Server-Online

137-1337-5955

13713375955

1,

Vacuum coating makes the plastic surface have a metallic texture; because compared with metal parts such as aluminum, copper, iron, and stainless steel, the manufacturing process of plastic parts has unique advantages such as large batches, low cost and easy processing. Plastic parts processed by surface vacuum coating In terms of the appearance of industrial products, metal parts have been or are being replaced more and more widely, which greatly reduces the manufacturing cost of industrial and consumer electronics products, and improves and consolidates the price advantage of products in the same industry competition.

2,

Endow plastic products with electrical conductivity; compared with pure plastic parts, plastic products processed by vacuum coating can endow products with good electrical conductivity according to the needs of the use occasions, such as the electromagnetic shielding performance (EMI) emphasized in the manufacturing process of most electronic consumer goods. It can be obtained by conducting conductive vacuum coating process on the inner wall of plastic parts. Under the same effect, compared with the original manufacturing process using copper foil or aluminum foil, the vacuum coating EMI process has an incomparable cost advantage.

3.

Non-conductive vacuum plating (NCVM) can be carried out; for the decorative parts of electronic consumer goods that need to transmit wireless signals to the outside during the work process, it is necessary for the plastic parts to have a metallic luster while ensuring that the metal plating layer on the plastic surface will not shield or To attenuate the radio signal of the device (such as Bluetooth signal, radio frequency signal, etc.), the non-conductive vacuum coating (NCVM) technology came into being. This vacuum coating technology not only ensures the metal texture of the plastic surface, but also does not affect the external appearance of the device. Signal transmission; Compared with the conductive coating of water electroplating that affects electronic signals, the non-conductive vacuum plating (NCVM) process provides a perfect choice for the majority of design and development engineers to have both fish and bear's paw.

4.

Single-layer electroplating can be carried out; generally speaking, the outer surface of the plastic product or the inner surface of the plastic product can be vacuum-plated separately, while the other surface can retain the original appearance and function of the plastic. For the water electroplating process of immersion operation, it is another hurdle that cannot be overcome.

5.

Vacuum electroplating processing technology has diversified colors. Due to the convenience of vacuum electroplating process, the formula and proportion can be adjusted on the basis of the three primary colors of red, yellow and blue to form ever-changing electroplating color effects (such as pink, red, green, etc.). However, water electroplating can only produce a few color effects such as light chrome, matte chrome, black chrome, and white chrome, which is not the same as the richness of vacuum electroplating.

6.

The material has a wide range of adaptability; water electroplating can usually only be electroplated on ABS plastic and a small amount of ABS+PC plastic material, which has certain limitations, and the vacuum electroplating process can be applied to a wide range of plastic materials, except for ABS, ABS+PC In addition to PC plastics, vacuum electroplating can also process metal coating effects on the surface of PC, PP, PMMA, PA, PS, PET and other common engineering plastics. With the development of technology and maturity, vacuum coating can even be performed on soft plastic surfaces. Processed, such as TPU, TPE, PVC soft rubber, silicone, rubber products, etc.

7.

Translucent vacuum electroplating is possible; in view of the increasingly trendy appearance design of modern consumer electronics products, the hidden display screens of the front-end electronic products now use translucent vacuum electroplating technology. There is a layer of transparent plastic window that has been processed by translucent vacuum plating on the outside. When the device is not turned on, its LED display panel is hidden and invisible. When the device is powered on, the LED luminous characters on the display panel can be seen through the plating The plastic window is seen by consumers or users, which greatly improves the sense of technology and fashion of the product.

8,

Environmentally friendly and non-toxic; vacuum plating technology is a process of physically attaching molten metal ions to the surface of plastic products to form a coating layer. The whole process does not need to add any chemicals or chemical agents. It is a pure natural non-toxic Environmentally friendly processing technology, with the increasing emphasis on green environmental protection in the world, water electroplating processing technology through chemical methods has gradually faded out of high-end consumer electronics, food-related products, toys and related industries.

