PVD technology

Physical vapor deposition (PVD)

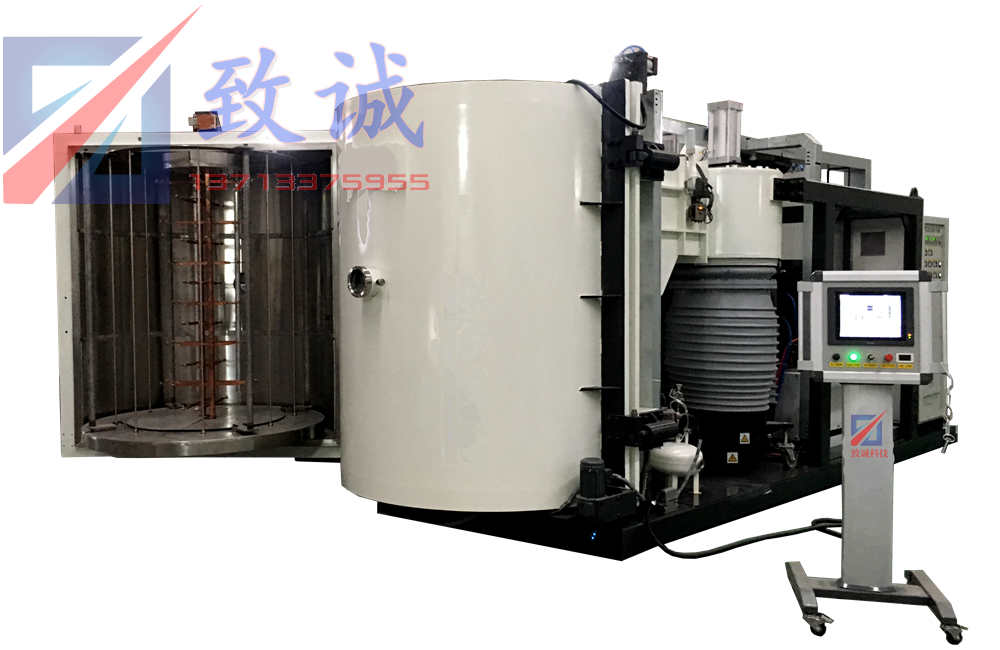

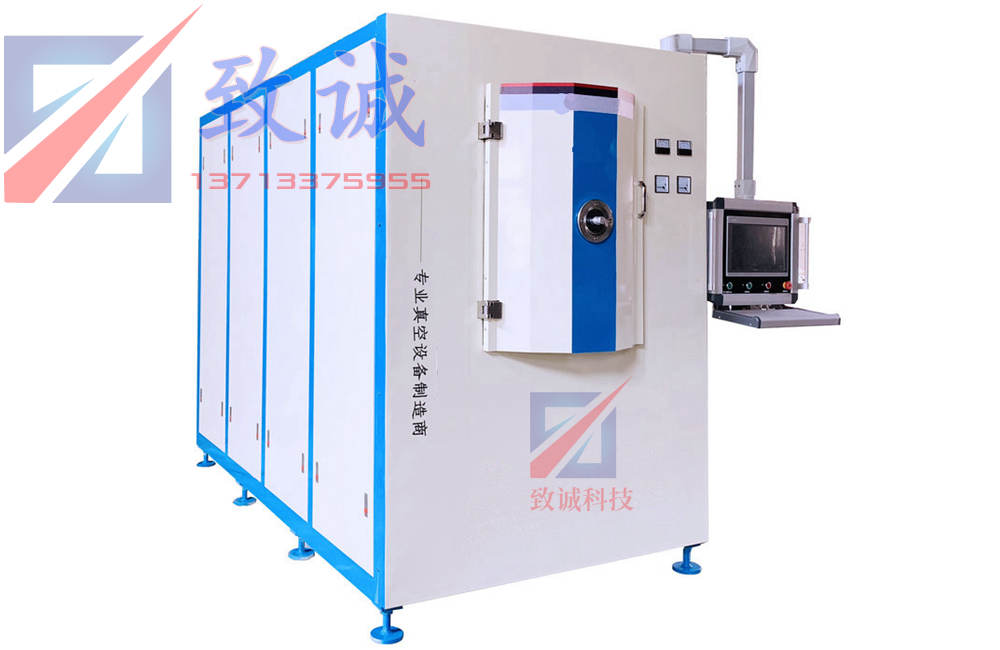

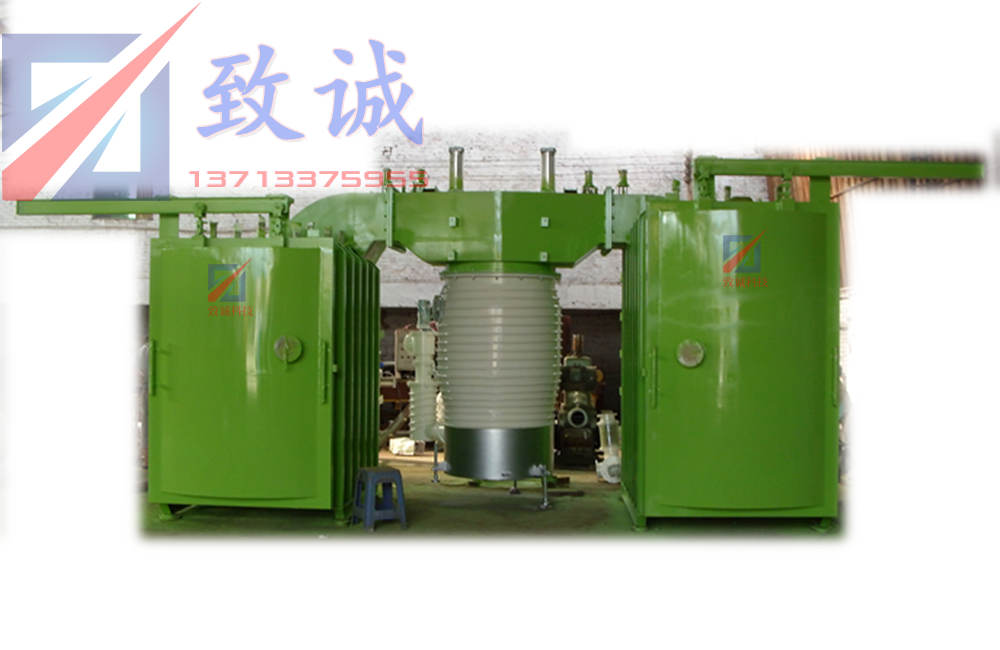

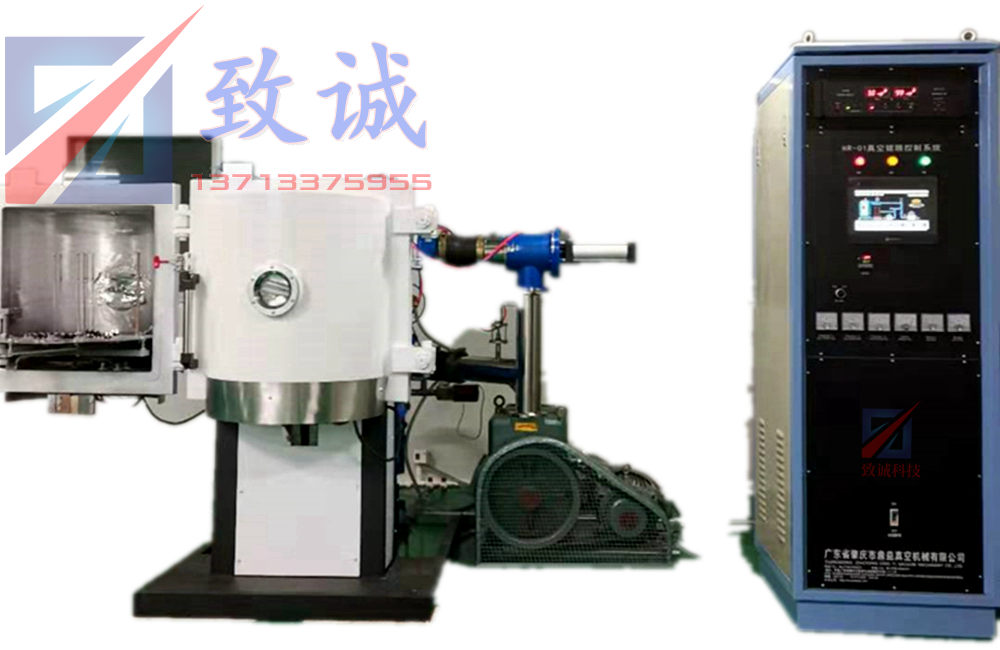

PVD is the abbreviation of physical vapor deposition. PVD is the technology of material evaporation deposition under vacuum. Vacuum chamber is a necessary condition to avoid the reaction of evaporated material and air. PVD coating is used to prepare new products with additional value and characteristics, such as gorgeous color, wear resistance and friction reduction. The physical vapor deposition (PVD) process is used to form a coating by condensing most metal materials and combining with gases, such as nitrogen. The matrix material is converted from solid state to gas state and is ionized by thermal energy as received in the arc process, or by kinetic energy as in the sputtering process. PVD technology is environmentally friendly and pollution-free. Zhicheng Vacuum Technology focuses on developing PVD coating.

Physical Vapor Deposition (PVD) covers special processes in the field of thin film technology. It refers to the coating process of depositing thin films on the substrate surface by physical means under vacuum.

As the most economical deposition method, sputtering process is regarded as the standard coating technology in many processes, and is widely used in many industrial fields. One of the main reasons why sputtering technology is so popular is that it can deposit a variety of materials on a wide variety of substrates.

Sputtering technology is widely used in many fields, such as surface treatment in semiconductor industry, production of polarizing filters in optical industry, or large-area surface coating in architectural glass industry.

We not only provide coating equipment to customers, but also develop and produce sputtering target materials by ourselves. Our professional experience has been continuously improved through more than 15 years of practical experience.

In all PVD processes, the materials used to grow films are initially solid and are often placed somewhere in the process chamber, such as sputtering target. In order to vaporize the material and then polymerize and deposit it on the surface of the substrate in the form of a film, various methods will be applied in the process (for example, using short-time, high-energy radio frequency pulse, adding electric arc, bombarding by ions or electrons, etc.).

In the thermal evaporation deposition process, the material used to grow the film will be heated by the electric heater until it is converted into a gaseous state. PVD method spectrum also includes molecular beam epitaxy and ion beam sputtering coating. The film produced by the above method has high purity, excellent uniformity and strong adhesion to the substrate. PVD coating is more environmentally friendly than traditional electrochemical process, which can be widely used in many fields as an alternative to traditional electrochemical process.

PRODUCTS