Server-Online

137-1337-5955

13713375955

plastic

Plastic has the characteristics of light weight, excellent performance, easy molding, and easy processing, but at the same time it has the disadvantages of lack of metallic luster, low surface hardness, and easy aging. In order to further expand the use of plastic texture, it is necessary to coat the plastic surface. After coating, the plastic product has a strong metallic feeling and high brightness.

Acrylic

The use of vacuum coating technology in the acrylic industry has greatly expanded its use in various fields. Through PVD, acrylic products can show a good metallic texture and improve the appearance and decoration of acrylic products.

resin

The use of vacuum coating technology in the resin industry has greatly expanded its use in various fields. Through PVD, resin products can show a good metallic texture, which improves the appearance and decoration of resin products. At the same time, due to the metallization effect, Improve the mechanical strength of its surface.

plastic

Plastic has the characteristics of light weight, excellent performance, easy molding, and easy processing. It has a wide range of applications and is an indispensable material for daily life and various sectors of the national economy. However, it also has disadvantages such as lack of metallic luster, low surface hardness, and easy aging. . In order to overcome the existing shortcomings, improve the additional functions of plastics, and further expand the use of plastics, it is necessary to treat the plastic surface. The plastic products after coating have a strong metal feeling, high brightness, and less environmental pollution during the production process.

The use of vacuum coating technology in plastic, resin and other industries has greatly expanded its use in various fields. Through PVD, plastic products can show a good metal texture, improving the appearance and decoration of plastic products. At the same time, due to The metallization effect greatly improves its performance in terms of electricity, heat and corrosion resistance, and improves the mechanical strength of its surface. After the surface of plastic products is coated with a certain metal film layer by vacuum coating, it will have the color of the metal, so as to play a surface decoration function, such as aluminum, chrome, brass, stainless steel, etc. have different tones. Using plastic instead of metal to produce some parts with complex shapes can save a lot of processes, improve work efficiency and save a lot of metal materials. If the coating layer is aluminum, it can also be colored by paint or other methods to obtain various colors, and the decorative effect is very good.

Generally, the process of vacuum coating for plastic and other products is: surface cleaning → static electricity removal → spraying primer → baking primer → vacuum coating → spraying topcoat → baking topcoat → packaging.

Acrylic

The use of vacuum coating technology in the acrylic industry has greatly expanded its use in various fields. Through PVD, acrylic products can show a good metallic texture, improving the appearance and decoration of acrylic products. At the same time, due to the metallization effect , so that its performance in terms of electricity, heat and corrosion resistance has also been greatly improved, and the mechanical strength of its surface has been improved. After the surface of acrylic products is coated with a certain metal film layer by vacuum coating, it will have the color of the metal, so as to play a surface decoration function, such as aluminum, chrome, brass, stainless steel, etc. have different tones. Using acrylic instead of metal to produce some parts with complex shapes can save a lot of processes, improve work efficiency and save a lot of metal materials. If the coating layer is aluminum, it can also be colored by paint or other methods to obtain various colors, and the decorative effect is very good.

resin

The use of vacuum coating technology in the resin industry has greatly expanded its use in various fields. Through PVD, resin products can show a good metallic texture, improving the appearance and decoration of resin products. At the same time, due to the metallization effect , so that its performance in terms of electricity, heat and corrosion resistance has also been greatly improved, and the mechanical strength of its surface has been improved. After the surface of the resin product is coated with a certain metal film layer by vacuum coating, it will have the color of the metal, so as to play a surface decoration function, such as aluminum, chrome, brass, stainless steel, etc. have different tones. If the coating layer is aluminum, it can also be colored by paint or other methods to obtain various colors, and the decorative effect is very good.