9,

Increase the hardness of the plastic surface; the easy-to-form characteristics of plastic materials determine that the surface does not have good scratch resistance. After the UV vacuum plating is completed, a layer of photocurable UV coating is added on the surface of the coating layer, which greatly improves The hardness of the product surface is improved, and the scratch resistance, scratch resistance and wear resistance of the product are improved. The maximum hardness can reach 4H level, which is far beyond the scratch resistance and wear resistance level of the water electroplating process.

10.

Excellent environmental weather resistance; the vacuum electroplating process can endow the product with better performance in extreme use environments, such as high temperature and high humidity resistance, low temperature resistance, heat resistance, high salt content (salt spray resistance), UV aging resistance, and Cosmetics, sweat resistance, acid and alkali resistance and other properties; general oil injection process or water electroplating process cannot meet these performance requirements. I believe that behind the crazy growth of new IoT hardware and e-cigarettes, there will be more opportunities and challenges, which requires more cross-border exchanges and thinking of CMF personnel.

How to maintain the vacuum coating machine

2023-03-27

How to maintain the vacuum coating machine

2023-03-27

When the buyer purchases the vacuum coating machine, the manufacturer Shengchang equipment will generally be equipped with a machine maintenance manual. Both the buyer and the manufacturer attach great importance to the maintenance of the vacuum coating machine.

Why does the evaporation coating machine coat under vacuum conditions

2023-03-11

Why does the evaporation coating machine coat under vacuum conditions

2023-03-11

If the pressure is not low enough (or the vacuum degree is not high enough), good results cannot be obtained. For example, if aluminum is deposited on the order of 10 2 Torr, the obtained film is not only not bright, but even gray and black. And the mechanical strength is extremely poor.

What is the difference between PVD vacuum coating machine and CVD coating machine?

2023-03-11

What is the difference between PVD vacuum coating machine and CVD coating machine?

2023-03-11

Thin film deposition technology is mainly divided into three major processes: physical, chemical, and epitaxy. Physical vapor deposition is referred to as PVD vacuum coating machine. Chemical vapor deposition is referred to as CVD coating machine for short.

Vacuum conditions in the process of vacuum evaporation coating machine

2023-03-03

Vacuum conditions in the process of vacuum evaporation coating machine

2023-03-03

In the vacuum chamber, when the particle concentration in the gas phase and the pressure of the residual gas are low enough, these particles can keep flying in a straight line from the evaporation source to the substrate, otherwise, they will collide and change the direction of motion.

