Server-Online

137-1337-5955

13713375955

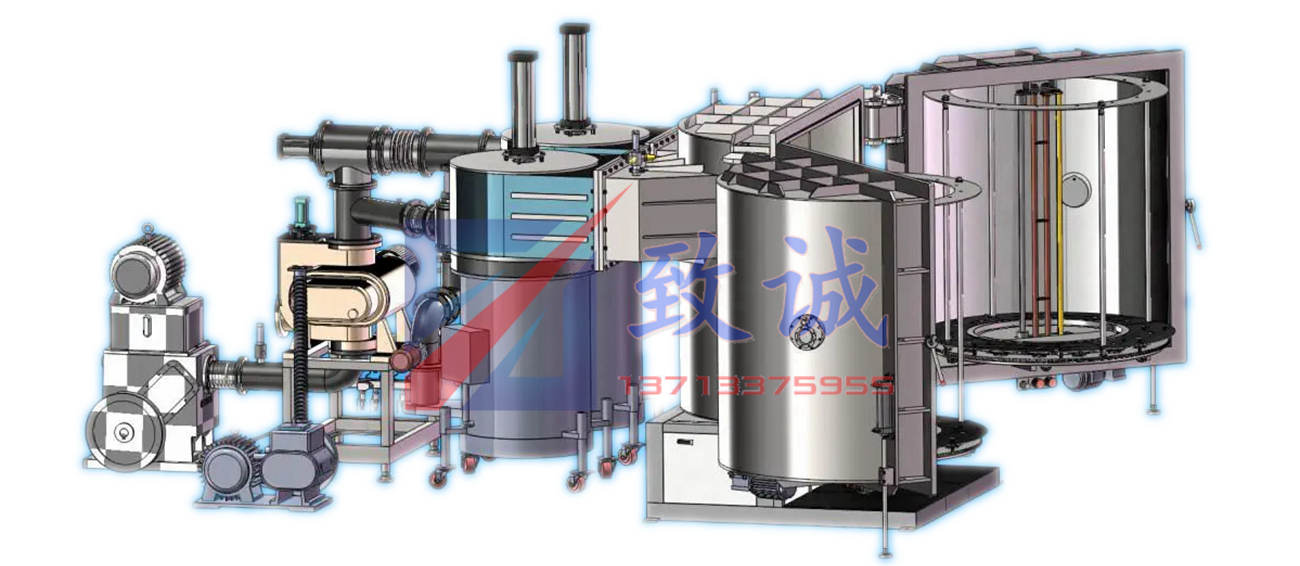

Magnetron sputtering coating machine

PVD magnetron coating machine

Aluminum film PVD electroplating equipment

Silver film PVD plating equipment

Chromium film vacuum plating equipment

Low temperature vacuum plating equipment

Low temperature vacuum coating equipment

High Vacuum Evaporation Coating Machine

PVD vacuum coating equipment

High vacuum evaporation coating equipment

Magnetic control evaporation dual-purpose coating machine

Magnetic control evaporation dual-purpose coating machine

Magnetron Evaporation Vacuum Coating Machine

Plastic metallization electroplating equipment

Evaporation/magnetic control dual-purpose coating equipment:

Magnetic control/evaporation dual-purpose coating equipment:

This equipment uses magnetron sputtering negative glow discharge to ionize and deposit atoms (target material) on the substrate (Physical Vapor Deposition PVD) and uses resistance heating method in vacuum to melt the metal wire or vaporize the metal molecules. , metallize the plastic surface such as mobile phone shell, and use specific film coating to realize the function of non-conduction and electromagnetic shielding of the product, so as to meet the current industry standard of advanced electronic product manufacturing for mobile phones;

Magnetic control/evaporation dual-purpose coating equipment:

Concentrated plasma treatment, advanced cathode magnetron sputtering, resistance evaporation coating device, large loading capacity turret and automatic control technology, reliable work, good repeatability, high deposition rate, good adhesion, the film layer Fine quality, etc., the plated film is compact, high hardness, low friction coefficient, can keep the original workpiece surface smooth, has good toughness, and is not easy to break and fall off. The equipment realizes the fully automatic control of the coating process. The surface of the substrate is coated by vacuum coating method, which has the characteristics of low production cost, high product qualification rate, green environmental protection, etc. It is mainly suitable for computers, mobile phones, high-level industrial (household) electronic appliances, aviation and other fields, and can be plated Composite metal film, alloy film, transparent (translucent) film, non-conductive film, electromagnetic shielding film and special film, etc.

