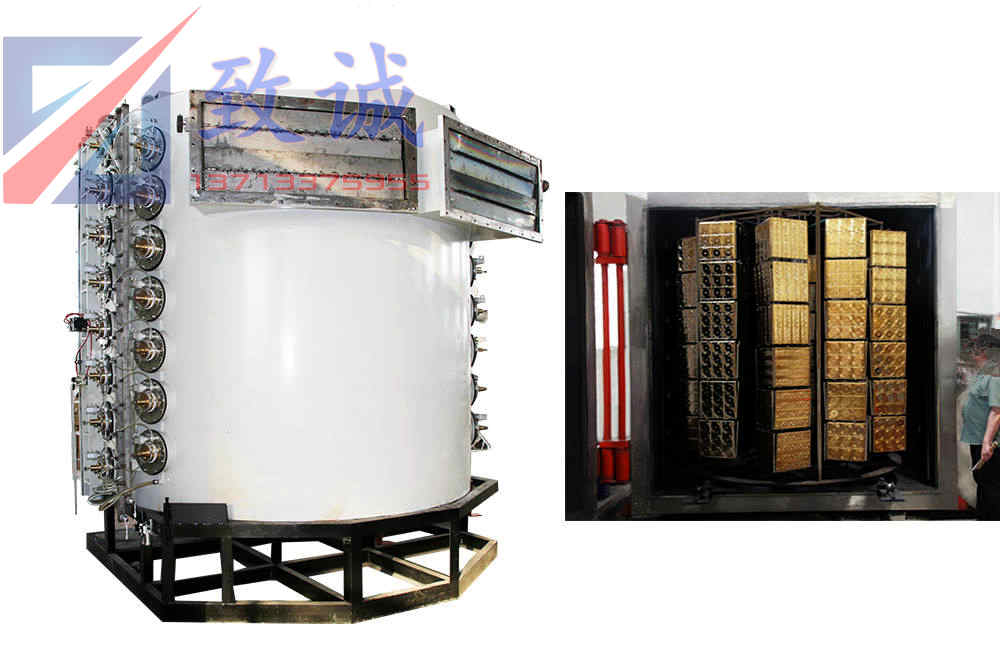

Magnetic control evaporation dual-purpose coating machine

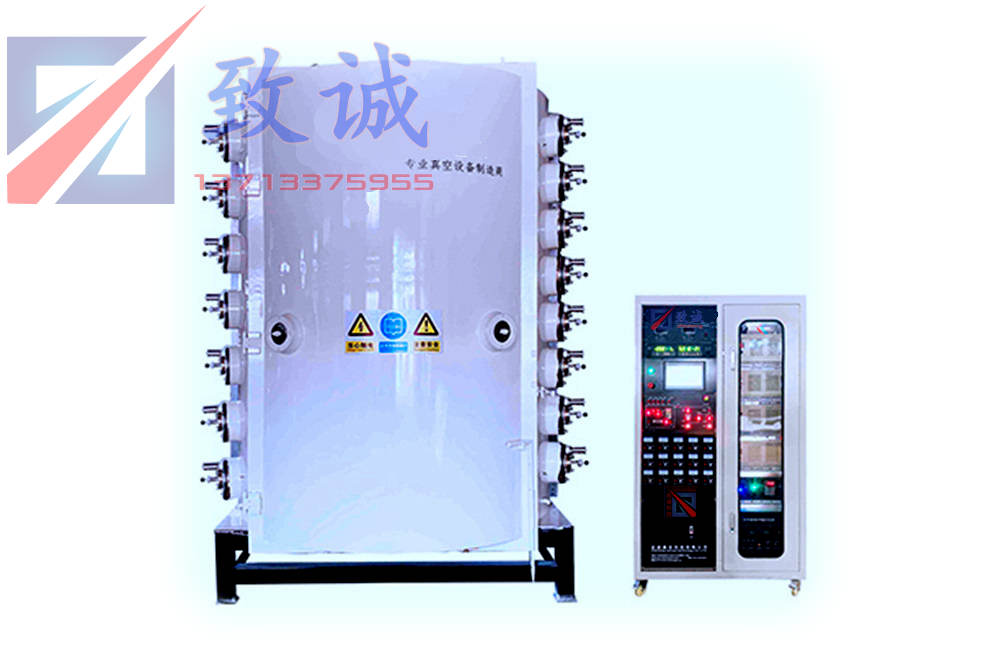

Intermediate frequency ion coating machine

Multi-arc ion coating machine for hardware

Ceramic Vacuum Coating Machine

Large stainless steel coating machine

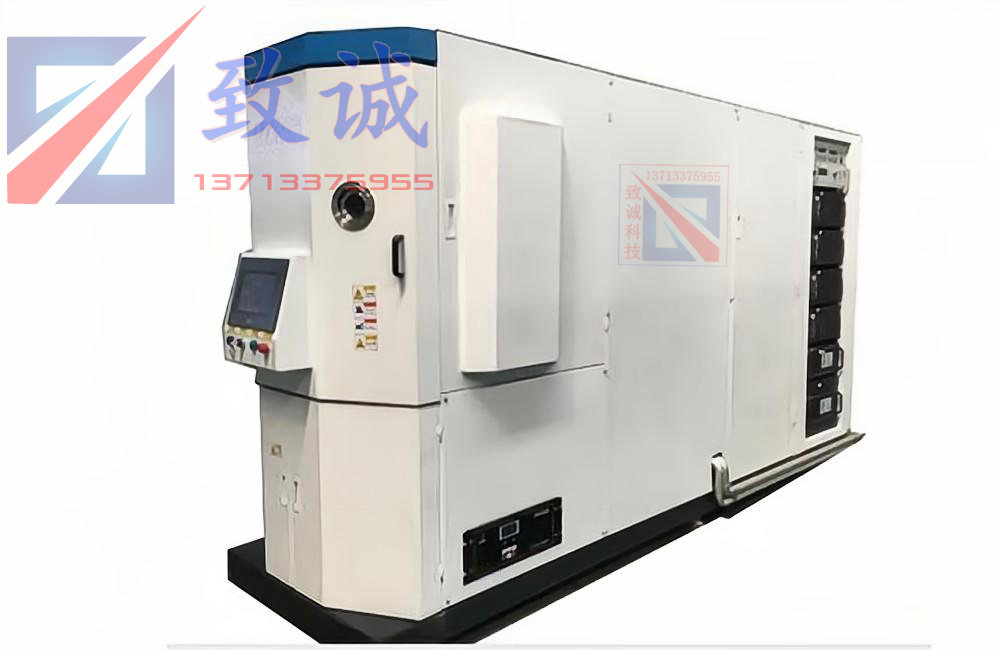

Glass special coating machine

Kitchenware Coating Equipment

Super hard film vacuum coating equipment

Dongguan City, Guangdong Province, China

+86 137-1337-5955

+86 13713375955 (Mr. Deng)

dgzhicheng@gmail.com

Copyright © 2022 Dongguan Zhicheng Technology Co., Ltd.