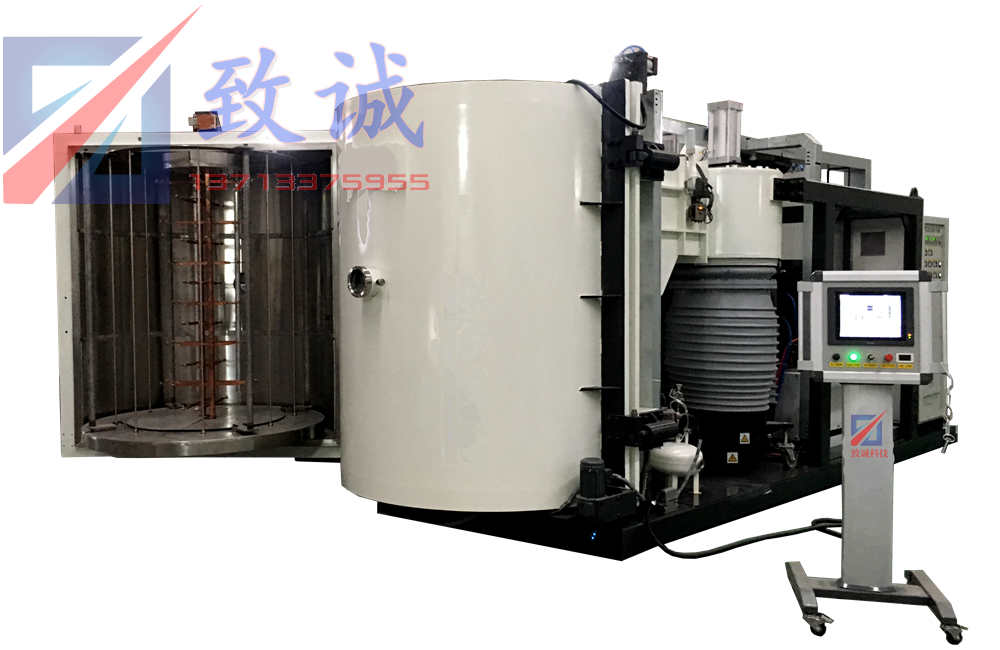

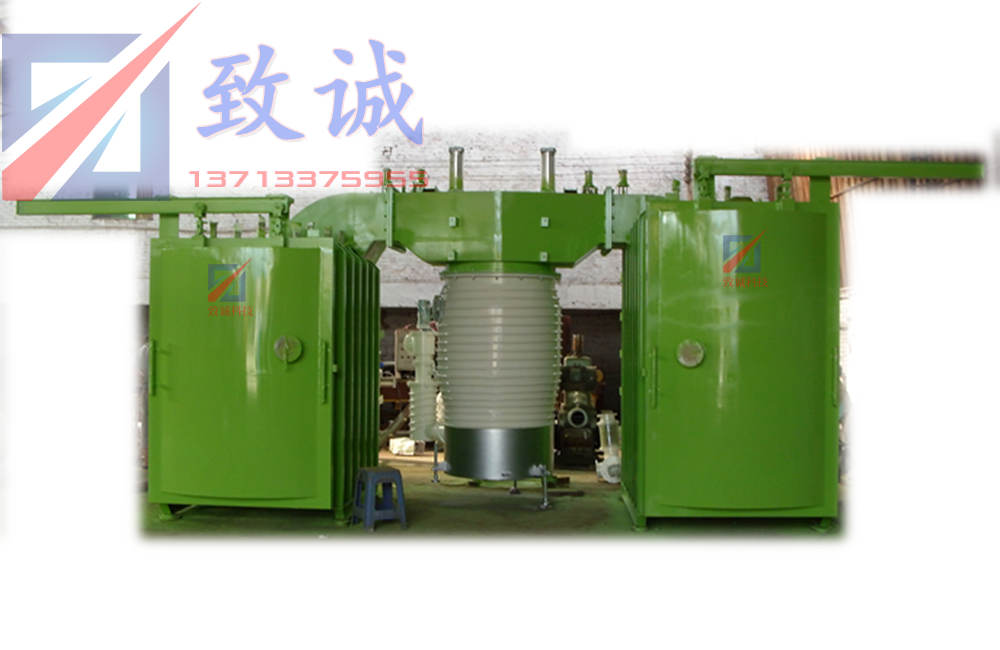

Vertical double-door-high vacuum evaporation coating machine

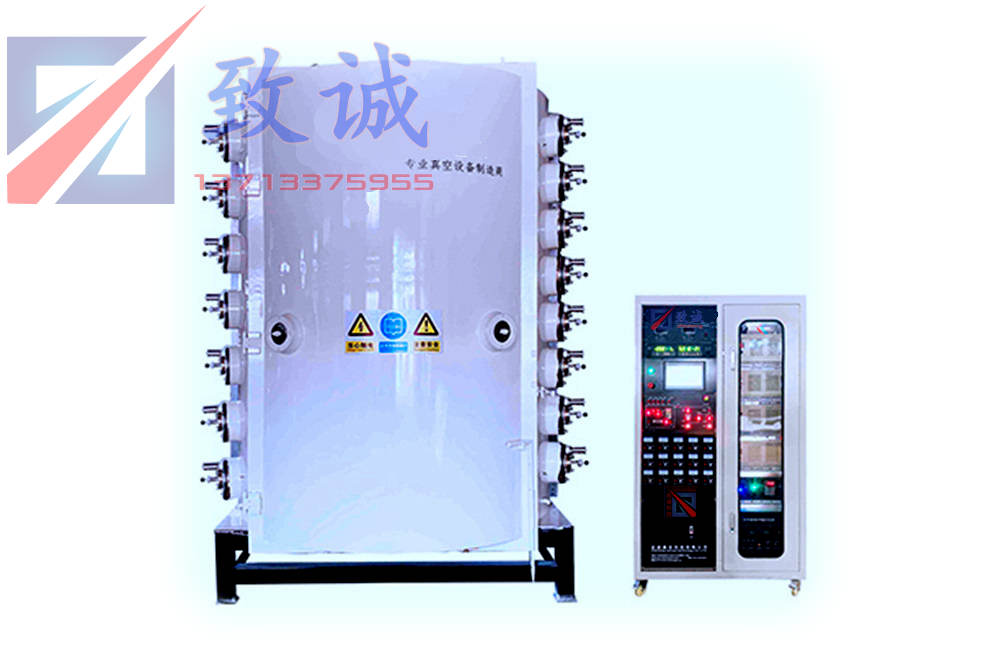

Vacuum coating machine for lamps

AF anti-fingerprint coating machine

PVD aluminum mirror coating machine

Magnetic control evaporation dual-purpose coating machine

