Server-Online

137-1337-5955

13713375955

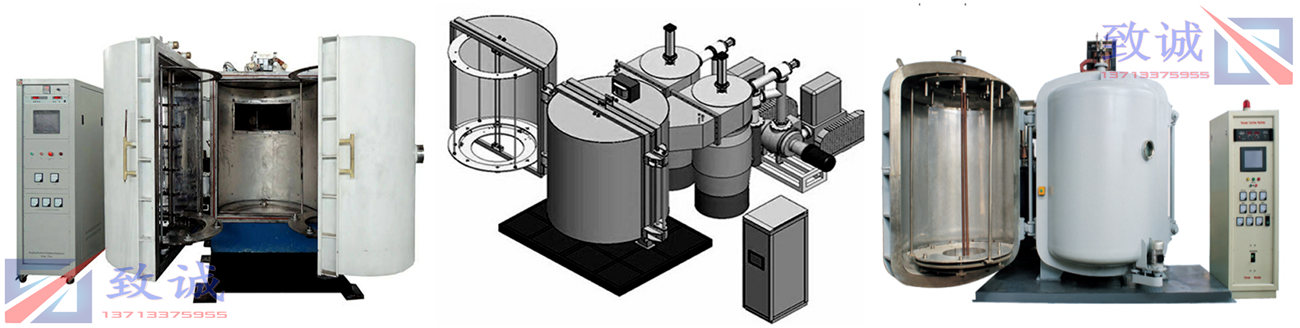

Evaporation coating machine

Evaporation coating equipment

Vacuum plating equipment

Low temperature vacuum coating machine

Normal temperature vacuum coating machine

Plastic colorful coating machine

Plastic colorful coating machine

Plastic Symphony Coating Machine

Plastic Symphony Coating Machine

High Vacuum Evaporation Coating Machine

Plastic Metallization Coating Machine

Plastic Professional Vacuum Coating Machine

Plastic Professional Vacuum Coating Machine

Vertical Double Door: High Vacuum Evaporation Coating Machine

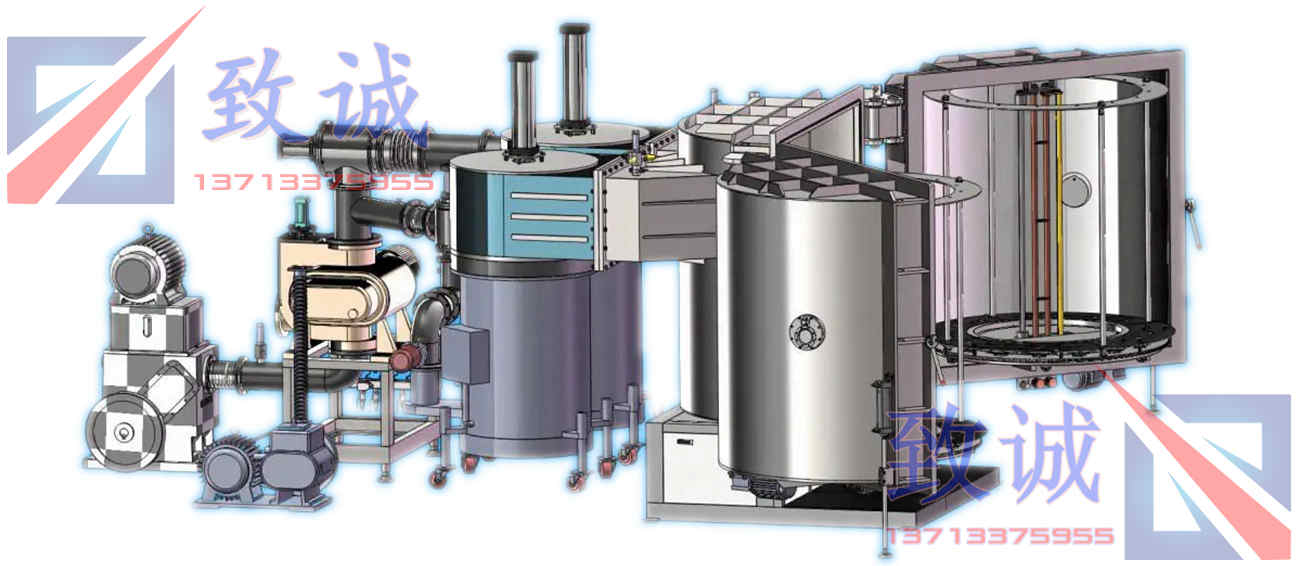

The principle of evaporative vacuum coating equipment is to melt and vaporize the metal wires (aluminum wire, copper wire, chromium wire...) on the resistance wire by using the resistance heating method in the vacuum state in the vacuum chamber. On the chip, a smooth and high-reflectivity film layer is obtained to achieve the purpose of decorating and beautifying the surface of the article.

Zhicheng Vacuum Evaporation Coating Machine: Aluminum Coating Machine, Mirror Coating Machine, Color Coating Machine

It has the advantages of reasonable structure, high pumping speed, short working cycle, high production efficiency, convenient operation, low energy consumption, stable work, uniform film layer and good film forming quality.

