Server-Online

137-1337-5955

13713375955

Vacuum coating machines are widely used in various industries, including machinery, electronics, hardware, aerospace, medical, chemical and other fields, so what is the difference between PVD vacuum coating machines before and after coating, and where is it reflected?

Let's introduce it in detail:

Briefly talk about the difference before and after PVD coating:

1.

After the product is coated, a protective film will be formed on the surface of the product, which can effectively resist corrosion, be more wear-resistant, and improve product quality.

2.

Coating can change the appearance of the product. It can be electroplated with different colors and appearances according to different product customer groups to meet consumer needs, such as 18k gold vacuum coating for hardware.

3.

The thicker the electroplated film layer, the longer the color retention time.

4.

After electroplating, because of the extension of quality and service life, it can bring added value to the product, which is conducive to improving the economic benefits of the product.

For PVD vacuum coating, different products should choose the appropriate electroplating process, magnetron sputtering plating (mainly metal products), evaporation plating (mainly plastic products), optical ion plating (mainly glass products), and there are also a variety of colors to choose from. .

What is the difference before and after the workpiece is plated by the vacuum coating machine?

2023-03-11

What is the difference before and after the workpiece is plated by the vacuum coating machine?

2023-03-11

Vacuum coating machines are widely used in various industries, including machinery, electronics, hardware, aerospace, medical, chemical and other fields.

Vacuum coating machine design should pay attention to details

2023-03-03

Vacuum coating machine design should pay attention to details

2023-03-03

In order to ensure that the vacuum coating machine has good sealing performance, it is necessary to cut off the cause of possible leaks at the source

How to check for leaks during installation and commissioning of vacuum coating machine

2023-03-03

How to check for leaks during installation and commissioning of vacuum coating machine

2023-03-03

The leak detection link of the vacuum coating machine is a step that needs to be carried out in all links from design, manufacture, commissioning, use, etc., and it is absolutely necessary.

Vacuum coating machine sputtering sputtering process introduction

2023-03-03

Vacuum coating machine sputtering sputtering process introduction

2023-03-03

The sputtering method can be used to prepare material films with high melting point and low vapor pressure that cannot be prepared by the evaporation process, which is convenient for the preparation of thin films of compounds or alloys. The vacuum coating machine sputtering sputtering process is mainly used for sputtering etching and film deposition. .