Zhicheng Technology

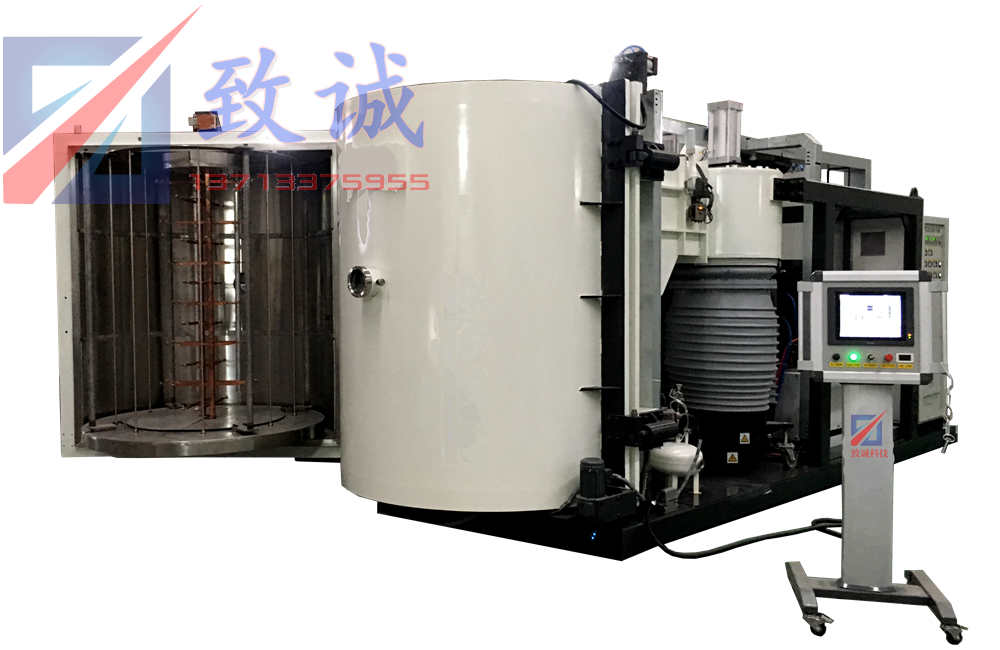

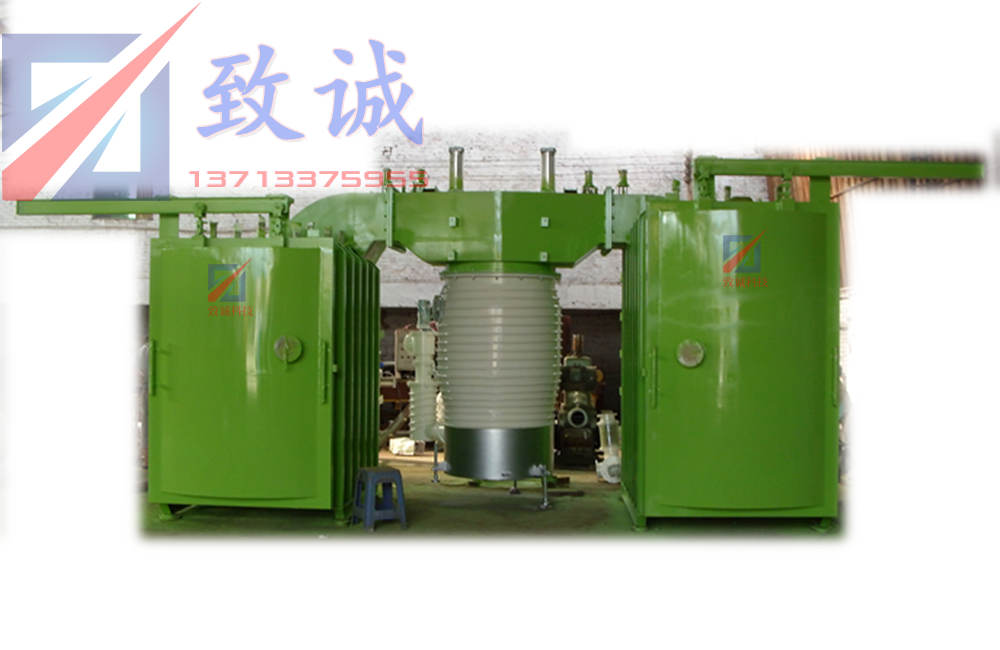

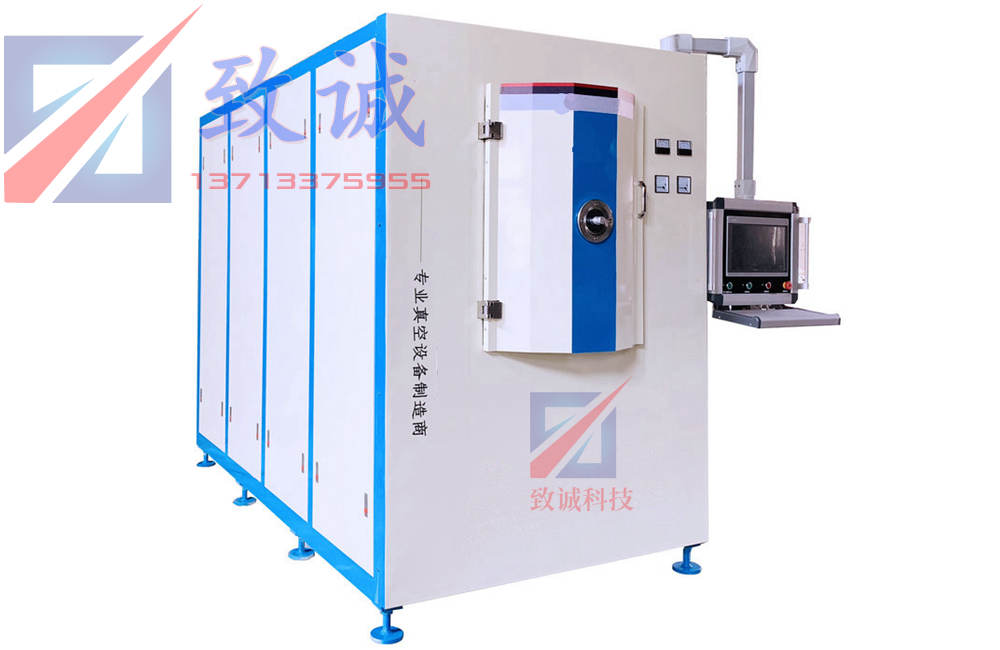

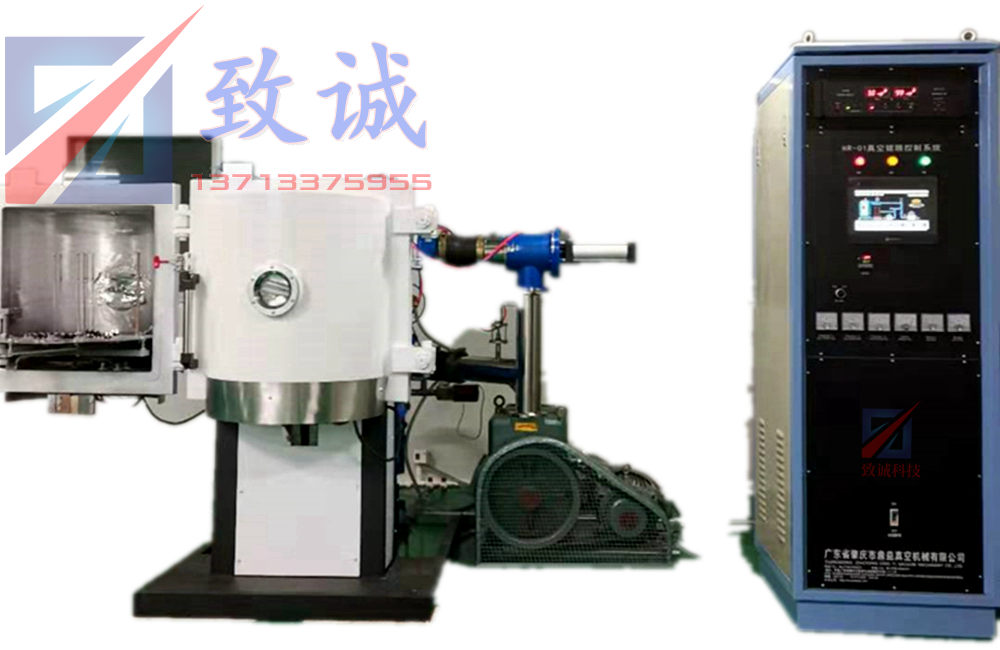

Vacuum coating machines of various specifications and models can be designed according to user requirements.

The vacuum unit and electronic control system can also be designed and configured according to user requirements.

Zhicheng Technology's world-leading coating application solutions: provide equipment, materials, processing, technology, project support and other system services

Zhicheng vacuum coating equipment includes: evaporation coating machine, magnetron sputtering coating machine, magnetron evaporation dual-purpose coating machine, multi-arc ion coating machine, intermediate frequency ion coating machine, AF coating machine, super hard coating coating machine, winding Type coating machine, PVD coating line, coating project supporting assembly.

PVD process technology uses vacuum conditions to deposit various metal and non-metal films on the surface of plastic parts by means of distillation or sputtering.

Zhicheng Technology matches the best coating process scheme according to the characteristics of the product.

The advantages and characteristics of Zhicheng vacuum coating machine ancestor equipment in the industry are: professionalism, integrity and reliability.

Vertical double-door-high vacuum evaporation coating machine

