Server-Online

137-1337-5955

13713375955

Introduction to basic knowledge of PVD coating of vacuum coating machine

2023-03-03

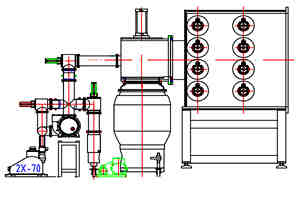

PVD (Physical Vapor Deposition) technology is mainly divided into three categories, vacuum evaporation coating, vacuum sputtering coating and vacuum ion coating. Compared with the three classifications of PVD technology, the corresponding vacuum coating equipment also includes vacuum evaporation coating machine, vacuum sputtering coating machine and vacuum ion coating machine.

Vacuum conditions in the process of vacuum evaporation coating machine

2023-03-03

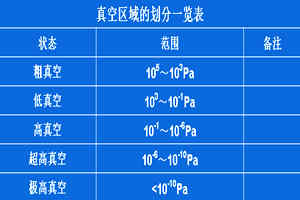

In the vacuum chamber, when the particle concentration in the gas phase and the pressure of the residual gas are low enough, these particles can keep flying in a straight line from the evaporation source to the substrate, otherwise, they will collide and change the direction of motion.

The vacuum coating machine can be classified according to the function of the vacuum furnace

2023-03-03

Vacuum coating equipment is distinguished according to the principle of thin film: it can be divided into sputtering coating, ion coating, evaporation coating and chemical vapor deposition coating. According to the purpose of application, it can be divided into optical coating, winding coating, decorative coating, solar heat collector coating, tool coating, architectural coating, conductive coating and so on. the

How does the vacuum coating equipment technology make gradient colors?

2023-03-03

Standing at the forefront of market and consumer requirements, bold design can be invincible. Vacuum coating equipment processing gradient color can be said to be a popular color this year. Since the Huawei P20 was sold, everyone has confirmed that gradient color has been a design trend in the past two years.

Why use high-purity gas in vacuum coating

2023-03-03

After high-purity coating metal (such as aluminum) is evaporated at high temperature, it will freely fly away and settle on the surface of the workpiece to form a coating. Argon is a protective gas to prevent the oxidation reaction from affecting the coating quality. In the work of vacuum ion coating equipment, the color of liquid gas will be different when different gases are selected.

2023-03-03

With the progress of society, vacuum coating machine technology is also changing with each passing day. Optical coating technology, winding coating technology, decorative coating technology, and magnetron coating technology have already been put into market use in large quantities to meet the current market demand.

Encyclopedia of various vacuum pump technologies, a must-read for vacuum coating equipment engineers

2023-03-03

A vacuum pump is a device that uses various methods to generate, improve and maintain vacuum in a closed space. A vacuum pump can be defined as a device or device that uses mechanical, physical, chemical or physicochemical methods to evacuate the evacuated container to obtain a vacuum.

How to measure the film thickness of vacuum coating?

2023-03-02

Many daily necessities are coated with a layer of film by a coating machine, making the product not only more beautiful, but also more practical. But many people have a question, since it is coated with a layer of film, the film must have a thickness, so how thick is the film thickness, and how to measure it?

Dongguan City, Guangdong Province, China

+86 137-1337-5955

+86 13713375955 (Mr. Deng)

dgzhicheng@gmail.com

Copyright © 2022 Dongguan Zhicheng Technology Co., Ltd.