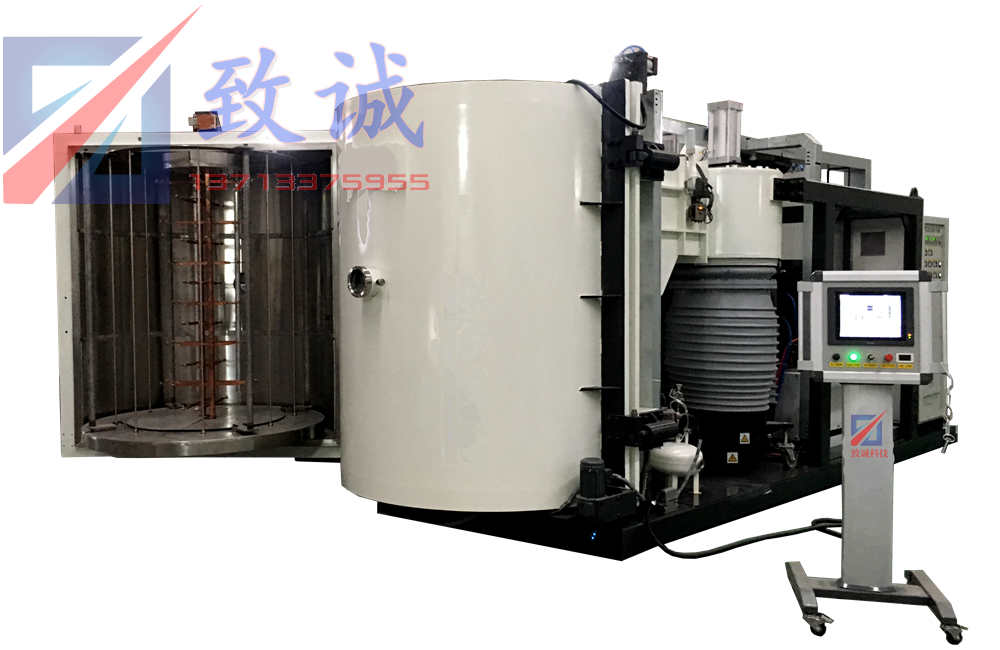

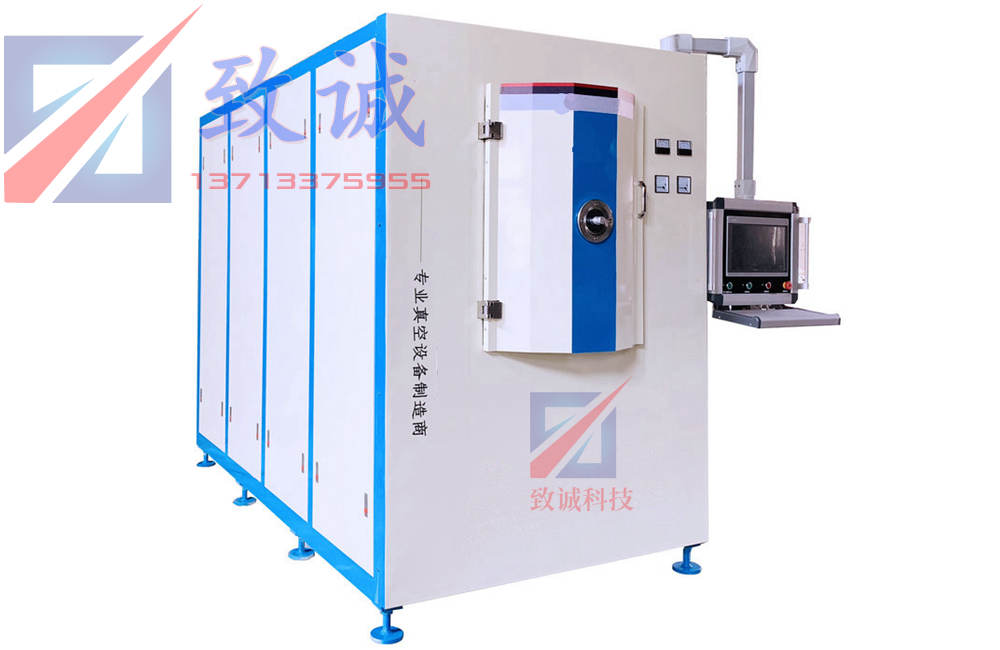

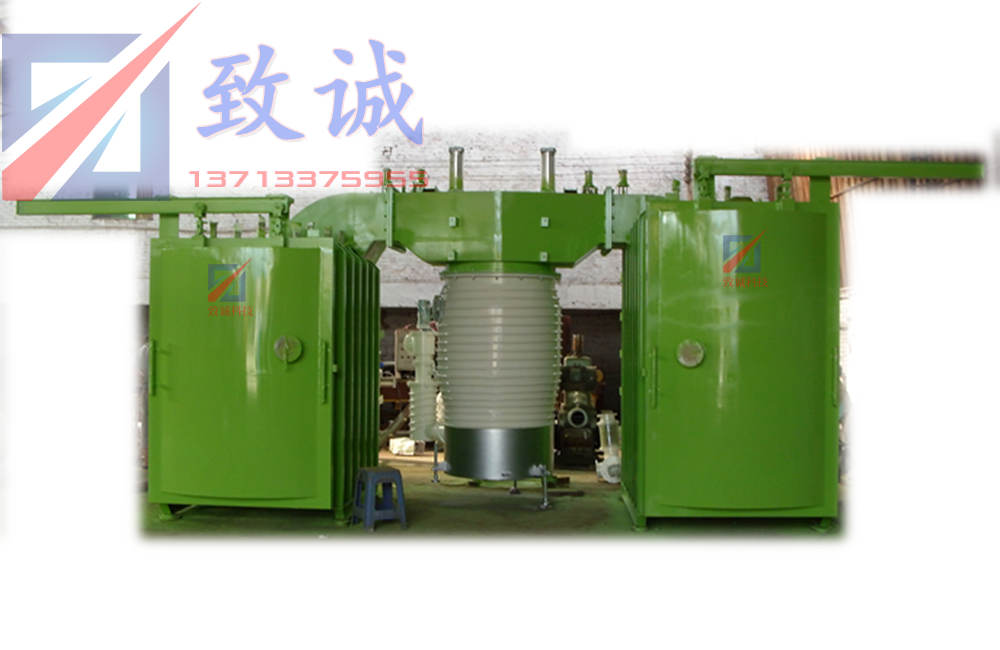

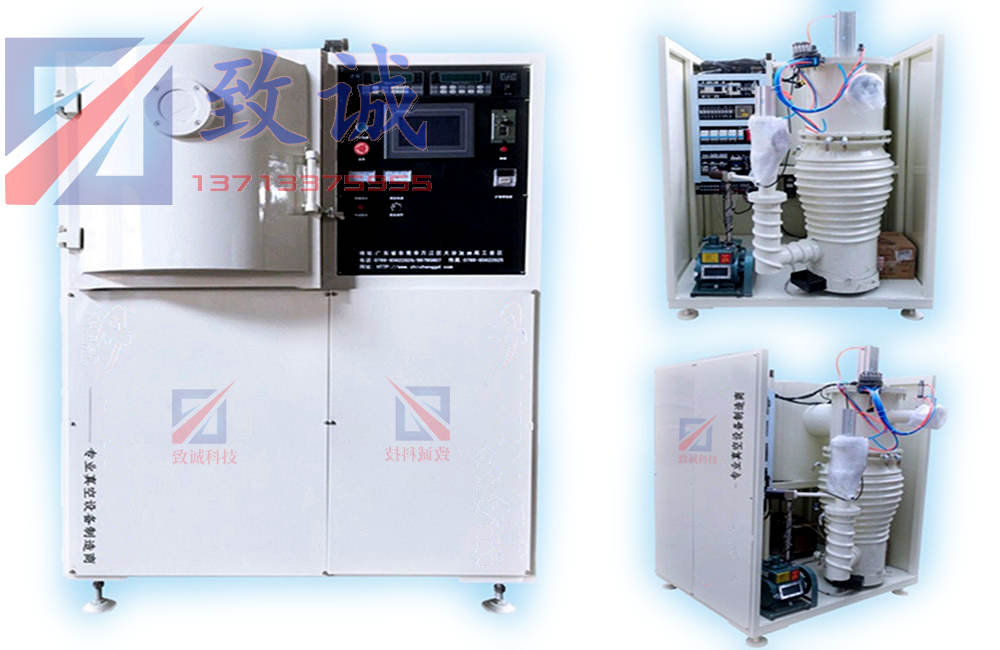

Vertical double-door-high vacuum evaporation coating machine

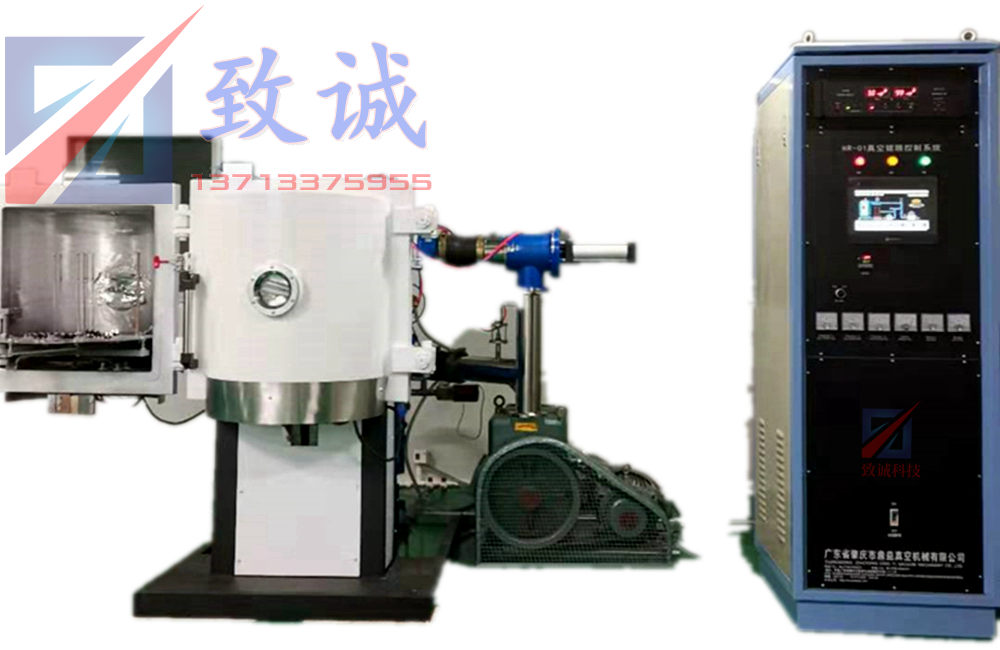

Horizontal evaporation coating machine

Vacuum coating machine for lamps

AF anti-fingerprint coating machine

PVD aluminum mirror coating machine

Vacuum internal plating equipment - evaporation coating machine - plastic/glass lampshade

Magnetic control evaporation dual-purpose coating machine

Laboratory coating equipment

Dongguan City, Guangdong Province, China

+86 137-1337-5955

+86 13713375955 (Mr. Deng)

dgzhicheng@gmail.com

Copyright © 2022 Dongguan Zhicheng Technology Co., Ltd.