Horizontal evaporation coating machine

Vacuum coating machine for lamps

PVD aluminum mirror coating machine

AF anti-fingerprint coating machine

Vacuum internal plating equipment - evaporation coating machine - plastic/glass lampshade

Magnetic control evaporation dual-purpose coating machine

DC magnetron sputtering coating equipment

Plastic Metallization - High Vacuum Evaporation Coating

Common sense of vacuum coating VS silver mirror spraying

Evaporation Coating Machine - Handicraft Electroplating

Symphony/Colorful Plating-Vacuum Coating Equipment-Evaporation Coating Machine

UV electroplating processing line - resistance evaporation vacuum coating machine

Vacuum evaporation coating machine_plastic metallization UV electroplating processing technology

Cosmetic Shell Electroplating_Evaporation Coating Machine_PVD Vacuum Coating Equipment

Automobile and motorcycle electroplating, refurbishment, repair and modification__Wheel hub magnetron sputtering vacuum coating machine

Jewelry AFAR anti-fingerprint_medium frequency evaporation vacuum coating machine equipment

Evaporation magnetron dual-purpose vacuum coating machine

Technical Introduction of Resistance Evaporation Vacuum Coating Machine

Silicone oil protective coating equipment for car lamps - lampshade/reflector cup vacuum coating

Dongguan City, Guangdong Province, China

+86 137-1337-5955

+86 13713375955 (Mr. Deng)

dgzhicheng@gmail.com

Copyright © 2022 Dongguan Zhicheng Technology Co., Ltd.