Server-Online

137-1337-5955

13713375955

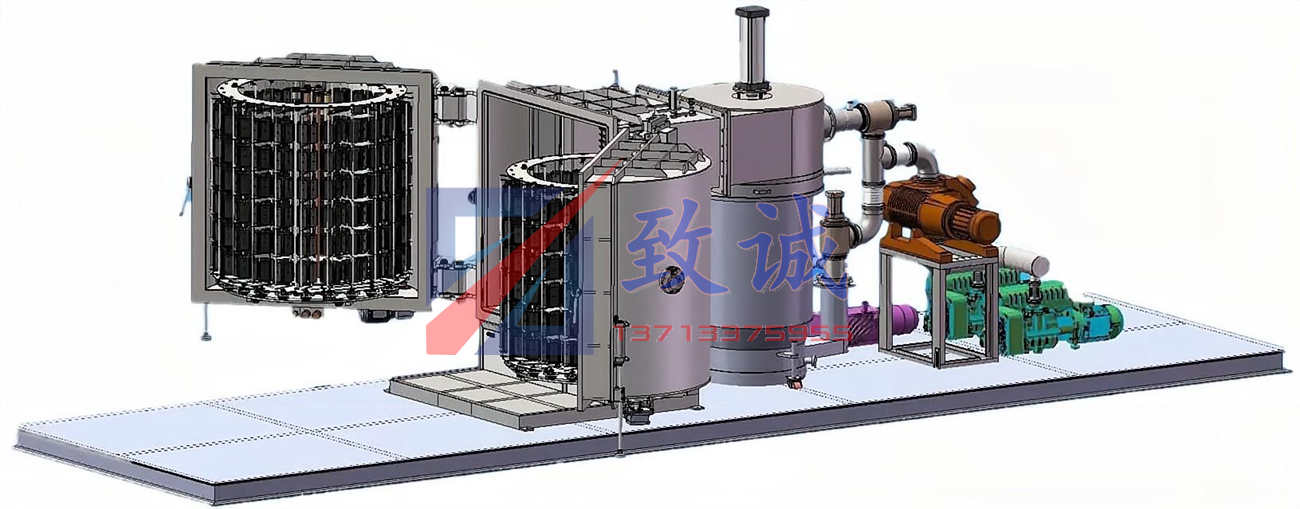

EMI shielding coating machine

PVD Vacuum Coating Machine

Magnetron sputtering coating machine

PVD vacuum coating equipment

Shielding film vacuum coating machine

EMI shielding PVD coating machine

EMI Shielding Vacuum Coating Machine

EMI coating vacuum coating machine

Shield Coating Vacuum Coating Machine

Functional Vacuum Coating Equipment

Magnetic control evaporation dual-purpose coating machine

PVD magnetron sputtering coating machine

EMI Shielding Vacuum Plating Equipment

EMI shielding vacuum coating equipment

Functional Vacuum Coating Equipment - Magnetron Sputtering Coating Machine - EMI Shielding Vacuum Coating Machine

Equipment introduction

Application of electromagnetic interference (EMI) shielding metal.

Other industries requiring electromagnetic interference shielding function

Substrate material. ABS, PC, PC+ABS, plastic, etc.

EMI shielding film characteristics

.Film thickness: 1.5~3 microns, depends on requirements.

.Thin film resistors. (ohm) better than 0.5Ω

.Adhesion: 3M810 tape>5B

.EMI shielding film coating process

.DC sputtering stainless steel

.Copper deposition by thermal evaporation

.DC sputtering stainless steel, completely covered on the Cu film layer.

Functional coating equipment sputter evaporation coating machine is specially designed for EMI shielding thin film deposition, widely used in telecommunications equipment, computers, laptops, consumer electronics, household appliances, mobile phone casings, laptop casings, radar speed measuring instruments, car video components, aerospace, military items.

Features

1) Double door structure and fast pumping speed for high productivity

2) User friendly touch screen panel and PLC control

3) User-friendly software program design, stable production and high quality.

4) High utilization rate of sputtering target ensures low production cost.

5) Good uniformity & excellent adhesion

6) Advanced design concepts to improve production efficiency and quality rate with better performance.

7) The ion source device is used for plasma cleaning and surface active treatment to improve adhesion.

8) Through the Polycold-water vapor cryopump, the high vacuum pumping time is shortened by 25% to 75%. Reduce water vapor partial pressure during processing for higher film quality, better adhesion and more repeatable deposition.

