Server-Online

137-1337-5955

13713375955

Colored glass coating automatic line

Colored glass coating production line

Glass magnetron coating production line

Glass coating automatic production line

Magnetron sputtering automatic coating line

Magnetron sputtering coating automatic line

Magnetron sputtering coating production line

Stained glass vacuum coating machine

Stained glass vacuum coating equipment

Continuous magnetron sputtering coating production line

Colored glass magnetron sputtering coating production line

Colored glass magnetron sputtering coating automatic line

Glass magnetron sputtering coating automatic production line

Colored glass magnetron sputtering coating automatic production line

Colored Glass Magnetron Sputtering Coating Line - Continuous Magnetron Sputtering Coating Line

Colored glass continuous magnetron sputtering coating production line - Magnetron sputtering coating production line

Colored Glass Magnetron Sputtering Coating Automatic Production Line - Continuous Magnetron Sputtering Coating Automatic Production Line

Glass Magnetron Sputtering Coating Automatic Production Line - Continuous Magnetron Sputtering Vacuum Coating Equipment

Glass vacuum coating

Glass vacuum coating should be the most widely used glass product in curtain wall glass color (such as various low-e coated glass such as blue gray and silver gray). Its coloring principle is to apply a colored metal coating on the inside of the outer glass of the curtain wall.

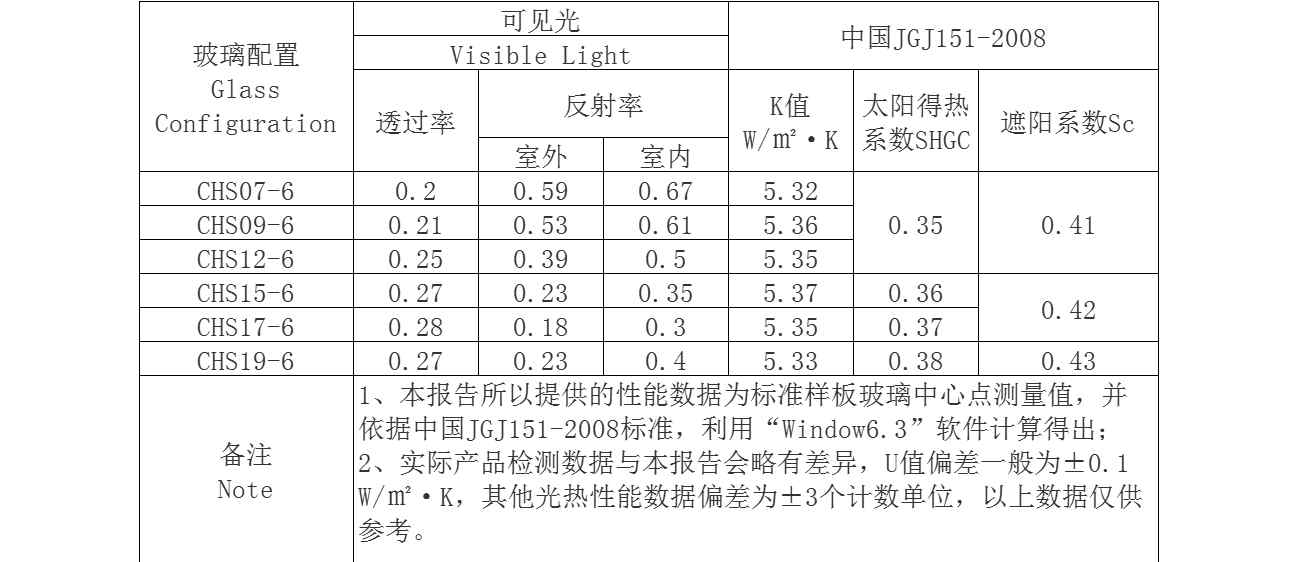

Coated glass has higher transmittance for visible light and higher reflectivity for infrared rays. Ordinary colored glass has a visible light reflectance of 20%-35%, and a shading coefficient of about 80%, while the visible light reflectance of coated colored glass products is usually 22%-80%, and the shading coefficient is about 50%. The higher the reflectivity, the brighter the glass; the lower the shading coefficient, the less sunlight enters the room, the less heat can be generated, and the more energy-saving!

Advantages of glass vacuum coating film:

