Server-Online

137-1337-5955

13713375955

Ion vacuum coating machines occupy a large proportion of market applications. As long as you have been in contact with the staff in the vacuum industry, most of them have heard of ion coating technology and ion vacuum coating machines. The tableware, kitchen utensils, furniture, toys, and daily decorations that are closely related to our daily life have been coated with a layer of film by an ion vacuum coating machine. This technology and equipment has become an indispensable indirect necessity in our life. It subtly affects our lifestyle and habits. So what about the ion vacuum coating machines that are commonly used in daily life, and the specific application to products, including what effect will appear after coating a layer of film.

Zhicheng Technology will introduce you in detail

Currently on the market, the ion vacuum coating machine is often divided according to the application field. The most common ones are: stainless steel plate ion vacuum coating machine, hardware decoration ion coating machine, ceramic tile ion vacuum coating machine, and ceramic ion coating machine. The fields of application are different, and the names are not the same, but the coating principle is probably similar, but there are some differences.

For example, the tile ion coating machine is mainly used for ceramic tiles, tiles, daily-use ceramic products (such as tableware, stationery), craft ceramics (such as vases, figures, ornamental decorations), etc., such as tableware, tea sets, coffee sets, and wine sets. , tableware, stationery, etc. It is widely used in daily-use fine porcelain, daily-use ordinary porcelain, daily-use stoneware, bone china, Linglong daily-use porcelain, underglaze (medium) color daily-use porcelain, and daily-use fine pottery. Stainless steel ion coating machine, stainless steel decorative plate ion coating machine is specially designed for the decorative film layer of ion plating on stainless steel decorative plate.

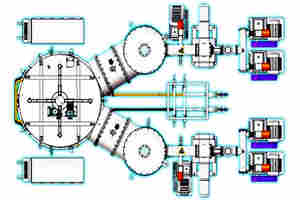

The diameter of the plating room of this series of equipment is 1800~2300mm, the height is 3600~4400mm, and it can plate 3 sheets of 1220x4000mm at a time; it is equipped with three sets of large suction vacuum units, with fast pumping speed and short working cycle; Reasonable layout of positions, equipped with pulse bias system, good film adhesion, uniform color, touch screen + PLC, can realize computer automatic control, automatic/manual switching at any time, reliable and stable operation performance. This series of equipment is safe, environmentally friendly, and the process is stable. The film layer is rich in color, uniform in color, wear-resistant, corrosion-resistant, high-temperature resistant, good adhesion and not easy to fade. TiN titanium gold decorative film can be plated; TiC, CrC gun black, black, gray series film; ZrN zirconium gold, champagne gold, brass series film; TiCN rose gold, rose red, wine red, brown series film Layer; TiO sapphire blue, emerald green, pink, rainbow color series coatings are widely used in stainless steel plates, stainless steel pipes (up to 6 meters), stainless steel display racks, stainless steel LOGO signs, locks, handles, hardware bathrooms, stainless steel tableware and other stainless steel products and Surface coating process of plastic electroplating parts, ceramics, etc. The principles of the two are similar, but there are some subtle differences.

So what effect will the ion vacuum coating machine have on the surface of the product? To give you a few simple examples:

The process used is the same as that used by the stainless steel ion coating machine, but the stainless steel will have an extra bias power supply, so there will be differences. Therefore, both ion vacuum coating machines have different coating principles.

Watches:

High-end watches will be covered with real gold or rose gold on the strap or case to show their dignity. The film plated by ion plating technology has excellent strength and excellent gloss.

Tableware:

The ion coating machine coats the titanium alloy on the tableware, which enhances the overall sense of grade. Most titanium alloys will not cause damage to the human body, so it can be said to be a very healthy and environmentally friendly material.

Mold:

For the mold of many products, it needs to have high strength and corrosion resistance. Therefore, an ion coating machine is required to coat the outer layer, so that its hardness, strength, wear resistance and corrosion resistance can be enhanced to a certain extent.

Lighting:

Crystal lighting combined with brilliant colors brought by ion coating technology makes the overall lighting and decoration effect more rich and elegant. And the outer coating can make the lighting performance tend to be stable.

Ceramics: Ceramics have certain stain resistance and corrosion resistance. The purpose of re-coating the outer layer by the ion coating machine is to further increase its gloss and strength.

There are reasons why the ion vacuum coating machine has such a wide range of applications and such a high market share. It not only changes the appearance of the product, but also changes its performance, which provides great convenience and quality for our life, and makes our life more colorful.

What is the difference before and after the workpiece is plated by the vacuum coating machine?

2023-03-11

What is the difference before and after the workpiece is plated by the vacuum coating machine?

2023-03-11

Vacuum coating machines are widely used in various industries, including machinery, electronics, hardware, aerospace, medical, chemical and other fields.

Vacuum coating machine design should pay attention to details

2023-03-03

Vacuum coating machine design should pay attention to details

2023-03-03

In order to ensure that the vacuum coating machine has good sealing performance, it is necessary to cut off the cause of possible leaks at the source

How to check for leaks during installation and commissioning of vacuum coating machine

2023-03-03

How to check for leaks during installation and commissioning of vacuum coating machine

2023-03-03

The leak detection link of the vacuum coating machine is a step that needs to be carried out in all links from design, manufacture, commissioning, use, etc., and it is absolutely necessary.

Vacuum coating machine sputtering sputtering process introduction

2023-03-03

Vacuum coating machine sputtering sputtering process introduction

2023-03-03

The sputtering method can be used to prepare material films with high melting point and low vapor pressure that cannot be prepared by the evaporation process, which is convenient for the preparation of thin films of compounds or alloys. The vacuum coating machine sputtering sputtering process is mainly used for sputtering etching and film deposition. .

Dongguan City, Guangdong Province, China

+86 137-1337-5955

+86 13713375955 (Mr. Deng)

dgzhicheng@gmail.com

Copyright © 2022 Dongguan Zhicheng Technology Co., Ltd.