Zhicheng Vacuum Technology: Magnetron Sputtering Coating Machine

| Equipment main parameters | |

| Vacuum chamber size: | Φ1000mm 、Φ1200mm 、Φ1400mm 、Φ1600mm 、Φ1800mm 、 Φ2000mm |

| Vacuum system: | Rotary vane pump + Roots pump + diffusion pump + maintenance pump (or molecular pump, cryogenic pump, cryogenic system) |

| Ultimate vacuum: | 6x10-4Pa |

| Work Rotation | Multi-axis planetary rotation, frequency conversion speed regulation (controllable and adjustable) |

| cooling method | Water cooling circulation mode, additionally equipped with industrial cooling water tower or industrial chiller (refrigerator) or cryogenic system. (customer provided) |

| control method | PLC+touch screen operation or computer control, manual, semi-automatic, automatic |

| supply index | Air pressure 0.5-0.8MPa, water temperature ≤ 25 ℃, water pressure ≥ 0.2MPa |

| Alarm and Protection | Alarm for abnormal conditions such as water shortage, over-current and over-voltage, and open circuit of pumps and targets, and implement corresponding protection measures and electrical interlock functions |

| Pumping time: | No-load atmospheric pumping to 5x10-3Pa,>13min |

| Remark: | he above equipment parameters are for reference only, and the details are designed and customized according to the actual process requirements of customers. |

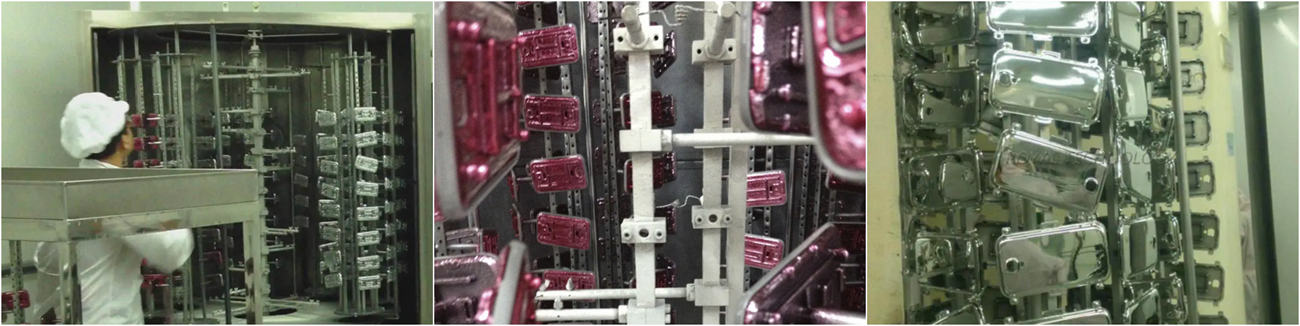

Coating case

Zhicheng Technology

Vacuum coating machines of various specifications and models can be designed according to user requirements.

The vacuum unit and electronic control system can also be designed and configured according to user requirements.

Zhicheng Technology's world-leading coating application solutions: provide equipment, materials, processing, technology, project support and other system services

Zhicheng vacuum coating equipment includes: evaporation coating machine, magnetron sputtering coating machine, magnetron evaporation dual-purpose coating machine, multi-arc ion coating machine, intermediate frequency ion coating machine, AF coating machine, super hard coating coating machine, winding Type coating machine, PVD coating line, coating project supporting assembly.

PVD process technology uses vacuum conditions to deposit various metal and non-metal films on the surface of plastic parts by means of distillation or sputtering.

Zhicheng Technology matches the best coating process scheme according to the characteristics of the product.

The advantages and characteristics of Zhicheng vacuum coating machine ancestor equipment in the industry are: professionalism, integrity and reliability.

Plastic Metallization - High Vacuum Evaporation Coating

Common sense of vacuum coating VS silver mirror spraying

Vacuum evaporation coating machine_plastic metallization UV electroplating processing technology

Jewelry AFAR anti-fingerprint_medium frequency evaporation vacuum coating machine equipment

Evaporation magnetron dual-purpose vacuum coating machine

Technical Introduction of Resistance Evaporation Vacuum Coating Machine

Silicone oil protective coating equipment for car lamps - lampshade/reflector cup vacuum coating

Dongguan City, Guangdong Province, China

+86 137-1337-5955

+86 13713375955 (Mr. Deng)

dgzhicheng@gmail.com

Copyright © 2022 Dongguan Zhicheng Technology Co., Ltd.