1. The reflectivity is as high as 70%, which also means that the glass is very reflective and looks brighter!

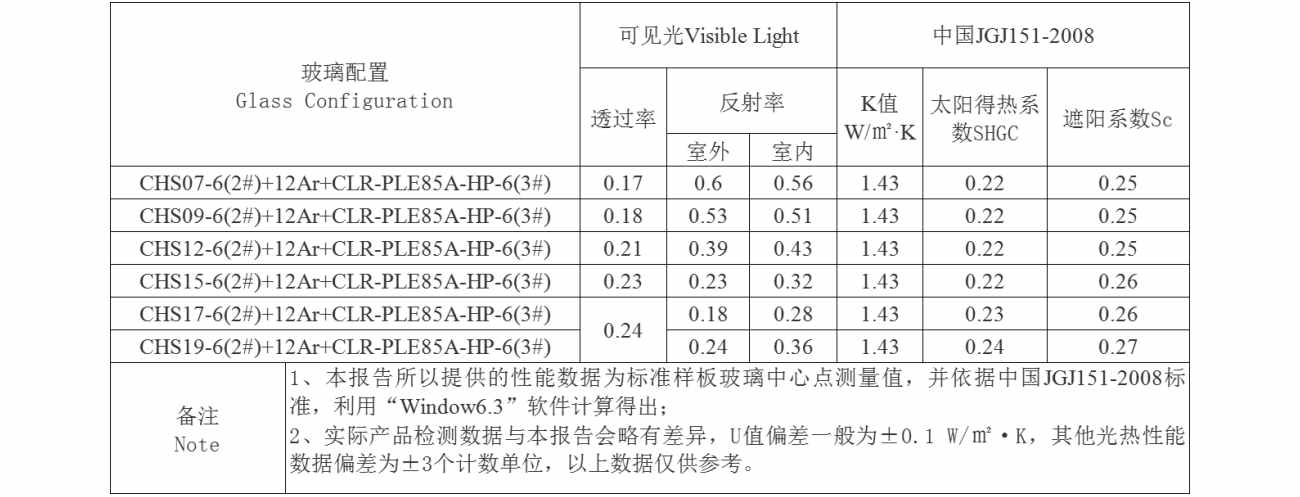

Parameters of 6mm float substrate iridescent coated glass:

2. Rainbow coated glass is a toughened glass product, which can not only be used as a single piece, but also can be further compounded into composite products such as interlayer, hollow, and bent steel.

3. Compared with coloring methods such as color PVB glue, color digital printing, etc., it greatly reduces the cost of use.

4. The entire series of products are rich in color, which is obviously different from the inherent color of colored glaze and the transparent color of film in terms of color texture, providing more diverse solutions for architectural design.

5. When used with high-performance Low-E glass PLE85A-HP, the shading coefficient is about 0.25, which can effectively limit the outdoor background heat radiation from entering the room in summer, and achieve an energy-saving effect comparable to double-silver Low-E!

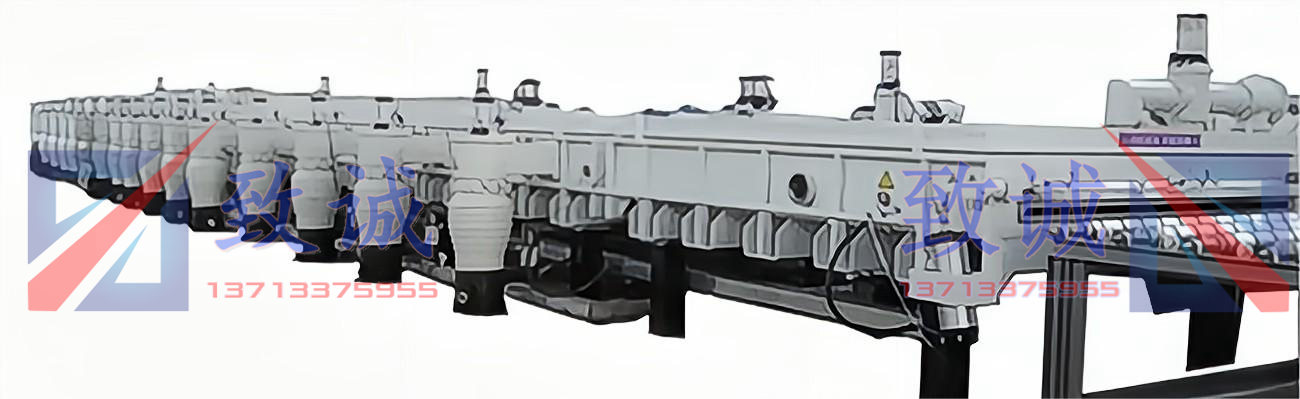

The color glass coating equipment developed by Dingyi Technology adopts the principle of magnetron sputtering, which can be coated on transparent colorless flat glass into 24K gold mirror, 18K gold mirror, khaki mirror, red gold mirror, purple mirror, purple mirror, violet mirror Color mirrors, blue mirrors, gray mirrors, brown mirrors, pink mirrors, pink mirrors, auspicious yellow mirrors and other color mirrors.

Features of colored glass magnetron sputtering coating production line equipment:

1. The size of glass that can be plated can reach: 2440X3660 mm

2. Multi-vacuum chamber, multi-sputtering chamber structure, available for users to choose

3. The horizontal magnetic control production line has single-end and double-end forms, glass double cleaning, plating, testing, painting, drying, cooling, etc. are completed at one time

4. The production line is controlled by PLC and equipped with a color display to show the glass process

coating effect

Zhicheng Technology

Vacuum coating machines of various specifications and models can be designed according to user requirements.

The vacuum unit and electronic control system can also be designed and configured according to user requirements.

Zhicheng Technology's world-leading coating application solutions: provide equipment, materials, processing, technology, project support and other system services

Zhicheng vacuum coating equipment includes: evaporation coating machine, magnetron sputtering coating machine, magnetron evaporation dual-purpose coating machine, multi-arc ion coating machine, intermediate frequency ion coating machine, AF coating machine, super hard coating coating machine, winding Type coating machine, PVD coating line, coating project supporting assembly.

PVD process technology uses vacuum conditions to deposit various metal and non-metal films on the surface of plastic parts by means of distillation or sputtering.

Zhicheng Technology matches the best coating process scheme according to the characteristics of the product.

The advantages and characteristics of Zhicheng vacuum coating machine ancestor equipment in the industry are: professionalism, integrity and reliability.

Dongguan City, Guangdong Province, China

+86 137-1337-5955

+86 13713375955 (Mr. Deng)

dgzhicheng@gmail.com

Copyright © 2022 Dongguan Zhicheng Technology Co., Ltd.