The equipment is mainly widely used in automobiles, audio, various small household appliances, computers, clocks, mobile phones, reflectors, cosmetics, toys and other industries.

Machinable materials include: ABS, PS, PP, PC, PVC, TPU, nylon, glass, ceramics, metal, etc.

The surface state of the substrate that can be plated: electroplating bright surface, semi-lens surface, matte surface (semi-dumb, full-dumb), process electroplating wrinkles, wire drawing, raindrops, etc.;

Plating colors are: gold, silver, red, blue, green, purple, black, colorful and other colors.

Zhicheng PVD equipment-vacuum evaporation coating machine model and technical parameters

| model |

Studio size diameter X length (mm) |

Maximum size and diameter of workpieces that can be plated(mm) |

extreme pressure(Pa) |

No-load pumping time (minutes) |

Total installed power (KW) |

Evaporation power (KW) |

Vacuum unit configuration |

|

DY-1200 |

Φ1200X1400 |

Φ330X1200X6 |

≤3X10-3 |

≤6 |

53 |

20 |

KT-600;ZJ-300;2X-8;2X-70 |

|

DY-1400 |

Φ1400X2000 |

Φ400X1700X6 |

≤3X10-3 |

≤6 |

65 |

20 |

KT-800;ZJ-600;2X-15;H-150 |

|

DY-1600 |

Φ1600X2000 |

Φ470X1700X6 |

≤3X10-3 |

≤6 |

75 |

30 |

KT-1000;ZJ-600;2X-30;H-150 |

|

DY-1700 |

Φ1700X2000 |

Φ500X1700X6 |

≤3X10-3 |

≤6 |

77 |

30 |

KT-1000;ZJ-1200;2X-30;H-150 |

|

DY-1800 |

Φ1800X2000 |

Φ530X1700X6 |

≤3X10-3 |

≤6 |

96.5 |

30 |

KT-1000;ZJ-1200;2X-30;H-150 |

|

DY-2000 |

Φ2000X2000 |

Φ590X1700X6 |

≤3X10-3 |

≤6 |

96.5 |

30 |

KT-1000,ZJ-1200;2X-30;H-150X2 |

|

DY-1000 |

Φ1000X2000 |

Φ310X1700X6 |

≤3X10-3 |

≤6 |

53 |

30 |

KT-800;ZJ--600.2X15;H-150 |

|

DY-1500 |

Φ1500X2000 |

Φ480X1700X6 |

≤3X10-3 |

≤6 |

65 |

30 |

KT-800;ZJ-600;2X-15;H-150 |

|

DY-1600 |

Φ1600X2000 |

Φ520X1700X6 |

≤3X10-3 |

≤6 |

75 |

30 |

KT-800;ZJ-1200;2X-30;H-150 |

|

DY-1800 |

Φ1800X2000 |

Φ580X1700X6 |

≤3X10-3 |

≤6 |

96.5 |

30 |

KT-1000;ZJ-1200;2X-300;H-150 |

|

DY-2000 |

Φ2000X2000 |

Φ600X1700X6 |

≤3X10-3 |

≤6 |

96.5 |

30 |

KT-800X2;ZJ-1200;2X-300;H-150X2 |

Sample of PVD evaporation coating:

Zhicheng Technology

Vacuum coating machines of various specifications and models can be designed according to user requirements.

The vacuum unit and electronic control system can also be designed and configured according to user requirements.

Zhicheng Technology's world-leading coating application solutions: provide equipment, materials, processing, technology, project support and other system services

Zhicheng vacuum coating equipment includes: evaporation coating machine, magnetron sputtering coating machine, magnetron evaporation dual-purpose coating machine, multi-arc ion coating machine, intermediate frequency ion coating machine, AF coating machine, super hard coating coating machine, winding Type coating machine, PVD coating line, coating project supporting assembly.

PVD process technology uses vacuum conditions to deposit various metal and non-metal films on the surface of plastic parts by means of distillation or sputtering.

Zhicheng Technology matches the best coating process scheme according to the characteristics of the product.

The advantages and characteristics of Zhicheng vacuum coating machine ancestor equipment in the industry are: professionalism, integrity and reliability.

Plastic Metallization - High Vacuum Evaporation Coating

Common sense of vacuum coating VS silver mirror spraying

Evaporation Coating Machine - Handicraft Electroplating

Symphony/Colorful Plating-Vacuum Coating Equipment-Evaporation Coating Machine

UV electroplating processing line - resistance evaporation vacuum coating machine

Vacuum evaporation coating machine_plastic metallization UV electroplating processing technology

Cosmetic Shell Electroplating_Evaporation Coating Machine_PVD Vacuum Coating Equipment

Evaporation magnetron dual-purpose vacuum coating machine

Technical Introduction of Resistance Evaporation Vacuum Coating Machine

Silicone oil protective coating equipment for car lamps - lampshade/reflector cup vacuum coating

Dongguan City, Guangdong Province, China

+86 137-1337-5955

+86 13713375955 (Mr. Deng)

dgzhicheng@gmail.com

Copyright © 2022 Dongguan Zhicheng Technology Co., Ltd.