Multi-arc ion coating machine for hardware

Intermediate frequency ion coating machine

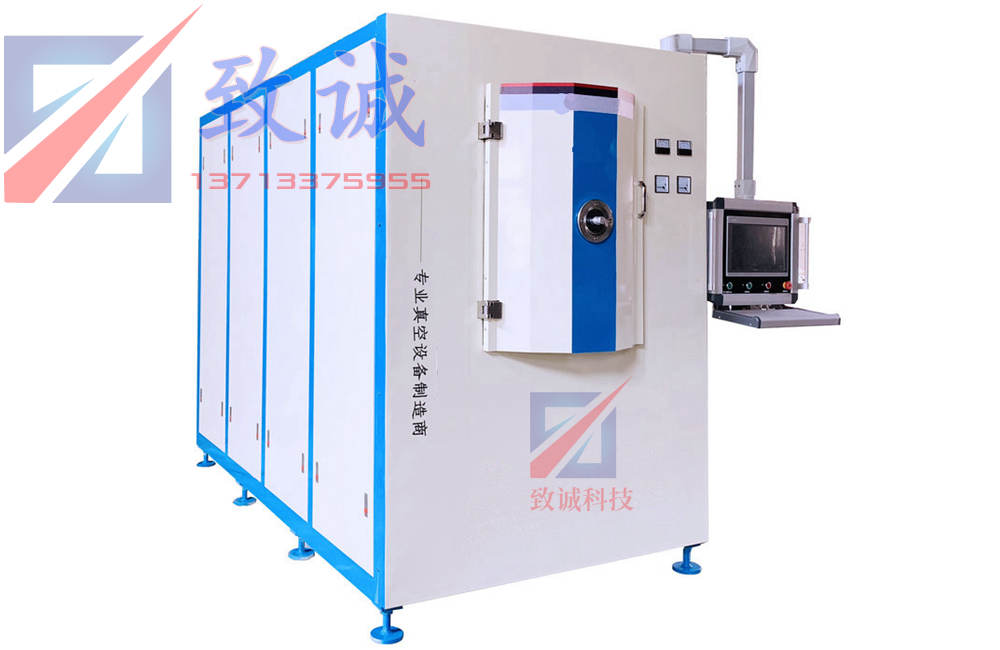

Glass special coating machine

Dongguan City, Guangdong Province, China

+86 137-1337-5955

+86 13713375955 (Mr. Deng)

dgzhicheng@gmail.com

Copyright © 2022 Dongguan Zhicheng Technology Co., Ltd.