Equipment parameters:

| model |

Studio size diameter X length (mm) |

Maximum size and diameter of workpieces that can be plated(mm) |

extreme pressure(Pa) |

No-load pumping time (minutes) |

Total installed power (KW) |

Evaporation power (KW) |

Vacuum unit configuration |

|

DY-1200 |

Φ1200X1400 |

Φ330X1200X6 |

≤3X10-3 |

≤6 |

53 |

20 |

KT-600;ZJ-300;2X-8;2X-70 |

|

DY-1400 |

Φ1400X2000 |

Φ400X1700X6 |

≤3X10-3 |

≤6 |

65 |

20 |

KT-800;ZJ-600;2X-15;H-150 |

|

DY-1600 |

Φ1600X2000 |

Φ470X1700X6 |

≤3X10-3 |

≤6 |

75 |

30 |

KT-1000;ZJ-600;2X-30;H-150 |

|

DY-1700 |

Φ1700X2000 |

Φ500X1700X6 |

≤3X10-3 |

≤6 |

77 |

30 |

KT-1000;ZJ-1200;2X-30;H-150 |

|

DY-1800 |

Φ1800X2000 |

Φ530X1700X6 |

≤3X10-3 |

≤6 |

96.5 |

30 |

KT-1000;ZJ-1200;2X-30;H-150 |

|

DY-2000 |

Φ2000X2000 |

Φ590X1700X6 |

≤3X10-3 |

≤6 |

96.5 |

30 |

KT-1000,ZJ-1200;2X-30;H-150X2 |

|

DY-1000 |

Φ1000X2000 |

Φ310X1700X6 |

≤3X10-3 |

≤6 |

53 |

30 |

KT-800;ZJ--600.2X15;H-150 |

|

DY-1500 |

Φ1500X2000 |

Φ480X1700X6 |

≤3X10-3 |

≤6 |

65 |

30 |

KT-800;ZJ-600;2X-15;H-150 |

|

DY-1600 |

Φ1600X2000 |

Φ520X1700X6 |

≤3X10-3 |

≤6 |

75 |

30 |

KT-800;ZJ-1200;2X-30;H-150 |

|

DY-1800 |

Φ1800X2000 |

Φ580X1700X6 |

≤3X10-3 |

≤6 |

96.5 |

30 |

KT-1000;ZJ-1200;2X-300;H-150 |

|

DY-2000 |

Φ2000X2000 |

Φ600X1700X6 |

≤3X10-3 |

≤6 |

96.5 |

30 |

KT-800X2;ZJ-1200;2X-300;H-150X2 |

Sample example:

Zhicheng Technology

Vacuum coating machines of various specifications and models can be designed according to user requirements.

The vacuum unit and electronic control system can also be designed and configured according to user requirements.

Zhicheng Technology's world-leading coating application solutions: provide equipment, materials, processing, technology, project support and other system services

Zhicheng vacuum coating equipment includes: evaporation coating machine, magnetron sputtering coating machine, magnetron evaporation dual-purpose coating machine, multi-arc ion coating machine, intermediate frequency ion coating machine, AF coating machine, super hard coating coating machine, winding Type coating machine, PVD coating line, coating project supporting assembly.

PVD process technology uses vacuum conditions to deposit various metal and non-metal films on the surface of plastic parts by means of distillation or sputtering.

Zhicheng Technology matches the best coating process scheme according to the characteristics of the product.

The advantages and characteristics of Zhicheng vacuum coating machine ancestor equipment in the industry are: professionalism, integrity and reliability.

Plastic Metallization - High Vacuum Evaporation Coating

Symphony/Colorful Plating-Vacuum Coating Equipment-Evaporation Coating Machine

Технология гальванического покрытия ступиц колес автомобилей и мотоциклов_Оборудование для вакуумных покрытий_Процесс магнетронного напыления

Vacuum evaporation coating machine_plastic metallization UV electroplating processing technology

Jewelry AFAR anti-fingerprint_medium frequency evaporation vacuum coating machine equipment

Technical Introduction of Resistance Evaporation Vacuum Coating Machine

Silicone oil protective coating equipment for car lamps - lampshade/reflector cup vacuum coating

Dongguan City, Guangdong Province, China

+86 137-1337-5955

+86 13713375955 (Mr. Deng)

dgzhicheng@gmail.com

Copyright © 2022 Dongguan Zhicheng Technology Co., Ltd.